<bought up to date for Joe>jetjock said:Lol. "One head bolt...two head bolts Yo sucka..."

BHG jOb

- Thread starter wchico15

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JustAnotherVictim

Supramania Contributor

87 n/a. Reused the stock bolts when I did the h.g. on mine as well. I would advice taking the head to the machine shop and having it checked and milled as necessary. Make sure you blow out all the bolt holes prior to putting the gaskets on. I torqued mine to 70 ft. lbs., and its held fine for almost 3 years now.

Just to mill it, around $40. To check it for cracks, clean it, valve job, etc., costs more. Manually cleaning the block should be fine, as long as the deck isn't severely pitted. I wouldn't take sandpaper to it, as its possible to create low spots. A scraper should get you by just fine. If you hit a stubborn bit of gasket, try soaking it with PB Blaster for about ten minutes, then scrape it again.

SupraSabre said:I know that they are very expensive for some one on a budget, be sure to put ARP head bolts or studs on your list! And clean out the block threads really good. :thumbup:

And throw your old ones away.

+2, I just did mine, hks head gasket with arp's...i ran into a problem with the re-torque, i stripped the 14th bolt and had to heli coil it, it worked but it took 2 weeks downtime so be careful

cuel said:Just to mill it, around $40. To check it for cracks, clean it, valve job, etc., costs more. Manually cleaning the block should be fine, as long as the deck isn't severely pitted. I wouldn't take sandpaper to it, as its possible to create low spots. A scraper should get you by just fine. If you hit a stubborn bit of gasket, try soaking it with PB Blaster for about ten minutes, then scrape it again.

Soft wire wheel and Carb cleaner does wonders

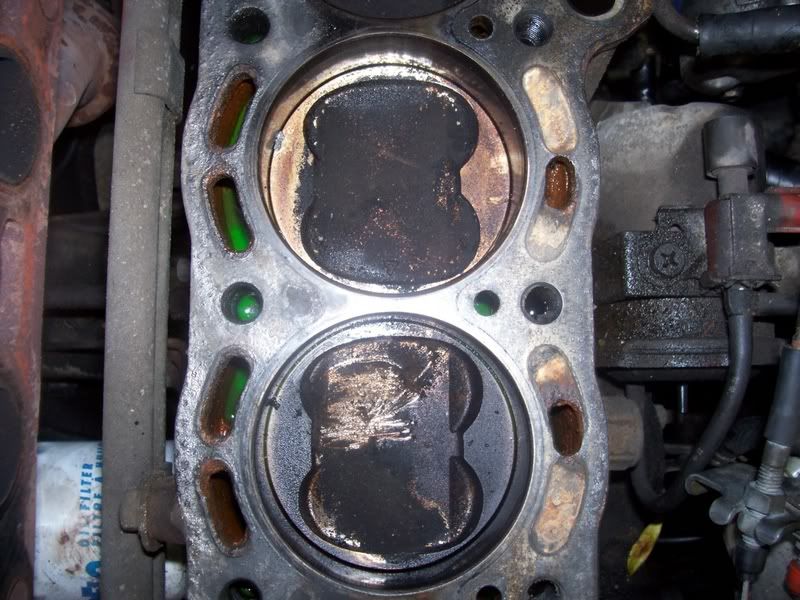

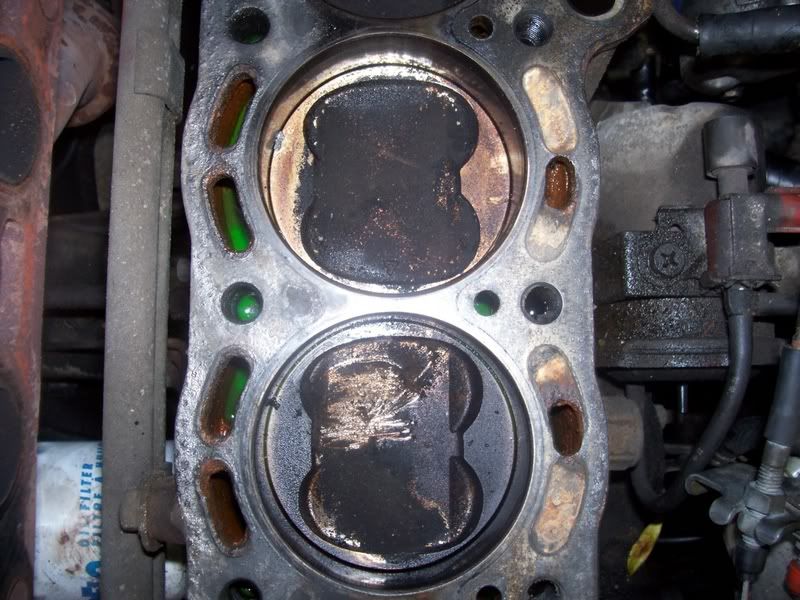

i've decided that im going to reuse the old headbolt,im on a strict budget and im going to be taking the advice from the SM experts/contributers. also should i put some sort of lube on the threads of the old bolts before putting them in again? im going to take the head to get milled and use the money i would of used on arp's to have it cleaned. as for the block im going to manually take off the old gasket material with a gasket scraper and if i run into stubborn parts i'll take your advice cuel. im also going to be using OEM headgasket that cost $98 from toyota. and FINALLY SOME PICS.

Last edited:

Only times I wouldn't reuse the headbolts are if I knew they've been overtorqued (if they have been there's a good chance the head is junk) or if the threads are erroded or if it's a high HP turbo build.

Would it not be a good idea to use new headbolts if you don't know the history of the motor? I know most people on here aren't the original owner so who is to say the previous owner didn't torque the shit out of it? If it was me, I would think this is a good place to spend the hundred dollars.

SB: The headbolts get a really bad rap when in reality they're quite good quality stock.

If a bolt has been pulled past it's TTY value you can usually see signs, as I said on a high HP build yep new hardware is essential but on an NA it's not really necessary (other than peace of mind).

If a bolt has been pulled past it's TTY value you can usually see signs, as I said on a high HP build yep new hardware is essential but on an NA it's not really necessary (other than peace of mind).

There are very few times when you would need to replace head bolts on a stock N/A build. Replacing them as a precaution is another story. When you pull the bolts out, clean them up with a wire brush and a little carb cleaner or such. Inspect the threads. If you see signs of pitting or deformation in them then definatley replace them.

I was under the impression headbolts were torqued to an amount that did infact cause mild yield or at least enough stress that they should not be unloaded and loaded again, maybe even beyond the original stress.

Although my motor has had 4 HG's and I'm not sure new Headbolts were used on any so I will not be risking using the old bolts.

Although my motor has had 4 HG's and I'm not sure new Headbolts were used on any so I will not be risking using the old bolts.

wchico15: A wire wheel in a drill would actually work pretty well for cleaning the block deck, just don't stay in one place. Keep constantly moving until its all clean. You should run a tap down the head bolt holes as well, to remove any corrosion that may be there. Blow out all the holes really well, and use a little motor oil on the bolts when reinstalling them.

suprarx7nut said:I was under the impression headbolts were torqued to an amount that did infact cause mild yield or at least enough stress that they should not be unloaded and loaded again, maybe even beyond the original stress.

Although my motor has had 4 HG's and I'm not sure new Headbolts were used on any so I will not be risking using the old bolts.

Thats what Ive read too, the stock head bolts are designed to be stretched when first used. Once they are stretched you shouldnt use them again.

I dont claim to be an expert on the bolts or materials, just repeating what Ive read many times which may very well be wrong. I know alot of people say shops will reuse the bolts all the time. Well, to me that means no thing, shops are going to do whats cheapest for them. If the bolts fail chances are they get your car back in the shop which is just more money for them.

Here's where the TSRM details installing the head. http://cygnusx1.net/Supra/Library/TSRM/MK3/manual.aspx?S=EM&P=55 I don't see where it says to use new bolts?

cuel said:Here's where the TSRM details installing the head. http://cygnusx1.net/Supra/Library/TSRM/MK3/manual.aspx?S=EM&P=55 I don't see where it says to use new bolts?

So, I take it you also torque the bolts down to the specs in the manual as well?

This will be a never ending issue, like I said Im no expert. I can just go by what Ive read, the bolts stretch and if they are stretched to the limit you shouldnt re-use them. How do you know if the bolt is at its limit if you dont know how many times its been used?