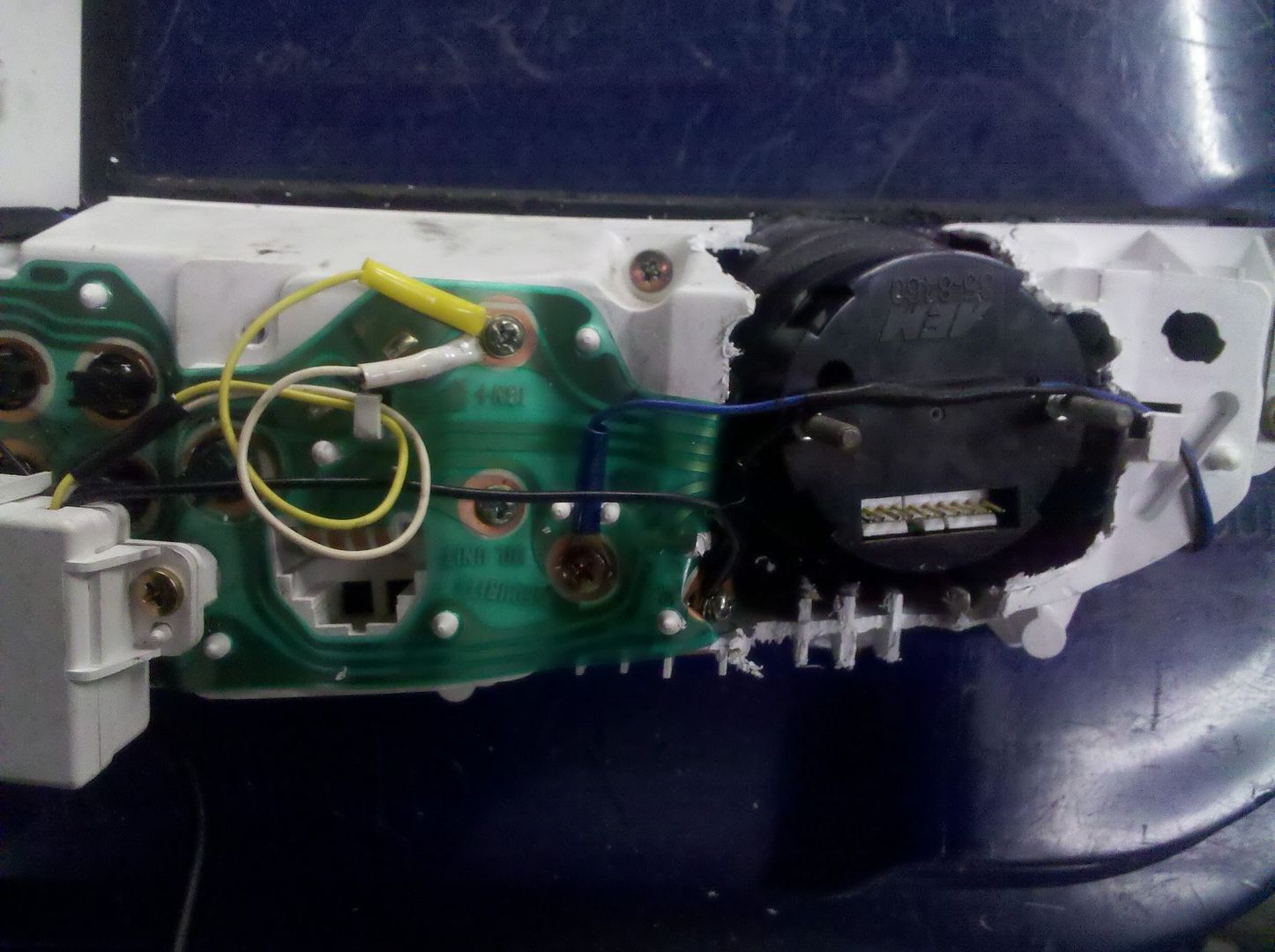

SURUKO;1622958 said:Is this done yet??Need more pics of the nawz toggle switches :biglaugh:

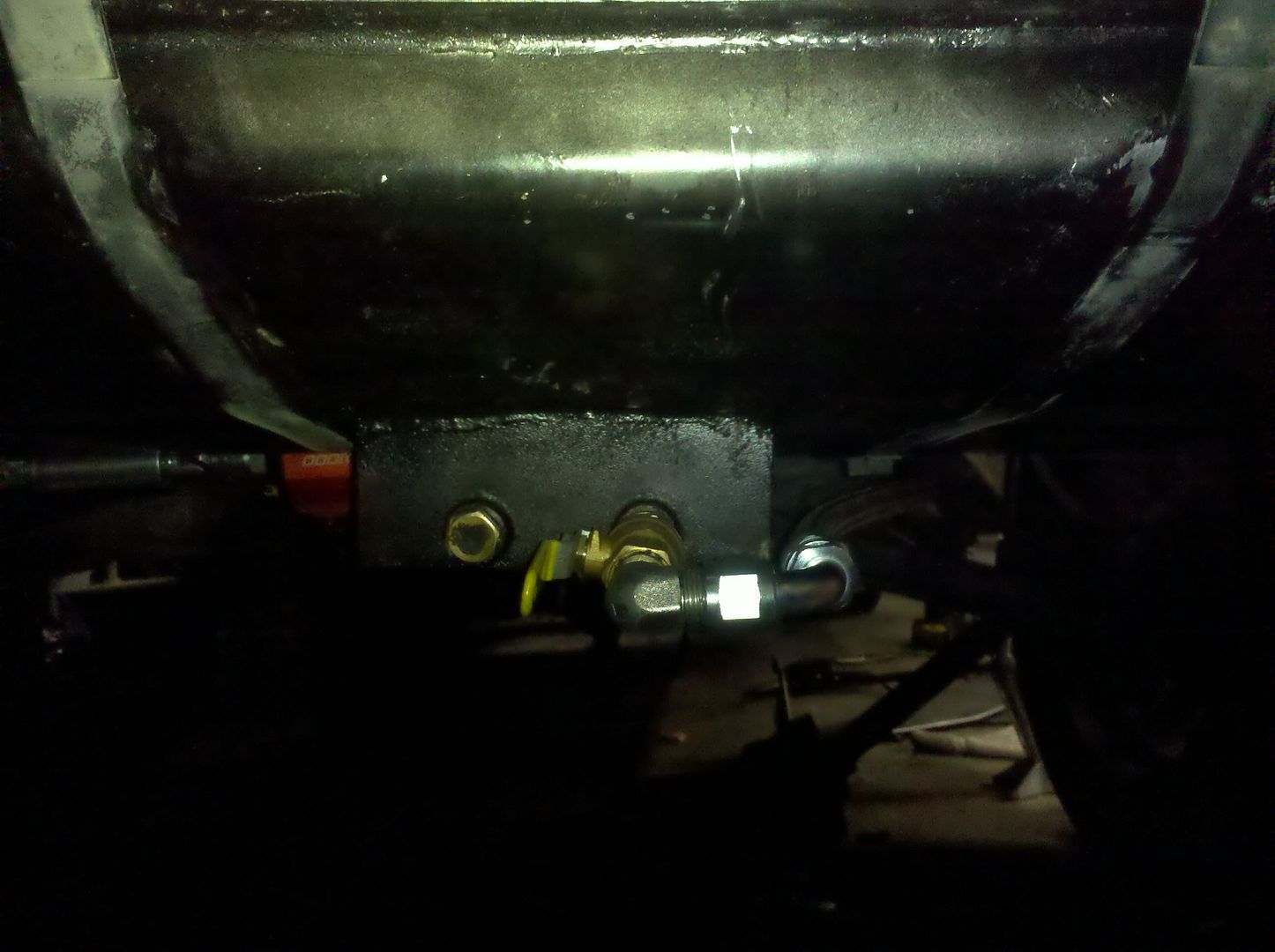

Lol that switch is for my fuel pump purge and constant but I'm probably going to just wire it up to my stand alone lol

Sent from my Droid using Tapatalk

SURUKO;1622958 said:Is this done yet??Need more pics of the nawz toggle switches :biglaugh:

honestabe;1625709 said:Soooo much better. Definitely must have been sniffing gas fumes at the time

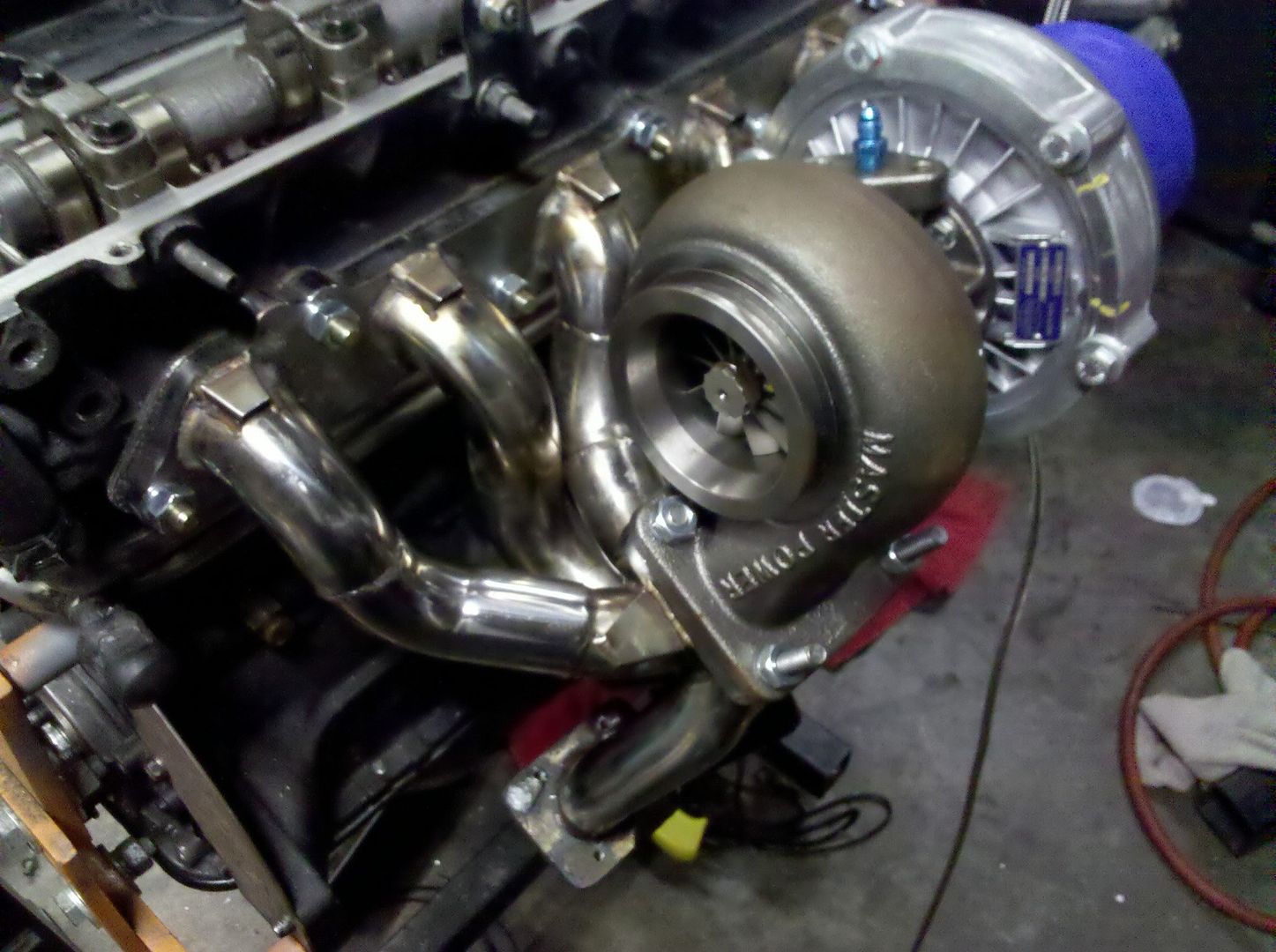

honestabe;1627610 said:I think I do, I'd have to check. Definitely wrap the manifold. Doing so properly will help increase power and keep engine bay temps down.

IJ.;1636106 said:Each 90 fitting is = to 10 feet of straight hose for resistance to flow.....

At least use 90 sweeps NOT elbows..

honestabe;1636107 said:Glad my brake lines went to a good home. They've been collecting dust in the bag for a year now.

thedave925;1636945 said:Wrong orders BOOO!!!

Great example why customizing things makes projects take so long.

I feel you on the valve cover bolt, mine disappeared into thin air when I went to check torque values at the studs.

northwestsupra;1636116 said:haha ya np man. so when i get paid lol no hurry