So where's all the weight???

- Thread starter Wiisass

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I would say all the weight is the Rear Subframe. I took one of those out with my friend and we lifted it into his van and it was rediculously heavy. He's like yea and you wonder where all the weight is in these cars. Im like yea no shit. Jesus christ that shit was heavy as a bitch!!!! :aigo:

Here's a pic for shits and giggles. :biglaugh:

Here's a pic for shits and giggles. :biglaugh:

figgie;1042801 said:Hey Wiisass...

Weigh the fusebox inside of the cabin PLUS wiring to see what that rings up as

LMAO PDM justification at it's finest

fstlane88;1042641 said:I would love to see a tubular subframe for the Supra. Just the front would be awesome, along with the weight savings it would create so much more room to work.

The shop I work for sells Mustang complete tubular front end kits with the K-member, A-arms, and a coil over kit, for $700. I've bugged them about making one for the Supra but we're just too busy, and from my understanding it's take a bit of time to create something like that.

I think the front could be possible. I started thinking of all kinds of crazy suspension things I could do with it. But the design of both make it kind of difficult to do. And do have it designed right would take a lot of time. It's probably something I will work on and prototype but even if I get it done this season, it won't be ready for market for a little while.

Amontgomery;1042751 said:As far as motor choices go, and I know I am going to get crucified on this, wouldn't the

3SGTE be a more viable option for a handler. It would move the weight back quite a bit with propper motor mounts. The A80s in JGTC ran this motor in GT300 class with good results.

For killing weight in the doors, doesn't S2 make carbon doors for the A70? And I think I also heard that they are working out interior panels as well.

And for getting some weight out of the subframe some of the flat sections in the floor pans could be cut out and replaced by riveting and sealing aluminum or carbon fiber sheets in their stead. Chamfering holes in places will remove weight without sacrificing too much in the rigidity department.

For someone who knows how to work carbon fiber check out eFFeTT in the build thread section. He is making a full CF intake manifold for a twin turbo 7M.

Go in the Road Racing section on Supraforums and check out ideal98supra or something like that's Mk3 track car build thread. I'm really excited to see his car and how it all comes out. And I agree, a shorter in length motor, especially one with an aluminum block would go a long way in reducing front weight as well as overall weight.

Carbon doors are one of those things that I would only use with a good cage in the car. And at that point, you could just cut the door anyway. I'm still curious as to what a gutted door would weigh in comparison to the S2 carbon doors. But composites are always a good way to save weight, I just don't know if the more commonly available stuff is really taking advantage of current composite technology.

I don't know if there are any really good spots to start cutting out of the subframes. I mean it would be possible, but I think the whole thing is overbuilt and cutting and welding in new material just wouldn't be strong enough. I don't think there are any spots were material could be removed that would work with riveting in aluminum or bonding carbon, at least on the subframe. Just because the way the subframe is loaded and designed, it looks like it would be hard to cut much weight out of it without a redesign. But then again, I haven't looked too closely at it and might be able to find some spots.

7Mboost;1042757 said:Race cars on the street ftmfw. That is all.

I concur.

figgie;1042801 said:Hey Wiisass...

Weigh the fusebox inside of the cabin PLUS wiring to see what that rings up as

Almost a million pounds. I had the whole wiring harness from another car in a box and that thing weighed a decent amount. I would estimate 50-60lbs, but I have not actually measured it yet.

But the car will be getting a brand new wiring harness. I have some things I want to try and will probably be bugging you about some of it later on. But I just want something that will work and be simple, and not cost a million dollars. As much as I would like a super sweet harness, I'm going to have to settle on a super sweet harness on a budget. But I do want to use some through panel connectors if there are any cost effective ones.

TuRbOdReAmZ87;1042829 said:I would say all the weight is the Rear Subframe. I took one of those out with my friend and we lifted it into his van and it was rediculously heavy. He's like yea and you wonder where all the weight is in these cars. Im like yea no shit. Jesus christ that shit was heavy as a bitch!!!! :aigo:

Yeah, I posted earlier in the thread, with wheels and tires, it weighed about 400lbs. It's not all the weight, but it's a good bit. There should be some places to save some of that though.

This may be a question more for JJ but would it be possible to use aluminum wires in the harness. Or would there be too much resistence interfering with the functionality of the wires themselves. This is purely an academic question, as I don't know where to find aluminum wires of the correct guage to run in a automobile harness.

I have an idea about unibody lightening. I am assuming you have removed the paint from the bottom of the car. Find the key structural points and build bracing like an exoskeleton cage from rock crawling but instead of having the entire total of bracing made from steel have steel tabs and fittings with threaded areas and aluminum tubing threaded into the mounts. It would allow you to tune the chasis stiffness as well as allow you to remove greater portions of the mild steel body, especially in the flat bits like the floor panels and the area under the rear seats.

I don't know what you mean by any of that. But I think you have a weird obsession with aluminum.

And the car is getting a real cage. It doesn't need extra bracing.

IJ, sounds good to me.

And the car is getting a real cage. It doesn't need extra bracing.

IJ, sounds good to me.

Yeah, aluminum/carbon fiber, I get off to it.

No, J.K.

I wish I could post pics of what I am talking about. I can't explain things to save my life.

Well since your chasis is already stiff(no pun intended) you should have ample places to trim sheetmetal and replace it with lighter material.

No, J.K.

I wish I could post pics of what I am talking about. I can't explain things to save my life.

Well since your chasis is already stiff(no pun intended) you should have ample places to trim sheetmetal and replace it with lighter material.

Last edited:

Yeah, a pic would probably help. I think I get it, but I'm not sure. You're talking about braces between the frame rails and other points under the car?

And there is a lot of sheet metal that will be either totally removed or cut out, dimple died and welded back in or trimmed a little when the cage goes in.

And there is a lot of sheet metal that will be either totally removed or cut out, dimple died and welded back in or trimmed a little when the cage goes in.

Exactly. Like a mini cage for the bottom of the car, but instead of completing the cage out of one material, build the corners out of steel(so it can be welded to the cage, unibody, frame, ect) and thread it in such a way so that aluminum tubing can be threaded into the gaps in between the corners.

Its hard to explain it in writing. I'll try to do it on MS paint to explain better.

Its hard to explain it in writing. I'll try to do it on MS paint to explain better.

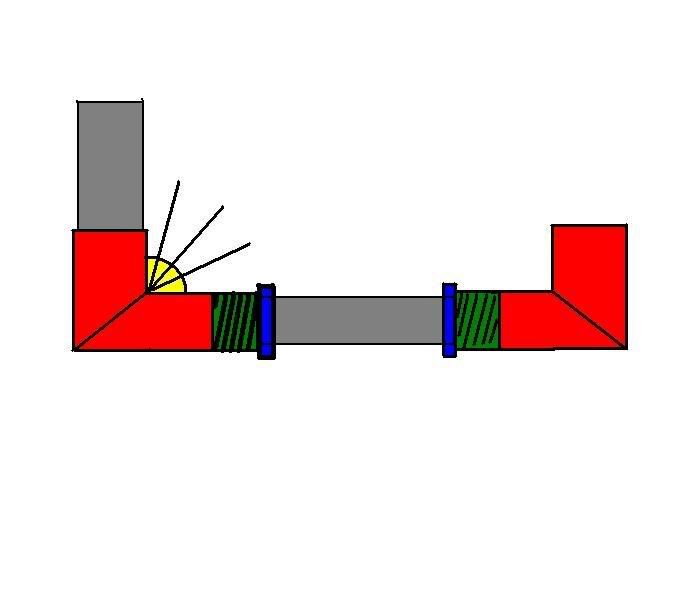

Red is steel

Grey is Aluminum

Green is threading

Blue is locking nuts

Yellow shows the point where angles can be changed to fit different parts of the chasis.

I am sorry it is kind of rough. I hope you can get an idea of what I am talking about as far as the cage's construction is concerned. The steel pieces can be welded to the unibody or cage. This would be primarily for bracing for the floor and other areas that would be patched with carbon fiber or aluminum so the floor doesnt fall through under pressure, and still retains the stock steel floors rigidity.

If you're serious enough to spend the money, aluminum bolts. They are ridiculously lighter. The new BMWs use them because they have magnesium blocks, and steel would corrode instantly. In fact, some are one time use.

Two disadvantages are huge price and non-ferrous. I like being able to pick bolts and such up with a magnet personally.

Two disadvantages are huge price and non-ferrous. I like being able to pick bolts and such up with a magnet personally.

Racing car battery mine weighs in at 11.4 lbs as apposed to 38 lbs for a regular one.

I'm in the middle of removing stuff from my car (don't worry it was pretty much a basket case so its not like I'm fucking up a good car more rescuing one from a premature death) and just by doing simple stuff I have calculated I can save 140 kg (308 lbs) so by going to the lengths you are sub 3000 lbs shouldn't be to hard.

I'm in the middle of removing stuff from my car (don't worry it was pretty much a basket case so its not like I'm fucking up a good car more rescuing one from a premature death) and just by doing simple stuff I have calculated I can save 140 kg (308 lbs) so by going to the lengths you are sub 3000 lbs shouldn't be to hard.

Amontgomery;1042966 said:Red is steel

Grey is Aluminum

Green is threading

Blue is locking nuts

Yellow shows the point where angles can be changed to fit different parts of the chasis.

I am sorry it is kind of rough. I hope you can get an idea of what I am talking about as far as the cage's construction is concerned. The steel pieces can be welded to the unibody or cage. This would be primarily for bracing for the floor and other areas that would be patched with carbon fiber or aluminum so the floor doesnt fall through under pressure, and still retains the stock steel floors rigidity.

That's kind of what I thought you meant. But would it go under the car or inside the car? I really don't think it's going to support things the way you're thinking unless I'm still looking at it wrong. But cutting out the floors isn't really part of the plan just yet. I don't think it's needed to get to my target weight. There are a lot of other spots on the chassis that could be trimmed of some excess weight though. And I think that system could end up adding more weight than it saves.

Orion ZyGarian;1043136 said:If you're serious enough to spend the money, aluminum bolts. They are ridiculously lighter. The new BMWs use them because they have magnesium blocks, and steel would corrode instantly. In fact, some are one time use.

Two disadvantages are huge price and non-ferrous. I like being able to pick bolts and such up with a magnet personally.

I don't think that is needed either. Or I just don't feel like taking it that far in terms or time and money on saving a little weight. And the things that don't need as many bolts, don't have as many.

Down but not out;1043198 said:Racing car battery mine weighs in at 11.4 lbs as apposed to 38 lbs for a regular one.

I'm in the middle of removing stuff from my car (don't worry it was pretty much a basket case so its not like I'm fucking up a good car more rescuing one from a premature death) and just by doing simple stuff I have calculated I can save 140 kg (308 lbs) so by going to the lengths you are sub 3000 lbs shouldn't be to hard.

A lighter battery is a good way to save a couple pounds. I haven't decided what I'm going to run yet. I want to run one of the smaller Odyssey batteries as long as it will keep working for a little while. I like the reliability of the Optima that I had in the car last season, so we'll see.

And sub3000 was already done. I'm shooting for a little bit lighter than that and with a full cage in the car.

IJ.;1042869 said:Tim: I have the heaviest Mk3 pretty well covered you may proceed with the lightest

We will see about that!

It would go under the car and only where needed. And when floor pans would be cut a lip would be left and holes would be drilled in it to run the rivets through.

I could see that the ends made of steel would probably be too thick and add weight and the aluminum tubing would end up being thick as well. It would only be truely benificial if large sections of flooring could be removed and replaced with extremely light weight sheets of carbon fiber. But it would be way to costly to do it correctly as you don't want to pay for large sections of dry carbon.

I could see that the ends made of steel would probably be too thick and add weight and the aluminum tubing would end up being thick as well. It would only be truely benificial if large sections of flooring could be removed and replaced with extremely light weight sheets of carbon fiber. But it would be way to costly to do it correctly as you don't want to pay for large sections of dry carbon.