Been a helluva ride last 3-4 weeks

Highlights:

-Wiper motor and brake lines reinstalled

-Went to a wedding

-Helping my gf with her business; struck a deal to ride horses with her (she's a trainer), and she wants me to walk her through building an engine (my spare 7m). Says if i don't finish in 2 months on my build she's gonna do it for me

-Helped suprastroker88, he started a build thread recently http://www.supramania.com/forums/showthread.php?127911-My-First-Build

-Drove a 2004 WRX, mildly modded with tuned 20g to ~12-16 psi

-Went for a hike

-Babysat a kid for my really good friends mom; mom had to take her daughter (kid's mother) on errands, i was near and said 'why not'

-Visited the machine shop

-Chilled with friends I hadn't seen in like 3 months (it goes fast)

-Witnessed a skydive; gf's client's husband setup a blind surprise bday trip, so we went and it was fun :] finished up having dinner at the Texas Roadhouse steak restaurant in Tracy

-And my gf went to hawaii for her sister's wedding, so i get to tool on the car for an week after work, uninterrupted (I like getting disrupted by her )

)

Bummer of the week:

The transmission on my work van has a small rattle on heavy accel leaving from a full stop, going forward only and noticeable in 1st and 2nd, i'm thinking on the output shaft.

Maybe a ring broke or something. i don't have 2500 for that to get rebuilt right now.

Pics:

Wiper motor removal is easiest popping the ball out of the joint on the wiper rod just behind the firewall.

The rod has a convenient catch to help with the reinstall; this is the way to do it without worry of reseting the arm on the motor itself

Wedding:

The bride is very pretty and kissed me on the cheek when i congratulated her at the banquet :icon_razz

Gf:

Helping suprastroker88 by bringing tools and engine hoist:

suprastroker88's buddy came through late in the day, handed me the keys with the explanation that my being a car guy is good enough

Hiking at Castle Rock, next to Mt. Diablo, Concord, California

A view over Concord, past Pittsburg and to Martinez and Vallejo beyond

Babysitting, baby's momma's brother is a cool dude, my best friend for 14+ years

He was doing upholstery out back and the kid likes music, and now hats too

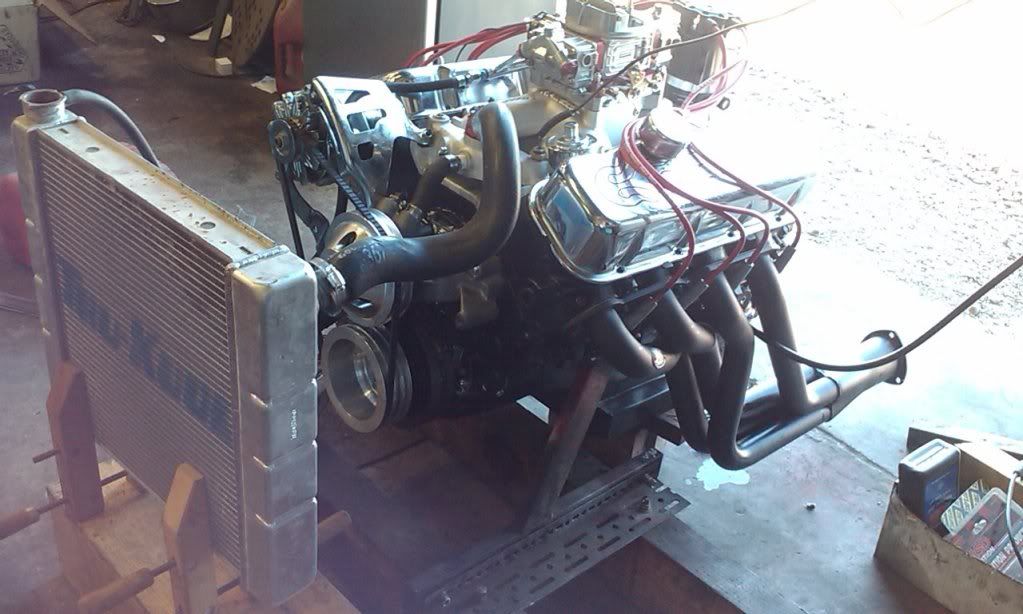

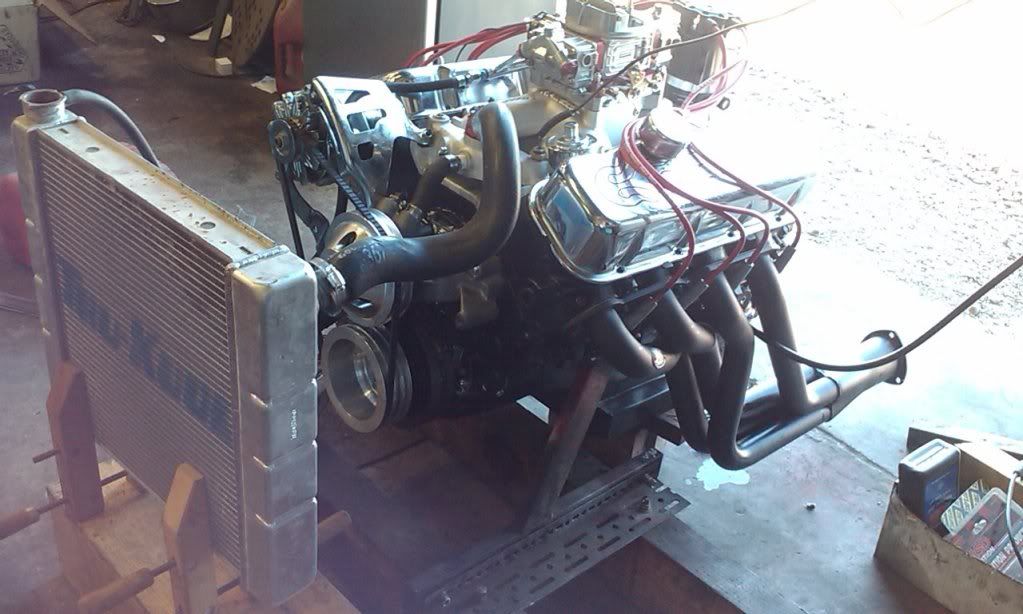

Machine shop stops always yield smiles:

454 tested before dropped off. Open headers out the back and a snappy throttle is GREAT!

Another gem I hadn't seen there before

Friends playing Kings cup. Yes, the jersy says 'Beast Mode', the dude is 225 and holds me in highest regards for keeping up with him @ gym.

The chick laughing is the baby's mama, dude to the right is father, left is my best friend, guy in white a really good friend i've known 6+ years.

I didn't get home til 5 cuz Denny's is open and we had extra beer when we got back lol

Skydive:

My phone didn't get any of the in-air divers, or formations...

Purple jumpsuit lady, it was her Bday. Her son is on the fence, my gf is wearing her hat, and the mother in law of the Bday skydiving girl

Roll up them 'chutes

Texas Roadhouse:

Bday girl in center, my gf to the right and close, bday girl's mother in law on left.

Its an inside joke between my gf and bday girl that they are Gfs; the husband sat across the table and my gf exclaimed she was lucky to be between both her lovers

Outside Texas Roadhouse:

I love fast cars, but I like the old too

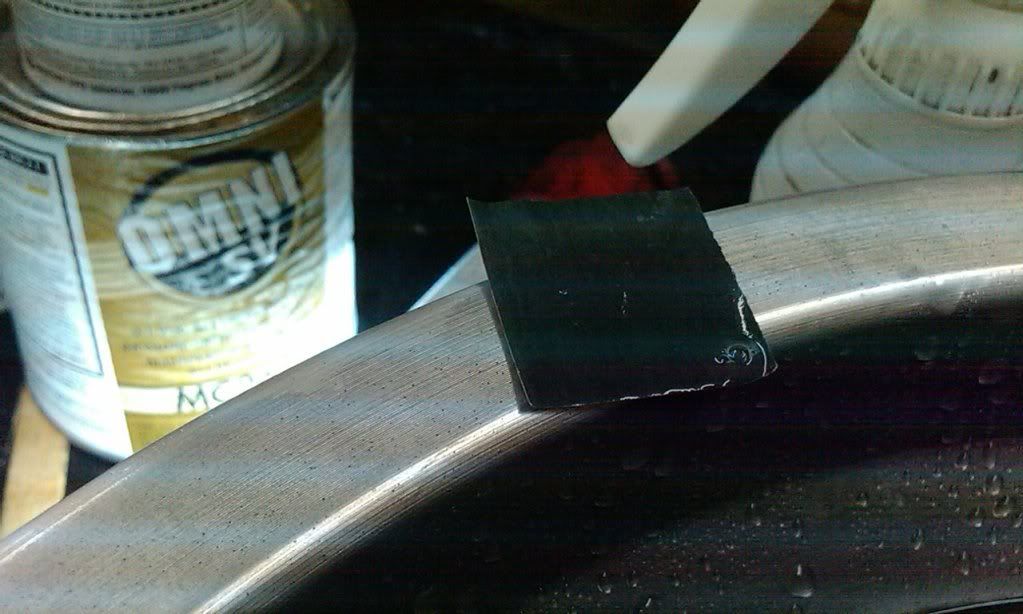

And I've been hired to paint rims for a friend

944 rim, paint stripped needing a polish to remove the oxidation on the machined lip

What its supposed to look like:

So I will turn over some money by painting rims before tooling on the supra.

I'm off to sort the collection in my garage to facilitate work, can't do anything with it so clustered

Highlights:

-Wiper motor and brake lines reinstalled

-Went to a wedding

-Helping my gf with her business; struck a deal to ride horses with her (she's a trainer), and she wants me to walk her through building an engine (my spare 7m). Says if i don't finish in 2 months on my build she's gonna do it for me

-Helped suprastroker88, he started a build thread recently http://www.supramania.com/forums/showthread.php?127911-My-First-Build

-Drove a 2004 WRX, mildly modded with tuned 20g to ~12-16 psi

-Went for a hike

-Babysat a kid for my really good friends mom; mom had to take her daughter (kid's mother) on errands, i was near and said 'why not'

-Visited the machine shop

-Chilled with friends I hadn't seen in like 3 months (it goes fast)

-Witnessed a skydive; gf's client's husband setup a blind surprise bday trip, so we went and it was fun :] finished up having dinner at the Texas Roadhouse steak restaurant in Tracy

-And my gf went to hawaii for her sister's wedding, so i get to tool on the car for an week after work, uninterrupted (I like getting disrupted by her

Bummer of the week:

The transmission on my work van has a small rattle on heavy accel leaving from a full stop, going forward only and noticeable in 1st and 2nd, i'm thinking on the output shaft.

Maybe a ring broke or something. i don't have 2500 for that to get rebuilt right now.

Pics:

Wiper motor removal is easiest popping the ball out of the joint on the wiper rod just behind the firewall.

The rod has a convenient catch to help with the reinstall; this is the way to do it without worry of reseting the arm on the motor itself

Wedding:

The bride is very pretty and kissed me on the cheek when i congratulated her at the banquet :icon_razz

Gf:

Helping suprastroker88 by bringing tools and engine hoist:

suprastroker88's buddy came through late in the day, handed me the keys with the explanation that my being a car guy is good enough

Hiking at Castle Rock, next to Mt. Diablo, Concord, California

A view over Concord, past Pittsburg and to Martinez and Vallejo beyond

Babysitting, baby's momma's brother is a cool dude, my best friend for 14+ years

He was doing upholstery out back and the kid likes music, and now hats too

Machine shop stops always yield smiles:

454 tested before dropped off. Open headers out the back and a snappy throttle is GREAT!

Another gem I hadn't seen there before

Friends playing Kings cup. Yes, the jersy says 'Beast Mode', the dude is 225 and holds me in highest regards for keeping up with him @ gym.

The chick laughing is the baby's mama, dude to the right is father, left is my best friend, guy in white a really good friend i've known 6+ years.

I didn't get home til 5 cuz Denny's is open and we had extra beer when we got back lol

Skydive:

My phone didn't get any of the in-air divers, or formations...

Purple jumpsuit lady, it was her Bday. Her son is on the fence, my gf is wearing her hat, and the mother in law of the Bday skydiving girl

Roll up them 'chutes

Texas Roadhouse:

Bday girl in center, my gf to the right and close, bday girl's mother in law on left.

Its an inside joke between my gf and bday girl that they are Gfs; the husband sat across the table and my gf exclaimed she was lucky to be between both her lovers

Outside Texas Roadhouse:

I love fast cars, but I like the old too

And I've been hired to paint rims for a friend

944 rim, paint stripped needing a polish to remove the oxidation on the machined lip

What its supposed to look like:

So I will turn over some money by painting rims before tooling on the supra.

I'm off to sort the collection in my garage to facilitate work, can't do anything with it so clustered