Update time... Just got home from the shop.

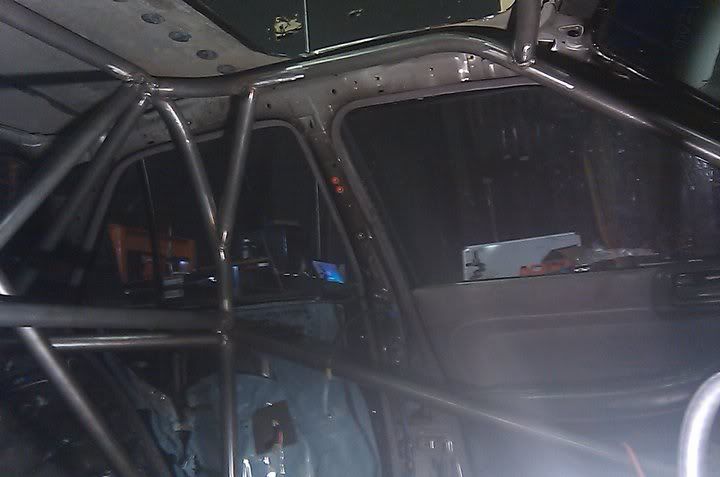

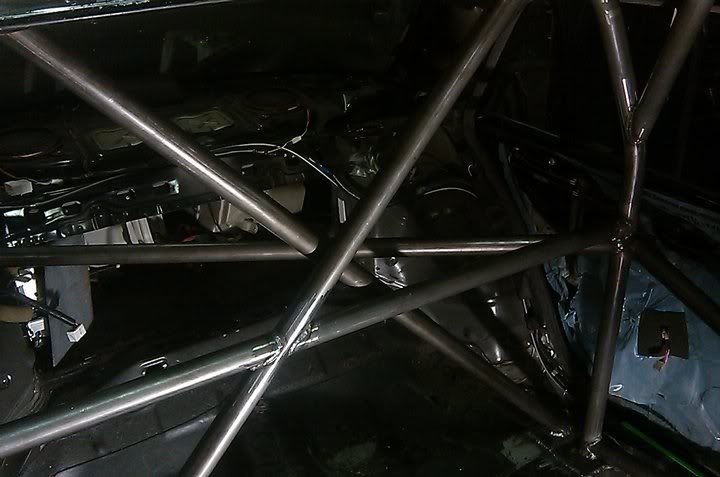

Bottom end rotating assembly is all together. Oil pump and oil pump driveshaft is installed. All Oil galley plugs and block offs are sealed and installed. Plan for tomorrow is pull apart the head, clean it, and re assemble. Double check lash so its ready to be installed. Going to clean up the Front cover and put it on followed by the head. Then Ill pull it off the stand and install the rear main seal housing and put it back on the stand to put the oil pan on. Slap the valve covers on and will pretty much be done with the long block.

Main bearing clearance .002

Rod bearing clearance .0025

Crank thrust clearance .006

Oil pump drive shaft bearing clearance .002

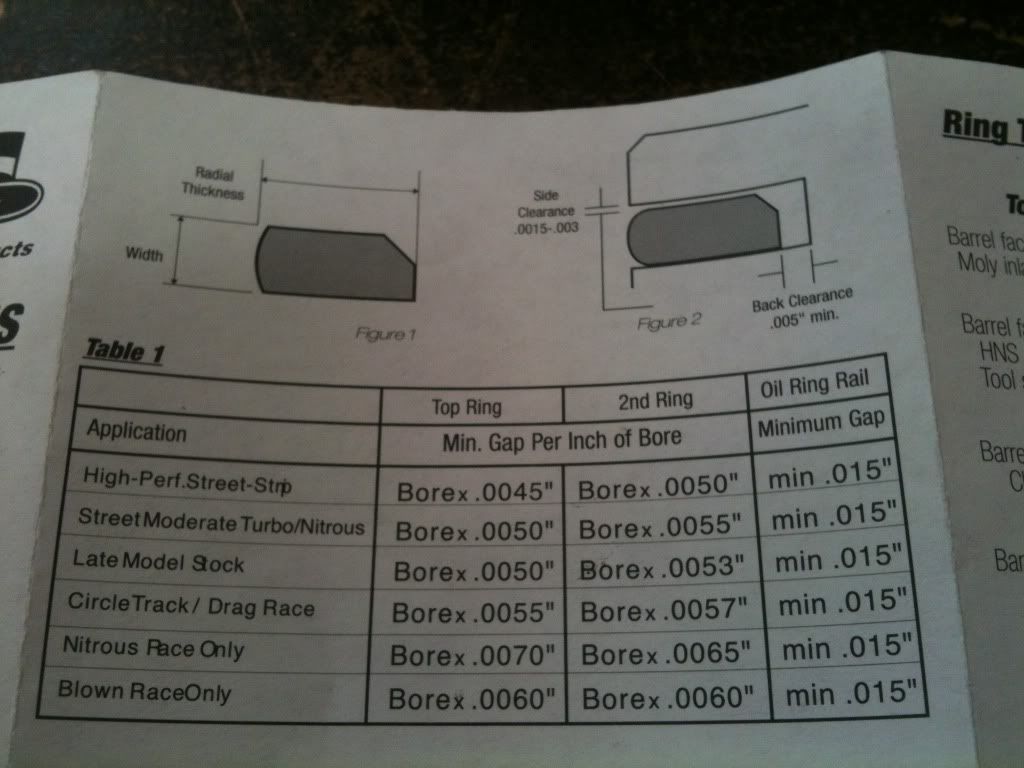

Oil Ring gap .018

2nd Ring gap .021

1st Ring gap .018

P2W Clearance .005

Piston to Deck Height .011 Positive

Piston to Deck Rock Height .022

Main Bolt @ 75 ft lbs (oil)

Rod Bolts @ 45ft lbs (ARP)

Continued tomorrow with Head clearances and Piston to valve ect.

Thanks,

Devin