My garage was definitely not ready for any sort of real work, did not have an air compressor, and the garage was totally unfinished, uninsulated, and unheated!

I also wanted to come up with some sort of temporary paint booth as well as finishing the garage. Didn’t really know how to go about this, but here is what I came up with

I got ahold of a big squirrel cage fan from a house furnace, mounted in a box. I was going to use this to make a ventilation system for my booth. Exhausted to outside to get rid of fumes, mounted up in the attic to save space and to eliminate noise(tough to get it up there!! With 4, 6” ducts feeding the fan from inside of the planned booth area. 2 on the ceiling, and 2 from the bottom of the walls, this way I could get some sort of all around air flow.

Used furnace filters to stop overspray from making it outside. Fumes are one thing, since my neighbors know what I am doing and don’t mind, but I don’t want to be that guy that gets overspray on someone’s car!

I used thin foil backed foam insulation in two of the wall cavities, Plumbed the ducting into the tops, and then mounted furnace filters on the bottoms using the cavity as duct. It has worked incredible so far. Also had an oldschool metal caged light fixture that I decided to mounted at the top of the wall to use as an indicator lamp to tell me when the system is working since it’s so quiet inside the garage (Outside it isn’t so quiet with all that air flow!) Oh, also picked up an air compressor!

Here is an indicator of the size of the garage we are working with, it is 24x30. Now I needed to plan out a functional booth. Both to stop from making my garage a dusty mess, and for adequate ventilation of fumes when I get around to painting.

I think that what I came up with for the booth itself is pretty damn cool! Pretty proud of it

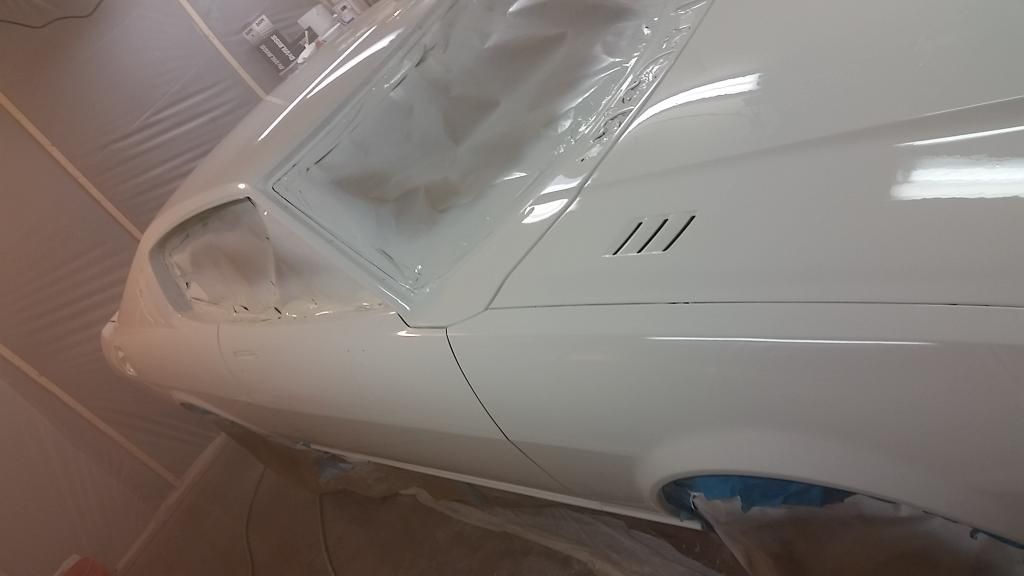

I used 4mil(or 6, don’t remember) plastic sheeting, tack strips, a 1x1, then some stick on zippers to make a door. Overall pretty cheap, maybe $90 total, and extremely effective. I wrapped the plastic around the tack strips and screwed it to the ceiling and walls. Then wrapped the 2x4 around the hanging excess on the floor. Now the cool part. I took some more tack strips that were the exact height of the roof, and bent them in-between the top and bottom pieces of wood. Did this because I wanted it to be removable, and to tension the plastic so it didn’t get sucked in when I turn on the powerful ventilation. I had a bunch of flourecent lights laying around, so I added another circuit and switch, and wired up a bunch of lights in the booth so I could see what I was doing!

So, now when I am finished, I will just remove the vertical stringers, roll the bottom 2x4,s up to the ceiling, and put a bungee cord around it and hold it all right up at the ceiling totally out of the way. Can just take it back down whenever I need to paint anything again.