^keep us updated, seems the WG flap could be a more widespread problem given your buddy's situation.

T61 Bolt on Turbo by Cx Racing

- Thread starter Steve_N

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zazzn;1583204 said:Hey guys,

my buddy just put this turbo on his car his car seems really lazy, and doesn't boost much of anything until about 5000 RPM. It was at a shop and I was trying to help him out with tuning. We couldn't get more then 1.1 bar of boost even with the WG not connected to a VAC line.

After reading all about this I'm thinking first he has a boost leak, and second it could be the WG leaking air as well. His results at 1.1 bar was 356 WHP and 299 tq I think. Really really lazy power curve made peak power at redline.

Anyways, I'll keep you guys posted on what this turbo will do once we do a pressure test on the intercooler pipes. If that shows nothing the turbo will come off and I'll tell them to inspect the WG flapper and pre load it to about 15 PSI.

Good info!

Pm me if you have any questions

i preloaded mine to around 10-12psi (10psi starts to open and fully open by 12)

Keep us posted and make sure you email CX racing and let them know. Check for flapper movement as well

Before we fixed the turbo I recorded a video of the issue, no one make fun of my Aussie accent

http://www.youtube.com/watch?v=LCEMLCFRwls

Last edited:

So Paradox-

Given your experience with this turbo and its performance, and you had the chance to do it all over again-

Would you still stick with this T61, or go with a modified Ct26 (57 or 60 trim)?

Given your experience with this turbo and its performance, and you had the chance to do it all over again-

Would you still stick with this T61, or go with a modified Ct26 (57 or 60 trim)?

supraguy@aol;1585361 said:So Paradox-

Given your experience with this turbo and its performance, and you had the chance to do it all over again-

Would you still stick with this T61, or go with a modified Ct26 (57 or 60 trim)?

This T61 anyday. a 57trim doesn't suit my power goals anyway, i've got a spare 57trim in my shed, it didn't pack the same punch this turbo does, There was a few small issues but nothing insurmountable and not all related to the turbo its self, infact the only issue i've had with it is the wastegate flapper arm & preload.

paradox616;1568239 said:1) I had my exhaust from turbo back made on the car by a few guys i know that run a exhaust shop, divorced downpipe until the floor pan pretty much. as poodles said, stock is a horrible design, i got the flange lazer cut and a 3" pipe all the way to the end tailpipe.

2) don't use the bolts that come with it, they are weak and most likely will snap when you go to undo them after running for a while, use some high tensile metric studs and nuts, Correct about centering, i lined it up the flange and use a jack to support the dump pipe then tightened the bolts, the casting isnt too bad on the exhaust housing.

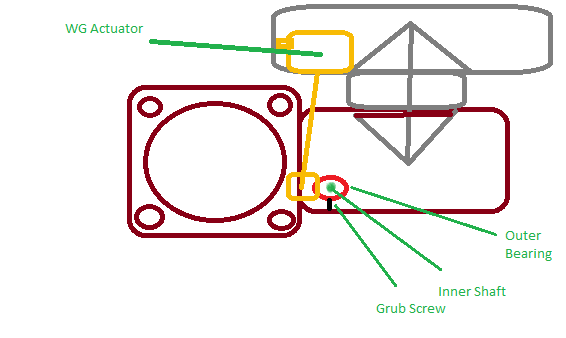

to follow up on the wastegate flapper arm sliding issues, here are some close up pictures, compare the flapper position in each picture and the circled section

Here is a picture of my setup, apart from my braided lines it tucks away nicely and could almost pass for stock.

So does power come in at around the same rpm with the T61, as it did with the 57 trim?

My power goals really aren't past 400hp, and Id rather get power at lower rpm, if one spools faster than the other.

My power goals really aren't past 400hp, and Id rather get power at lower rpm, if one spools faster than the other.

The only thing so far that is keeping me from running this turbo, is the wastegate issue. How difficult is this to resolve?

paradox616;1585301 said:Pm me if you have any questionsI've got a pretty good result out of it, i get 1 bar boost in first gear.... sounds exactly like mine before we fixed it

i preloaded mine to around 10-12psi (10psi starts to open and fully open by 12)

Keep us posted and make sure you email CX racing and let them know. Check for flapper movement as well

Before we fixed the turbo I recorded a video of the issue, no one make fun of my Aussie accent

http://www.youtube.com/watch?v=LCEMLCFRwls

I understand now the issue. My question is, how did you fix it. I know you used a grub screw but the pic isn't very clear how this was used and installed. Mind going into a bit more detail?

Nghty89;1585828 said:The only thing so far that is keeping me from running this turbo, is the wastegate issue. How difficult is this to resolve?

Easy, i took the turbo, handed it to IJ and it was fixed

took no longer than about 10-20 minutes? He just drilled a hole through the housing on the flange surface and installed a grub screw, you only need to secure the outer bearing to stop the movement.

I guess if you're shooting for lower Hp it would be a good idea to fit a smaller turbo to regain responsiveness, My guess is ill get bored with 400rwhp and want 500rwhp.

paradox616;1586057 said:Easy, i took the turbo, handed it to IJ and it was fixed

took no longer than about 10-20 minutes? He just drilled a hole through the housing on the flange surface and installed a grub screw, you only need to secure the outer bearing to stop the movement.

I guess if you're shooting for lower Hp it would be a good idea to fit a smaller turbo to regain responsiveness, My guess is ill get bored with 400rwhp and want 500rwhp.

What exactly is a grub screw and how did you use it to resolve the problem? I agree, the pictures weren't clear enough.

paradox616;1586057 said:Easy, i took the turbo, handed it to IJ and it was fixed

took no longer than about 10-20 minutes? He just drilled a hole through the housing on the flange surface and installed a grub screw, you only need to secure the outer bearing to stop the movement.

I guess if you're shooting for lower Hp it would be a good idea to fit a smaller turbo to regain responsiveness, My guess is ill get bored with 400rwhp and want 500rwhp.

You cheated!!! We don't have IJ here in the states lol But I'm actually interested as well (in detail) on whats needed to be done, to resolve the problem

Nghty89;1586064 said:What exactly is a grub screw and how did you use it to resolve the problem? I agree, the pictures weren't clear enough.

google is your friend

Drilled a hole in the housing all the way to the outer bearing, and screwed this all the way in until it contacted the outer bearing and secured it in place.

Don't start that google mess with me... lol I had an idea of what it was. So once you drill that hole, it has to be tapped? Or can this be done without a tap? We need good pictures up close of before and after from the fix, does anyone have these? I understand the concept and could do it, but I'm sure others (and myself) will benefit from more detailed pictures.

Nghty89;1586369 said:Don't start that google mess with me... lol I had an idea of what it was. So once you drill that hole, it has to be tapped? Or can this be done without a tap? We need good pictures up close of before and after from the fix, does anyone have these? I understand the concept and could do it, but I'm sure others (and myself) will benefit from more detailed pictures.

Nah sorry I don't, only what's posted here. Sorry but I really can't be bothered pulling the turbo off to take more pictures and even if i could be bothered, im not sure i could take any that would help you. I'm pretty sure IJ didn't tap the hole just screwed it in.

Perhaps ill draw you a ms paint diagram.

EDIT: Here is a digram that might explain it a bit better.

Last edited:

I understand. Like I said, I understand the concept, but lack a spare turbo laying around so I could look at the flapper design. Sometimes I understand things better when I can actually work on them and sometimes I work better through reading... this happens to be one of the physical ones. lol

Thanks for that, it does help.

Thanks for that, it does help.

Nghty89;1586417 said:I understand. Like I said, I understand the concept, but lack a spare turbo laying around so I could look at the flapper design. Sometimes I understand things better when I can actually work on them and sometimes I work better through reading... this happens to be one of the physical ones. lol

Thanks for that, it does help.

That's alright, its a very similar set-up to a CT26 if you can get your hands on a spare one.

Paradox has taken great photos in this thread already that show exactly how the outer bushing moves up and down, changing the alignment of the flapper over the wastegate hole. I had thought that a small tack weld would accomplish the same thing. If it was not lined up exact when the tack was made, it would cause issues that would be more difficult to resolve. Thanks for the details on this fix, the T61 turbo is sitting in my room waiting to go on the car in early August.

CBatstone;1587865 said:Paradox has taken great photos in this thread already that show exactly how the outer bushing moves up and down, changing the alignment of the flapper over the wastegate hole. I had thought that a small tack weld would accomplish the same thing. If it was not lined up exact when the tack was made, it would cause issues that would be more difficult to resolve. Thanks for the details on this fix, the T61 turbo is sitting in my room waiting to go on the car in early August.

Thanks

I thought of a tack weld first but IJ thought a grub screw was the best way to tackle it.

There is no play that can be seen or felt by pushing it with my finger? Did yours move easily when you finally realized to try it? I also have not installed mine yet so there is the chance that this 'friction fit' gets loose once it gets heat cycled a few times. I will just tack it on or grub screw it from day one to eliminate any possibility of it moving in the future. Thanks for saving me time with this!! I'm going MAFTPRO with a whole new fuel system, turbo, injectors in early August so I'm getting ready for that. It's going to be a big learning curve with the tuning side thats for sure.