Update:

Tore the motor down last night in between working on manifolds. Still have to pull the rods and crank but that is pretty much it!

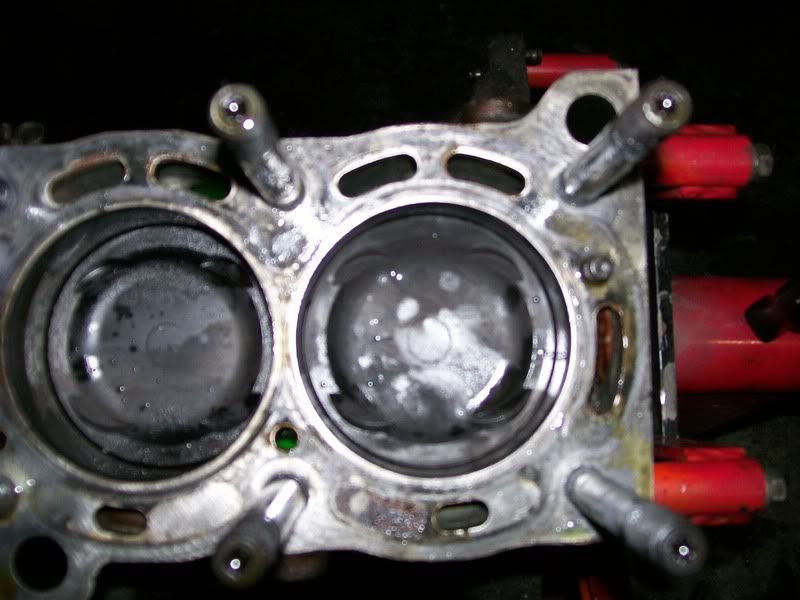

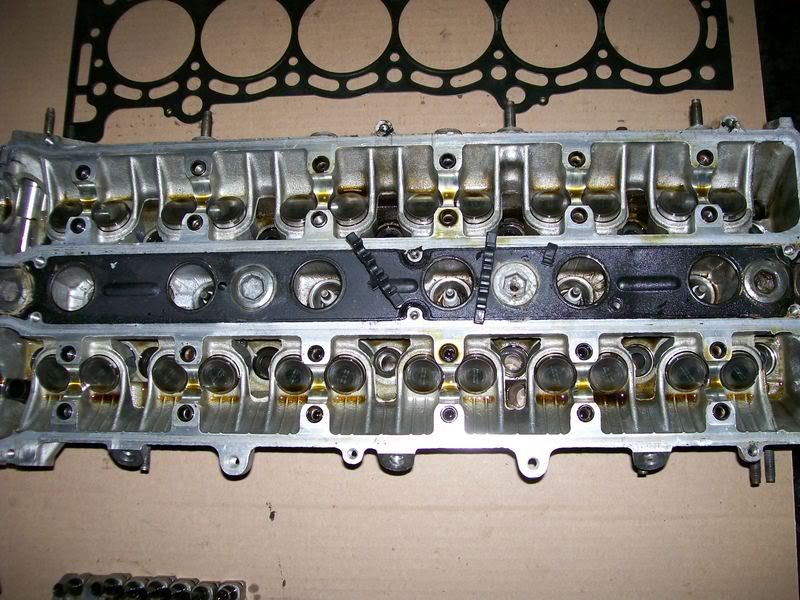

Upon teardown I discovered the #6 cylinder is dry. You can see in the pictures of both the top of the piston and the cylinder head are dry(bad injector?) The engine did not smoke at all but it had heavy blow by and the #6 cylinder was low on compression. I am guessing the compression rings are stuck yet the oil ring is still working fine.

Cylinder walls all look good! Also valves all look almost new and head has almost no carbon build up, you can still see the 7M on each valve. Also the cam lobs and bearing surfaces are almost perfect, will just take a little polishing!

Will tear the head apart and the rest of the bottom end tonight!

Here are pics:

#6 cylinder(bit of coolant spilt when the head came off not, otherwise DRY):

#Combustion chamber(Dry as well):

Others so you can see the wetness/darkness difference:

Cleanness of head!:

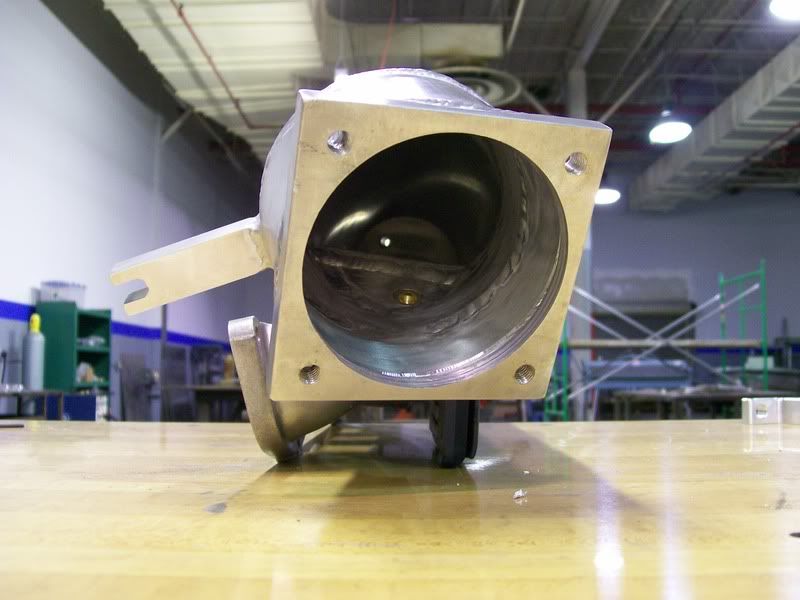

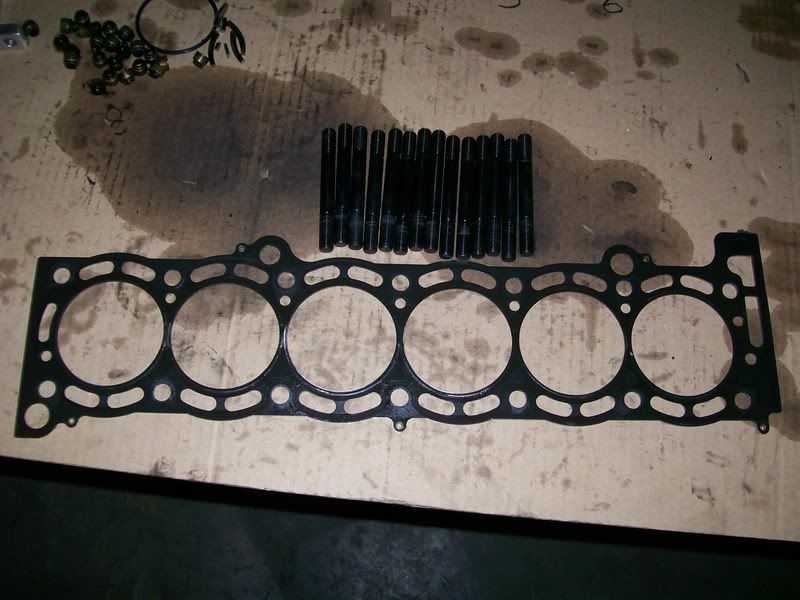

Parts all layed out:

Also looks like the MHG job was real recent as the head gasket had not even stuck to both sides yet and is nearly perfect! Also who ever put the ARP's in before did not know what they were doing as they were all torqued differently and all the studs were tightened differently.

IJ what you think the DRYness is caused by and what would cause the blow by without smoke?

Thanks,

Seth