1-2clutch-u;1244063 said:nice man makes me want to go back to school.

concept is easier than you think, its years of hands on experience that makes the cake.

Duane, where is this bolting to on the head?, been a while since i took that area apart.

1-2clutch-u;1244063 said:nice man makes me want to go back to school.

4U2QUIK;1244062 said:comparing a matsura to a haas is like comparing a mkiii supra to a ford escort.

lol, I personally like moriseiki's. They hold up better than anything else out there. but anyway nice work again.

1-2clutch-u;1244063 said:nice man makes me want to go back to school.

gaboonviper85;1244129 said:im gonna be straight with you...school is a waist if you are serious about wanting to learn to machine.....the best way for you to get a machining education is go be a shop bitch...you power a broom and then they start you on basic shit....machining can ONLY be done by hands on experience...no book will teach you the feel and let you listen to tools...you can listen to the way it sounds cutting and learn when a tool is getting worn just by its sound....books wont teach you that....

why pay for an education that you can get for free and infact be paid for it....and there is no good cnc programmer who doesnt know how to run a manual machine....in order to be a good programmer you need to know how to actually run a machine and know how shit feels while cutting.

machining school is a crock and a waste...just get a job at a machine shop for the best education.

again i machine for a living

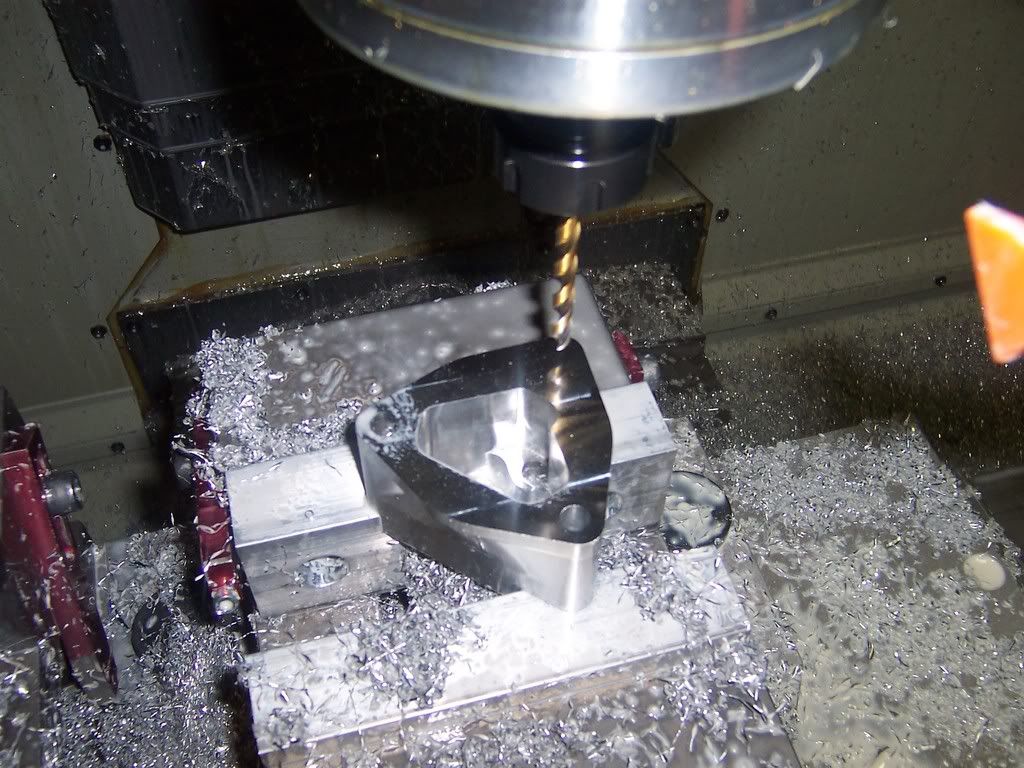

got_boosted;1244231 said:Looks good! If I had a 7M I'd buy one. You sure you don't want to produce these?

empera;1244255 said:i will hafta disagree with somethings but not all. If you get certified you will earn more money and it'll be easier to get a decent job.

Poodles;1244469 said:I see how the housing mounts to the head, and then the t-stat cover mounts to the housing, but how does the the actual fitting attach? I see the o-ring, maybe there are threads I'm not seeing?

I love seeing how stuff like this works...

gaboonviper85;1244548 said:I'd like to hear from an actual machinist on here becides me..

gaboonviper85;1244548 said:Maybe as a doctor, or a nurse, or even a mechanic but not in machining...no shop ever asked me for certifications or if I have a degree...all they ask is can you do the job...you get paid what you are worth and if you are not worth what your degree says you're worth you get fired! I've seen so many people fresh out of school who have no clue and they get fired in the first couple months...they days of senior tool maker cert are over....now it's if you do the job you get paid, if you scrap parts and simply suck you're fired!

I've worked in many shops and the only test I ever had to take was "can you read a mic?"...

Also I've only been turned down from 1 shop cause I didn't have a highschool diploma from the 7 I've worked at...also happens that it was a woman who was in charge of hiring...she never ran a machine in her life...only company ever to turn me down cause I didn't have a piece of paper...

School helps sure!!! But it's a major waste of money in the machining

industry as most shops want to teach you how "they" do things as every shop is diff.

Everyone I know never went to school or whatever...they all started from the bottom and worked there way up.

I'd like to hear from an actual machinist on here becides me..