WHY can't people do things correctly?? So heres the story! I go to pick up the engine from the machine shop. Everything looks great. A little bit of discoloration on the deck, but according to the machine shop guy, its just fine for a MHG. Everything is superb. I pay him 280 dollars for all the machine work (decking head and block, honing, cleaning, and drilling and tapping the second knock sensor) Then I get it home. I was getting ready to paint the block. I was taking everything off the block. I get to the knock sensor, and I notice it is in the hole that he drilled, instead of the hole that it was in when i sent it in. I figured, alright. He was testing how it fit.

NOPE! It turns out that he tapped the hole to some unknown thread pitch, probably standard threads... Even though I told him it was M12x1.25, AND he had the knock sensor! Instead of listening to me, he figured "Oh, close enough, I'll tap it with this!" and went ahead and tapped it, took the knock sensor and powered it into the threads, ruining the threads on the knock sensor, and more importantly, never told me about this, and STILL CHARGED ME. AND he also didn't use a bottoming tap, so the knock sensor wont even seat down onto the block.

SO. Running cost of this mistake.

$20 for the job

$40 for helicoils

$180 for a knock sensor

I know many of you will say "Oh, whats $240 dollars. Forgive, forget, and move on." But to a highschool kid? That's quite a bit to just forget about. Any advice on how to remedy this, or are helicoils my only option?

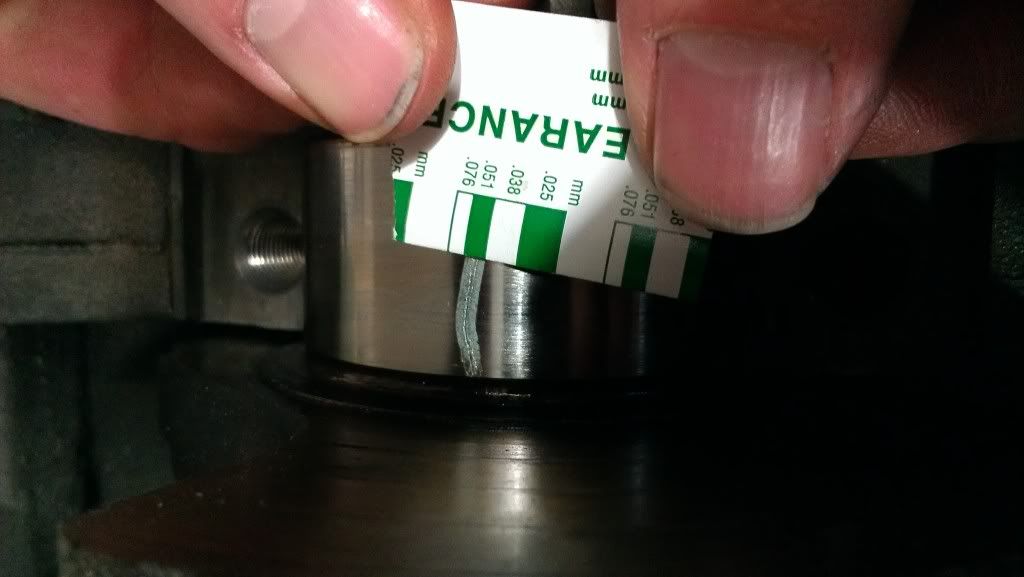

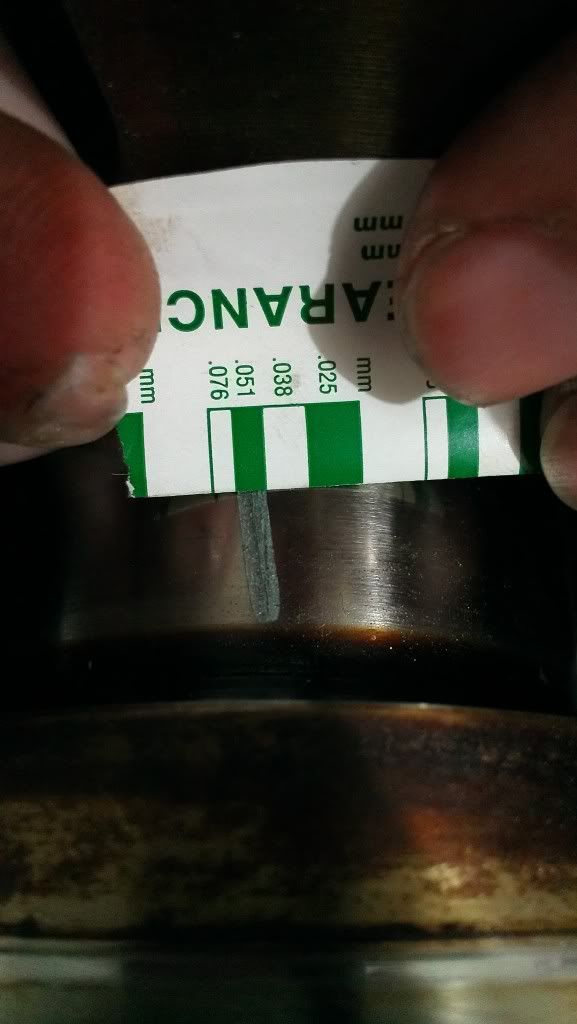

Also, My head gasket calculations come to 2.08mm for a head gasket. .028 inches removed from the head and block combined, which is .7112 in MM. .71+1.37=2.08. Correct in my calculations?

If so, would I be okay with going with the cometic 1.9mm head gasket?