Dropped my engine head off this morning to the machine shop. I wish I had brought them my exhaust manifold stud/heli coil kit from DM (some were stripped out) but ohh well. They'll deck the head, vacuum pressure test (valve sealing) and clean up the head little for me as well. Also, they'll bead-blast my exhaust manifold then I'll just paint it over it with some high temp black spray paint.

Also, I cleaned up some parts with brake cleaner and a red scuff pad. Decided to paint them giving it a freshened new look (valve cover lines are done in dark ford blue and everything else was silver); also painted my exhaust manifold heat shields (not shown in pics).

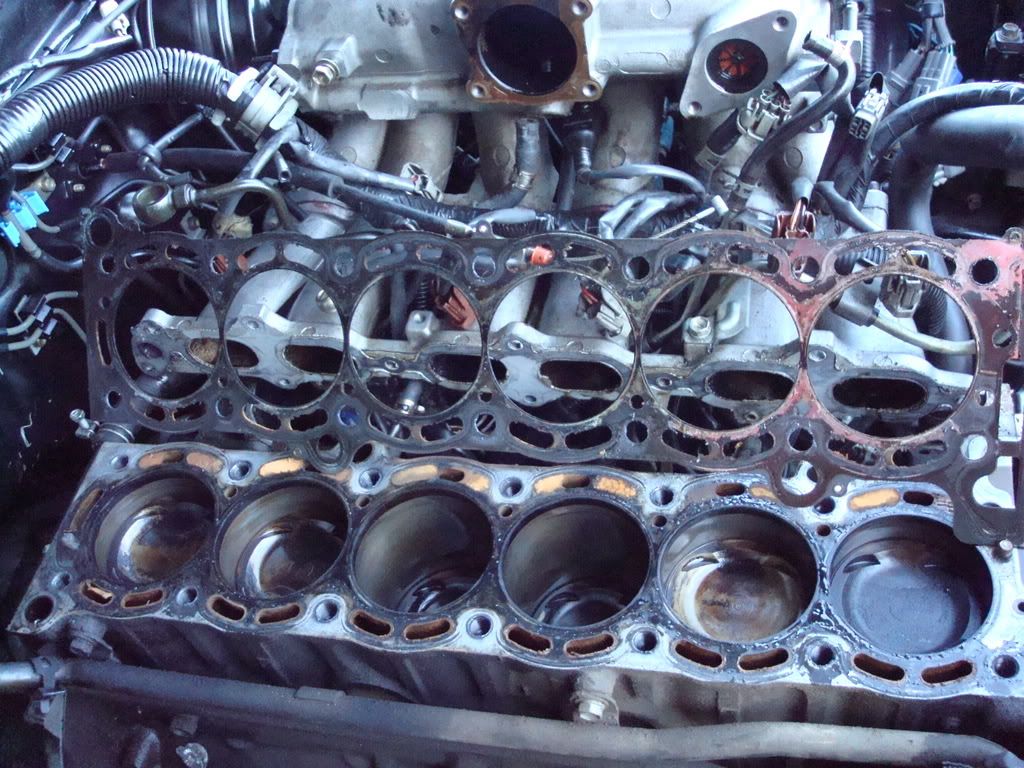

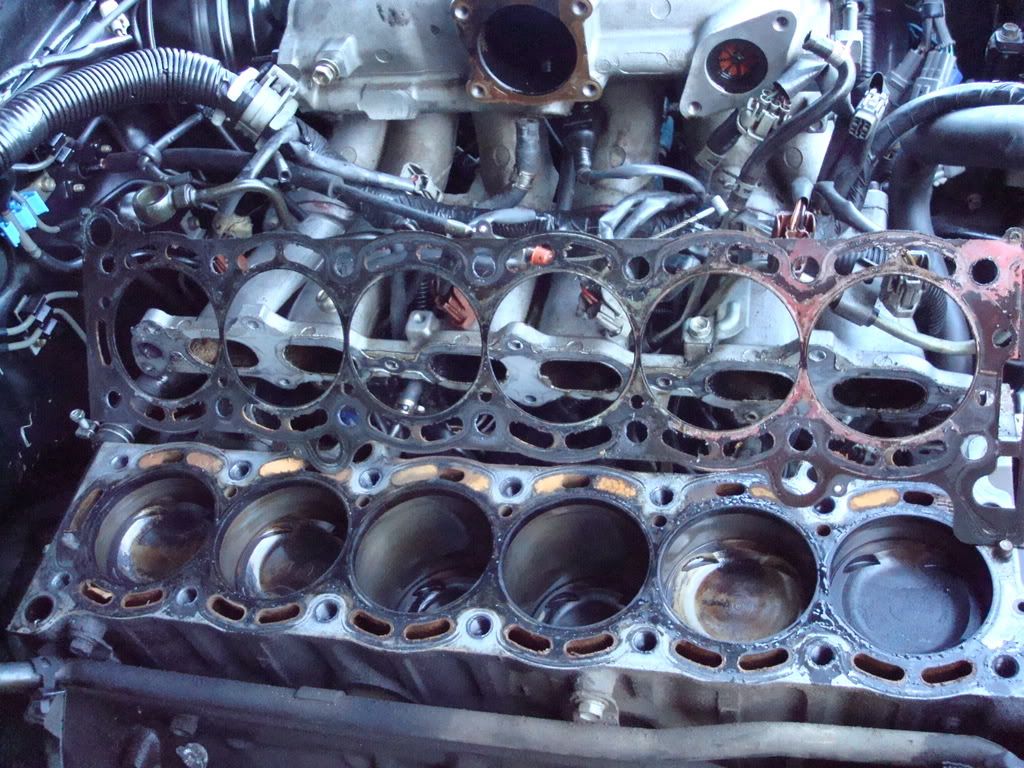

Also, here's the surface/deck of my block. I used a gasket scrapper and even a razor blade to scrap off the gasket material on the surface. However, I'm not too confident in the "finished" look/feel. I know its hard to tell with pictures but how does this surface look?? I'm thinking to block sand (VERY LIGHTLY) to get the surface gasket/crap off. Should I try that?? Or should I use some brake/carb cleaner on the surface and keep scrapping lightly with the razor blade?? Any suggestions?? I've never gone this far ever with an engine.

Also, I cleaned up some parts with brake cleaner and a red scuff pad. Decided to paint them giving it a freshened new look (valve cover lines are done in dark ford blue and everything else was silver); also painted my exhaust manifold heat shields (not shown in pics).

Also, here's the surface/deck of my block. I used a gasket scrapper and even a razor blade to scrap off the gasket material on the surface. However, I'm not too confident in the "finished" look/feel. I know its hard to tell with pictures but how does this surface look?? I'm thinking to block sand (VERY LIGHTLY) to get the surface gasket/crap off. Should I try that?? Or should I use some brake/carb cleaner on the surface and keep scrapping lightly with the razor blade?? Any suggestions?? I've never gone this far ever with an engine.