Ok Well to start off todays work I got some parts in the mail. Thats always fun. They included a new oil pressure sending unit, battery tie down bracket, ARP flywheel bolts, and i'm guessing OEM replacement pressure plate bolts.

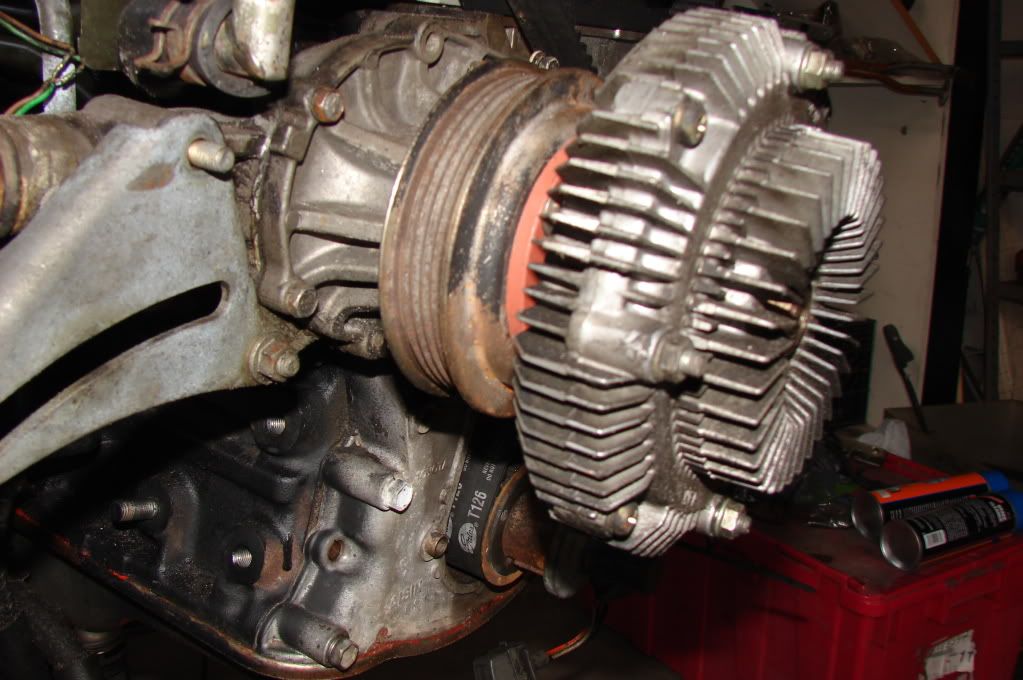

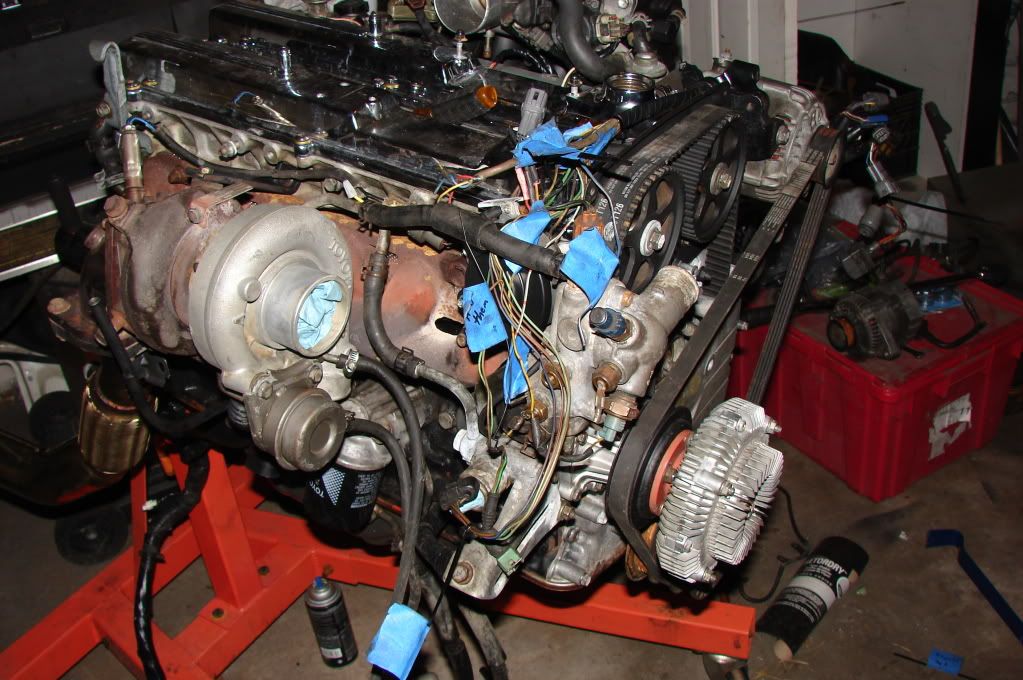

After I got done with a late Christmas I got to the motor. I started by repainting the following. And starting to put the wiring back on.

1.Upper intake plenum

2.Fuel bracket

3.3000 pipe

4.Motor mounting brackets

5.Something else that I probably forgot about.

Painted mounts

Upper plenum repainted,you can also see the wiring mess.

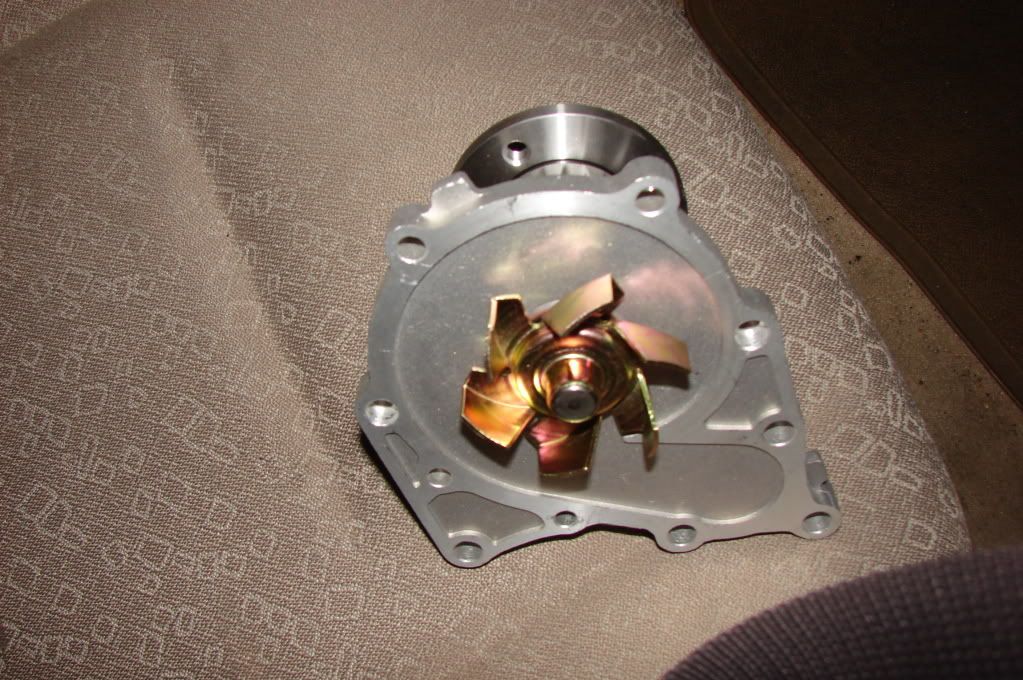

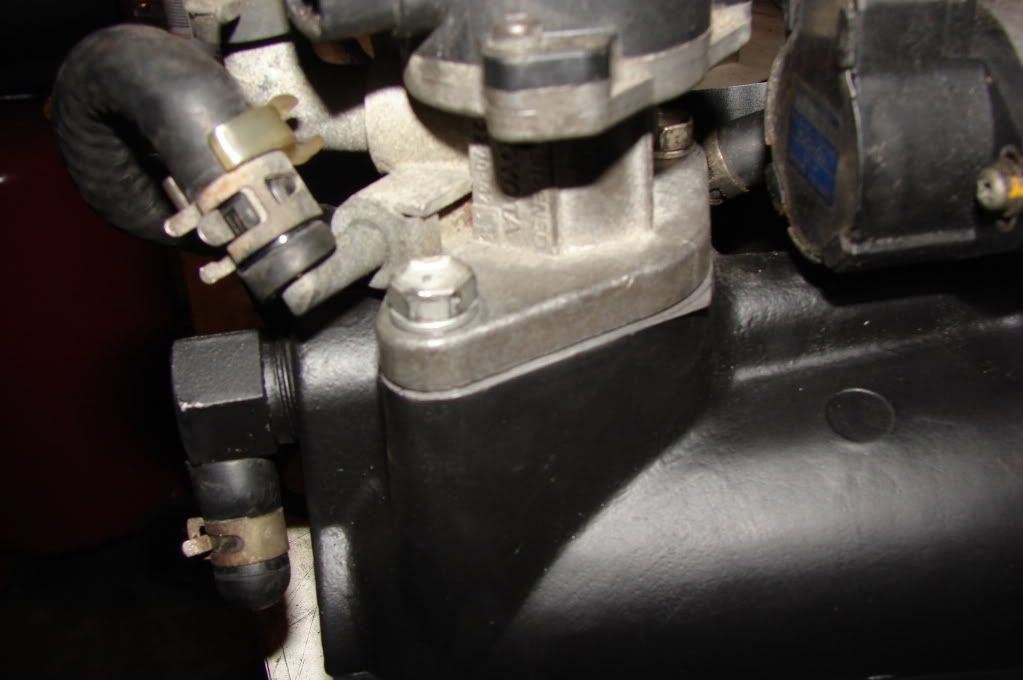

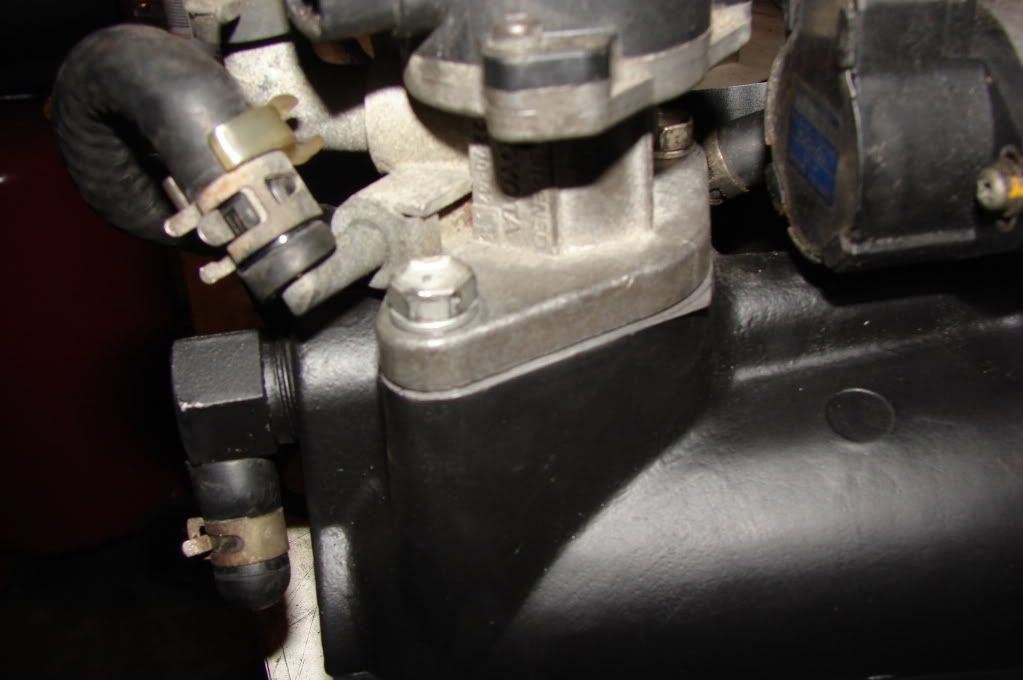

Installed a new oil pressure sending unit

Dirty cover that I later cleaned lol

My old oil pressure sending unit that still probably works, it just has a bunch of oil and paint on it.

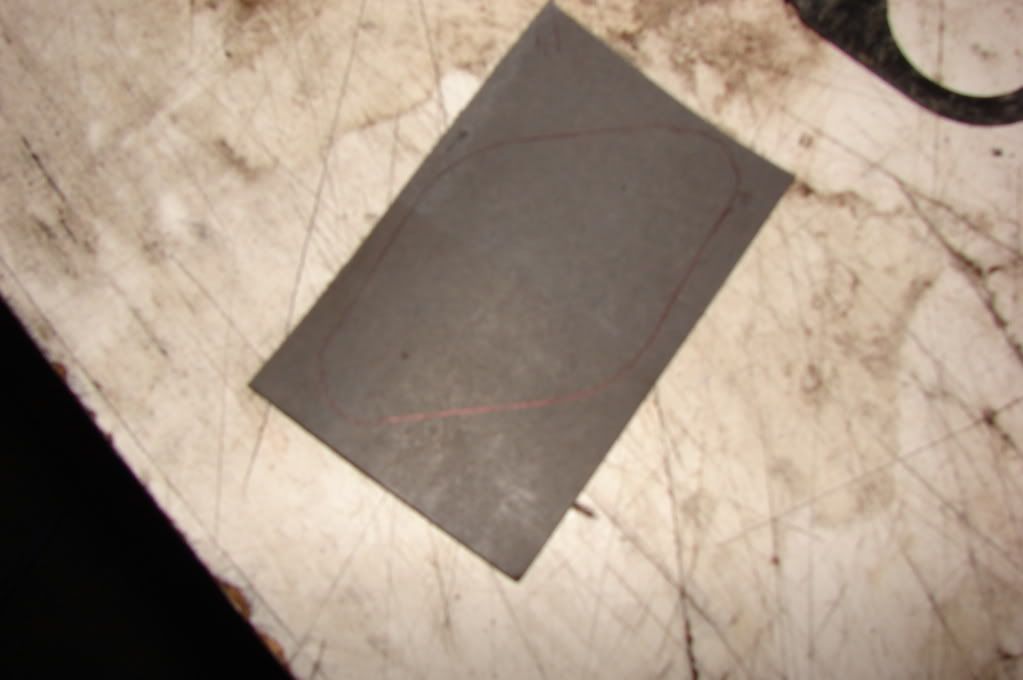

So I messed up the gasket on the upper plenum to some valve I want to say its the IAC valve but i'm not sure. So I had to make my own being that there wasn't a replacement one in the kit I bought. It turned out pretty easy to cut and make holes in it. I used a 1-hole paper hole puncher lol. But hey it worked.

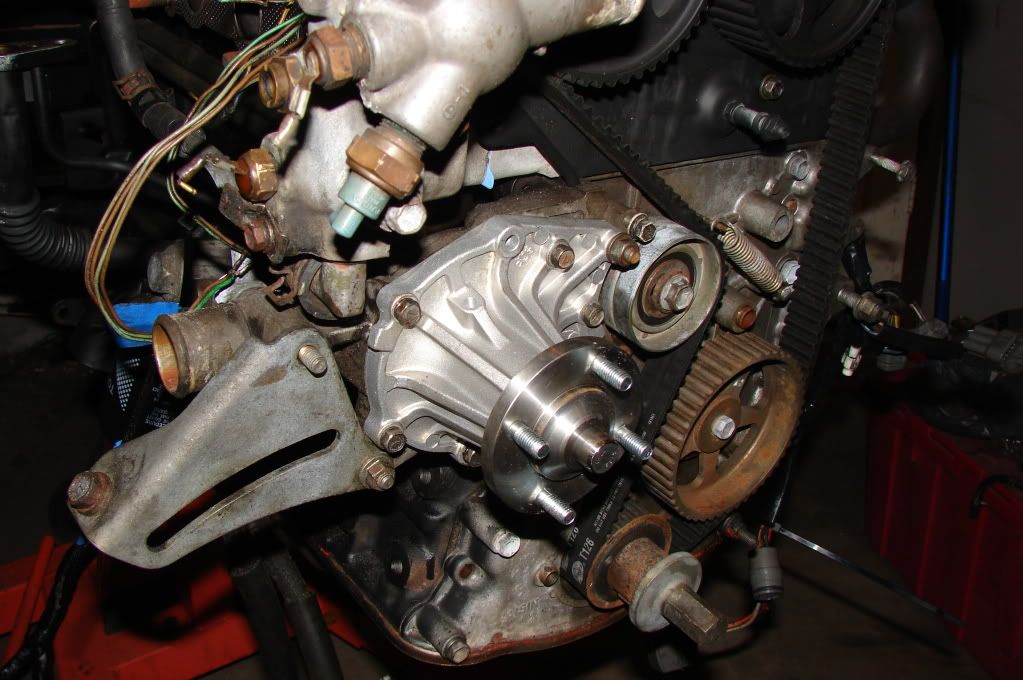

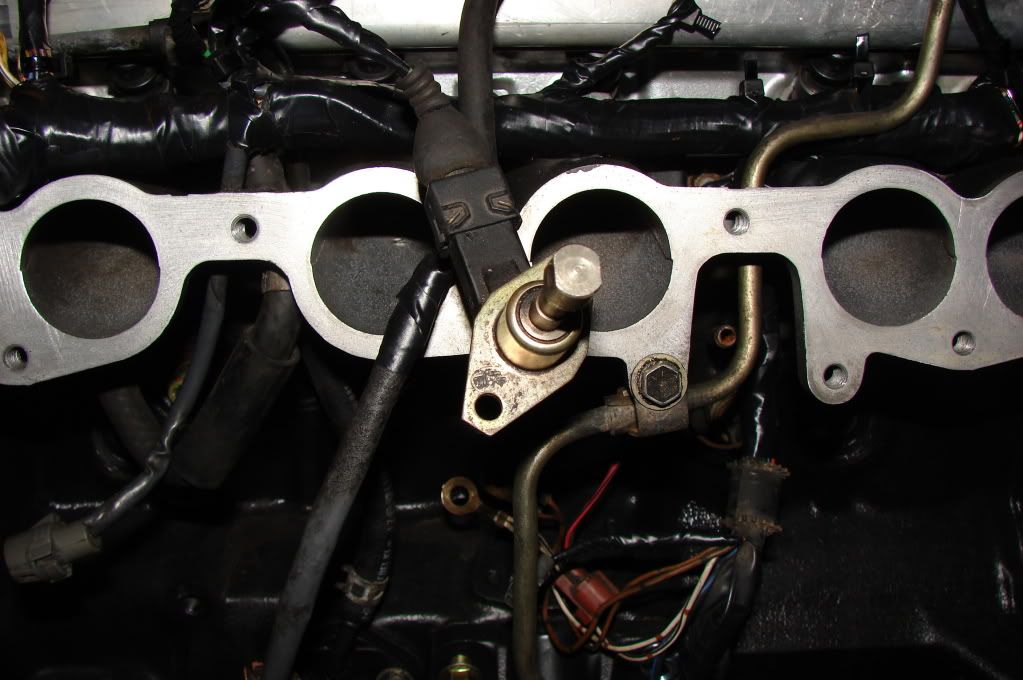

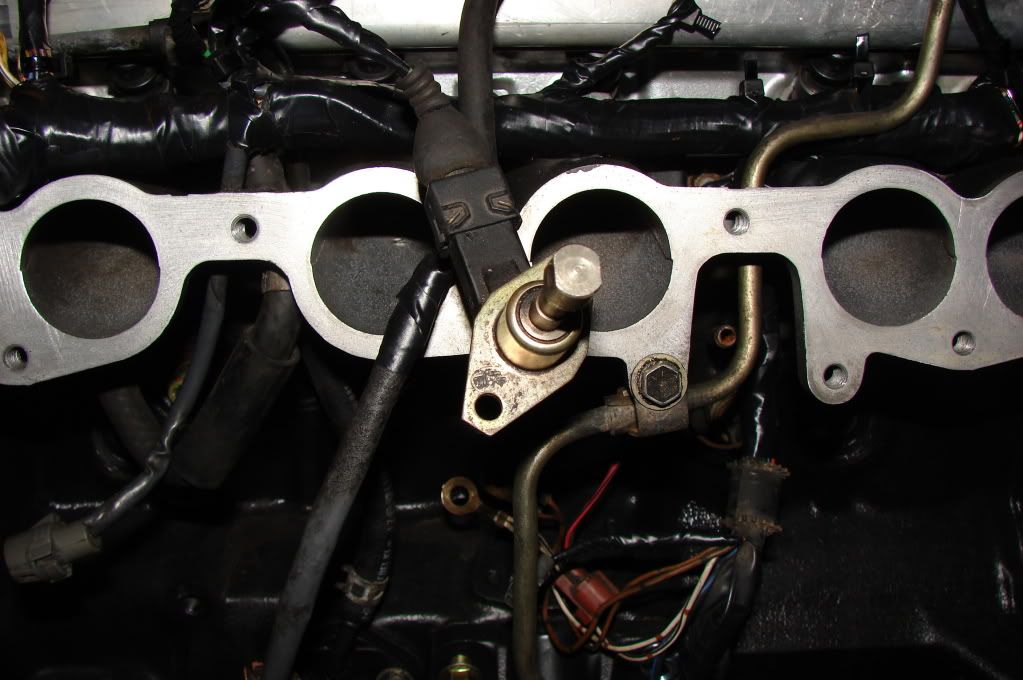

I had to remove the upper intake to run the knock sensor wires. People don't kid when they say its easier to get to these things when the motor is out of the car.

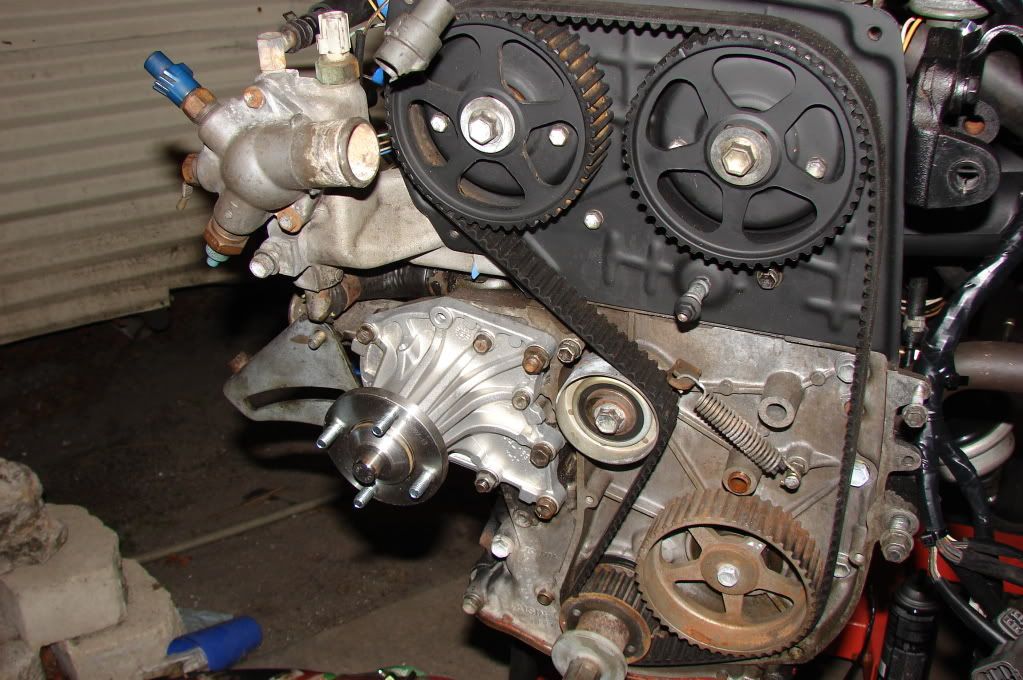

Close up of the lower intake plenums

Then took the valve covers off cause i'm about ready to re-torque the head down to 85lbs on the stock own replacement gasket. 85lbs, is a good mark to hit correct?

After I got done with a late Christmas I got to the motor. I started by repainting the following. And starting to put the wiring back on.

1.Upper intake plenum

2.Fuel bracket

3.3000 pipe

4.Motor mounting brackets

5.Something else that I probably forgot about.

Painted mounts

Upper plenum repainted,you can also see the wiring mess.

Installed a new oil pressure sending unit

Dirty cover that I later cleaned lol

My old oil pressure sending unit that still probably works, it just has a bunch of oil and paint on it.

So I messed up the gasket on the upper plenum to some valve I want to say its the IAC valve but i'm not sure. So I had to make my own being that there wasn't a replacement one in the kit I bought. It turned out pretty easy to cut and make holes in it. I used a 1-hole paper hole puncher lol. But hey it worked.

I had to remove the upper intake to run the knock sensor wires. People don't kid when they say its easier to get to these things when the motor is out of the car.

Close up of the lower intake plenums

Then took the valve covers off cause i'm about ready to re-torque the head down to 85lbs on the stock own replacement gasket. 85lbs, is a good mark to hit correct?