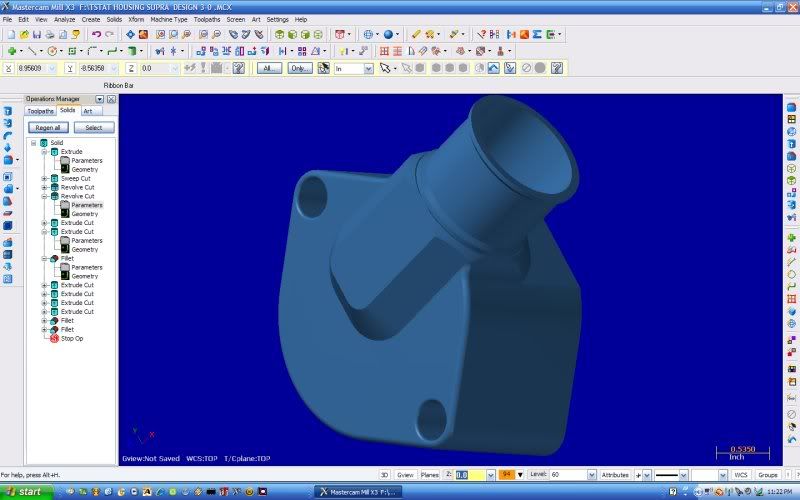

Project: CNC Machined thermostat housing

- Thread starter 4U2QUIK

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

odd i offered the same thing but no one really wanted one shrugs

the only down fall was for people with bigger rad's with stock shrouds very stupid close fit

down fall 2 the temp sensor location is useless spot since the thermostat is infront of it

the only perk to this is if you have adjustable cam gears and want to ajust them and still keep the stock look and pretty ?

the only down fall was for people with bigger rad's with stock shrouds very stupid close fit

down fall 2 the temp sensor location is useless spot since the thermostat is infront of it

the only perk to this is if you have adjustable cam gears and want to ajust them and still keep the stock look and pretty ?

Last edited:

4U2QUIK;1306616 said:I'm not sure where you're asking for the counterbore to be. But if you mean c-bore the bolt holes, I would need More clearance unless I included SHCS's Which would once again Drive up the price either way.

LOL Drive up price? Dude, it will take less than 5 mins to do that. Counter bore the holes that you attach the housing. Then you can use nice, clean, socket head caps screws and keep everything flush.

Duane

nope, denied...NTRA08;1309731 said:How about a pic of the inside

IJ.;1309647 said:

SURUKO;1309729 said:#2 is looking nicer ......

Doward;1309798 said:I like #2 as well.

ok... sounds like the 2's have it.GC89;1309878 said:

I guess I'll have the prototype sometime in the next week or so. I might be kind of hard to find the time while I'm boxing up all my stuff for the big move.

nah, I'll engrave 7m sux on it instead. j/kDoward;1309880 said:As long as I can still get 7M engraved on the raised portion

actually I want to use the laser engraver to do the engraving, I can pretty much take any b/w image and engrave it. I personally am going to put the image of a boobie on mine just for IJ.

5 minutes of production time = $12.50 being added to the final price.upgradedsupra;1309951 said:LOL Drive up price? Dude, it will take less than 5 mins to do that. Counter bore the holes that you attach the housing. Then you can use nice, clean, socket head caps screws and keep everything flush.Yes you would need more clearance but not much and I am sure it will still clear. Just a thought and that's what I would do if I made it.

Duane

Soo ,when it comes to production time 5 minutes is a lot considering the whole part will take between 20-30+ minutes to produce one part on the cnc.

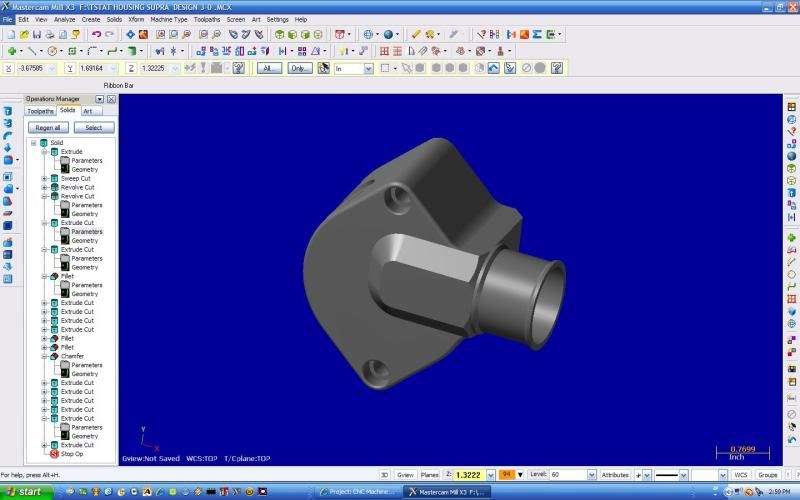

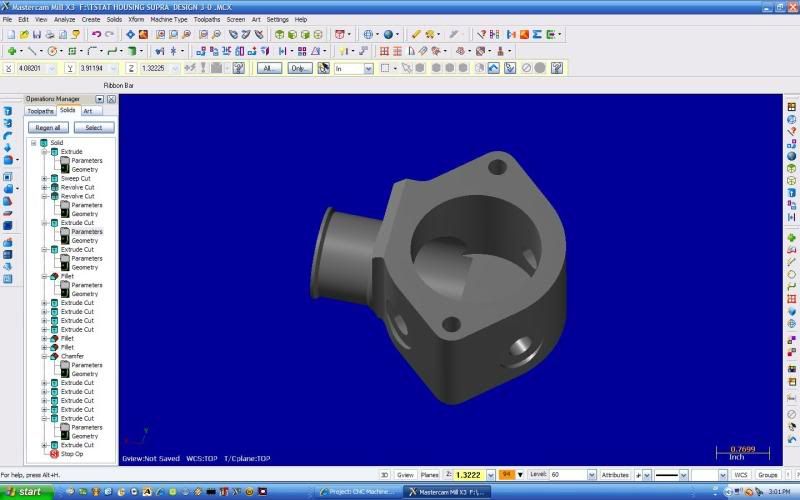

But anyhow, I succumbed to the idea, and if you look closely the new design is counterbored for SHCS.

4U2QUIK;1310014 said:5 minutes of production time = $12.50 being added to the final price.

Soo ,when it comes to production time 5 minutes is a lot considering the whole part will take between 20-30+ minutes to produce one part on the cnc.

But anyhow, I succumbed to the idea, and if you look closely the new design is counterbored for SHCS.

I was being sarcastic. It would literally take a couple of seconds to do them and looks cleaner. You wanted feedback, you have it.

Duane

Well, if anyone was wondering.... Yes, I'm still working on these. But I've been having problems finding a shop other than the one I work at that's reliable. So Tomarrow I'm going to be talking to the guys at billet balls (They make billet shifter knobs) about making them for me.

people suck....

but anyway, I was thinking about getting back to these. anyone still interested?

but anyway, I was thinking about getting back to these. anyone still interested?

Trying to sell CNC parts can be very trying

I see alot of hatin on the stock water neck and thermostat housing. You can also use the JDM one, which only has 2 instead of 3 fittings on it, and if you use a file, some TLC and some more time ant TLC again, you can make the water neck and thermostat housing look OK, as per below.

I was toying with getting a CNC thermostat cover made here, so I am very interested to see how your second design pans out

I see alot of hatin on the stock water neck and thermostat housing. You can also use the JDM one, which only has 2 instead of 3 fittings on it, and if you use a file, some TLC and some more time ant TLC again, you can make the water neck and thermostat housing look OK, as per below.

I was toying with getting a CNC thermostat cover made here, so I am very interested to see how your second design pans out

HKS_TRD;1458212 said:Trying to sell CNC parts can be very trying

I see alot of hatin on the stock water neck and thermostat housing. You can also use the JDM one, which only has 2 instead of 3 fittings on it, and if you use a file, some TLC and some more time ant TLC again, you can make the water neck and thermostat housing look OK, as per below.

I was toying with getting a CNC thermostat cover made here, so I am very interested to see how your second design pans out

That looks badass Dan, now to add his water neck cnc part to it and perfect! Of course, polish it, too.

Duane

For the OP, the parts are hard to sell because many don't want to pay what it is worth, and, CNC parts are not cheap to make.