Ridiculous 1000HP 7M Street MK3 Build

- Thread starter NegativeGeForce

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IJ.;1979215 said:How flat are the covers after that?

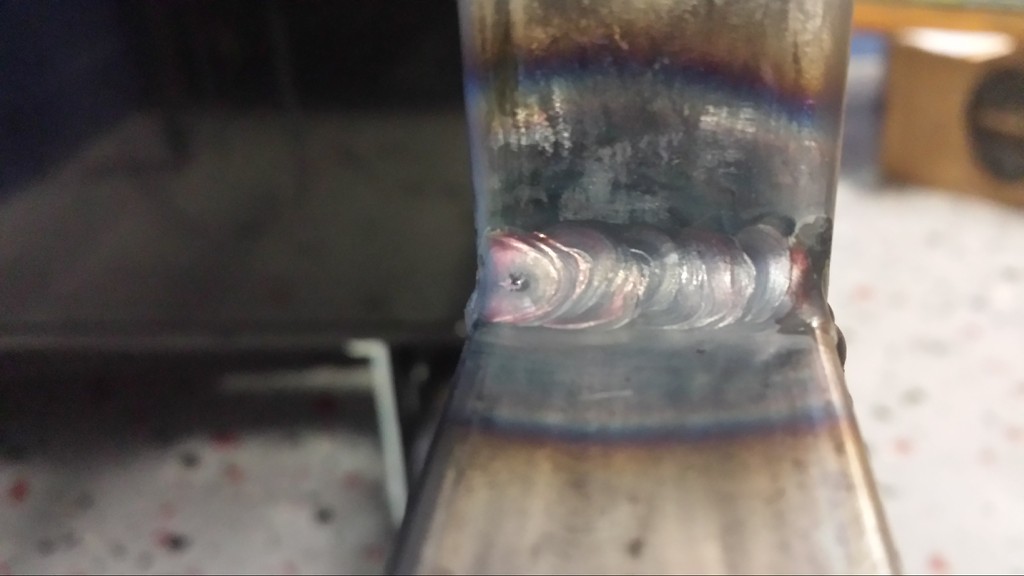

I actually bolted the covers down to the head while doing the welding to avoid warping. They are straight as before I did the mods.

LOL I never had any luck welding on the stock covers no matter what I tried.....

Always warped even when bolted down..

Always warped even when bolted down..

^ it's cause your welds most likly had penetration lol

or you never stepped your welding from side to side

or you never stepped your welding from side to side

bolting it down also acts as a heat sink. tig will put a lot more heat into the covers than mig.

I also tried to alternate from cover to cover when I did a weld so I didn't pour tons of heat into a single cover even though I probably spent way too much time on each weld. I played around with two types of tungsten and the thoriated ended up making much cleaner welds on the cast aluminum...the ceriated created alot of black soot all over the place that I had to go back over and clean up. I don't have a straight edge but the covers were rocking back and forth about 1mm on the head prior to the project...they are rocking the same amount now after. Not sure if the junk head i have is just warped to hell or the valve covers, lol.

Either way they actually turned out alot better than i expected. I was thinking id have to write these covers off since I haven't done alum welding before, but they turned out really good. I just have to hit it with a belt sander and smooth out the corners with sand rolls. I also want to tap the covers for -10 an fittings (will see tons of boost, need to use clown size lines to catch catch) remove the baffles to clean everything under them and tap the bosses to make the baffles removable then it's off to powder coat along with alot of other parts.

Either way they actually turned out alot better than i expected. I was thinking id have to write these covers off since I haven't done alum welding before, but they turned out really good. I just have to hit it with a belt sander and smooth out the corners with sand rolls. I also want to tap the covers for -10 an fittings (will see tons of boost, need to use clown size lines to catch catch) remove the baffles to clean everything under them and tap the bosses to make the baffles removable then it's off to powder coat along with alot of other parts.

Last edited:

For fun try welding 2 pop cans together took me abit but I did it

some what fun too

I have a set of n/a covers that I want to cap then mill in the slots so they look stock

but I still don't want to try it yet since i will have to use thicker plate on the top

my idea to stop warping is to clamp the cover down over a spacer so when it does pull it goes straight

this is what mine does it's basic but does not have all the neat settings yours has

some what fun too

I have a set of n/a covers that I want to cap then mill in the slots so they look stock

but I still don't want to try it yet since i will have to use thicker plate on the top

my idea to stop warping is to clamp the cover down over a spacer so when it does pull it goes straight

this is what mine does it's basic but does not have all the neat settings yours has

Last edited:

IJ, you were right. After the covers cooled they bowed like 5mm.

I stuck a shim in the middle between the head and covers and bolted down both ends to bend them back then stuck the entire head (junk head) in a gas BBQ at 500 degrees for an hr. The valve covers are flat now

I stuck a shim in the middle between the head and covers and bolted down both ends to bend them back then stuck the entire head (junk head) in a gas BBQ at 500 degrees for an hr. The valve covers are flat now

LOL nice save!NegativeGeForce;1979753 said:IJ, you were right. After the covers cooled they bowed like 5mm.

I stuck a shim in the middle between the head and covers and bolted down both ends to bend them back then stuck the entire head (junk head) in a gas BBQ at 500 degrees for an hr. The valve covers are flat now

Still waiting for my J&E asymmetrical pistons so i can get the short block done.

Got my shadow grey dash and misc interior stuff today.

Got my caswell zinc plating kit. Yes, im gonna replate all the toyota hardware with zinc and use the yellow chromate to replicate cad plating look.

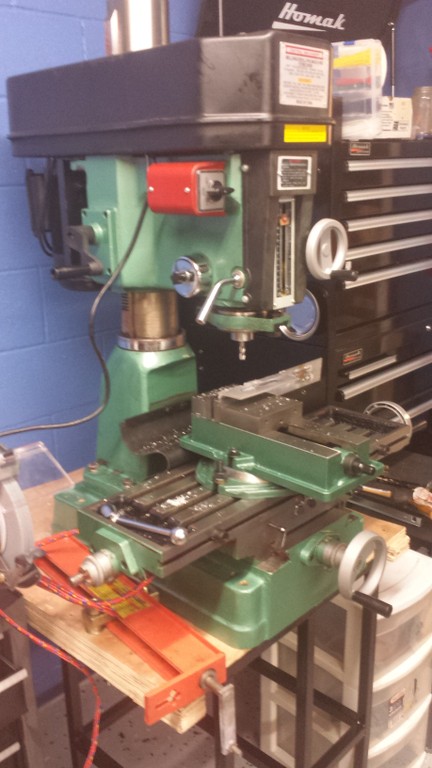

Got my mill. Gonna try to learn how to be cool like the other machinists here like Duane Stephens and Albert Meade.

Got building materials for a mill table that im gonna weld up this weekend.

First contract job...fixed a c6 vette radiator support for my buddy.

It's coming along...

Got my shadow grey dash and misc interior stuff today.

Got my caswell zinc plating kit. Yes, im gonna replate all the toyota hardware with zinc and use the yellow chromate to replicate cad plating look.

Got my mill. Gonna try to learn how to be cool like the other machinists here like Duane Stephens and Albert Meade.

Got building materials for a mill table that im gonna weld up this weekend.

First contract job...fixed a c6 vette radiator support for my buddy.

It's coming along...

I know this post is a year old, but did you ever try a heat relief with an oxy torch after welding, just to heat the aluminum all up to relieve the stress from welding?IJ.;1979223 said:LOL I never had any luck welding on the stock covers no matter what I tried.....

Always warped even when bolted down..

Yeah I did Sean, they had a memory and pulled back again after cooling...funky_monkey58;1983965 said:I know this post is a year old, but did you ever try a heat relief with an oxy torch after welding, just to heat the aluminum all up to relieve the stress from welding?

The gas BBQ @ 500 deg trick does infact work...straightened out my covers. They are still straight after cooling.

I remember when we used to chat every day! It's been a long time nice to see you doing what appears to be very well!

hvyman;1984077 said:So how is your tig holding up so far?

It's holding up really well. I recently made a stand for the mill using the tig and 1" square tubing. Went through 3 bottles so far (80 cu ft tank) welding random stuff.

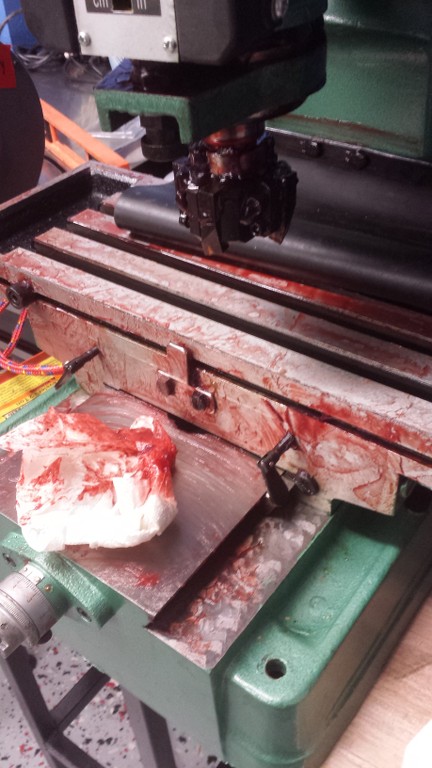

blood everywhere...ahh!!!

SupraOfDoom;1984075 said:I remember when we used to chat every day! It's been a long time nice to see you doing what appears to be very well!

Hey thanks, yeah I've been talking a long time about building something sick, time to do it finally, lol!

Found out it gets expensive pretty quick. I spent as much on tools as parts so far.

I need to dump like 12 grand more into it for the car to be where I want it.

When are you gonna finish your car?

NegativeGeForce;1984092 said:Hey thanks, yeah I've been talking a long time about building something sick, time to do it finally, lol!

Found out it gets expensive pretty quick. I spent as much on tools as parts so far.

I need to dump like 12 grand more into it for the car to be where I want it.

When are you gonna finish your car?

who knows. oh well.

DeMoN2318;1984413 said:Is that really blood all over the mill?

Lol no it was the packing grease.

Sent from my SPH-L720 using Tapatalk