So I got my boost controller working last week and after a couple 22psi pulls I parked my car at my buddy's shop to cool down. My buddy then decided to back up a truck that has BHG and proceeds to rev and dump BHG smoke all over my supra. I quickly jumped in my car to roll up the windows and out of instinct started my car. Since it was started I figured I would antilag scaring him to stop.

The car immediately died as I started antilaging. I proceeded to try to start the car back up but it sounded like I had a dead piston. Now I'm like "great! The 22psi pulls melted a piston"

I then noticed my cam bolt wasn't turning when trying to start clear timing cover FTW)

clear timing cover FTW)

http://youtu.be/sFZcCyBFO4M

I took the cams out and down to my shop for repair. Here is what I found:

Exhaust cam threads stripped out and dowel pin was sheared right off

Looks like the threads of bolt were only engaged 3-4 threads deep. Out of the full 1" deep threads on the cam. I compared the HKS cam gear with a stock one and found out the HKS cam gear is twice as thick as the stock gear.

The dowel pin was only sticking .075 into the Hks cam gear where as the stock cam gear the dowel would sit flush with the stock gear.

So I decided to make a dowel pin out of 4340 that is longer so that it would sit flush with the HKS cam gear:

I put the cams into my machine and drilled them out and tapped them to 1/2-20 since the pitch is off .001. I then got a longer bolt that would engage all of the threads before bottoming out.

Thinking I solved the issue and what caused it was insufficient threads/short dowels/over tightened bolt. Boy was I wrong

After reinstalling everything, when I would go turn the motor over manually the motor would bind up. I for sure though I had bent a valve with the BC 272s

After poking around I noticed something strange on my exhaust shim/bucket in cylinder #4

Well I spit a shim! That's what caused the threads to strip and dowel to shear.

After doing some research the cause of me spitting a shim was in fact the antilag. The backfires could backfeed onto the exhaust valves relaxing the tension in the spring. If the timing is right, bye bye shim.

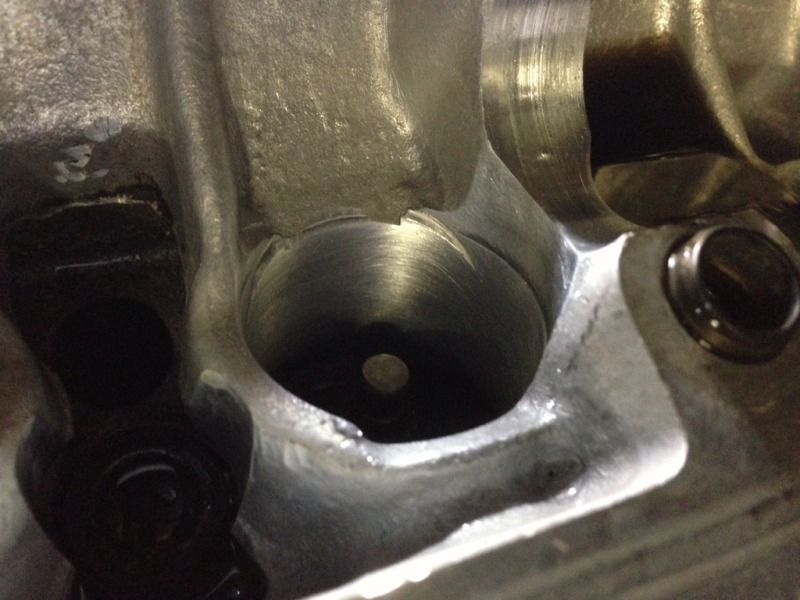

Carnage:

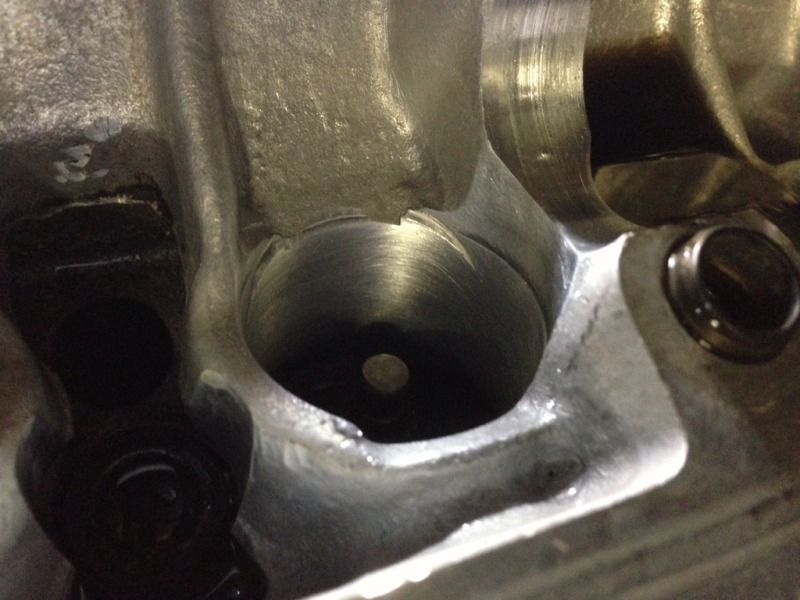

The bucket wouldn't come out so a nut was welded to it onto a slide hammer. Came right out

Cleaned back up:

1zz shimless buckets are in there way now

Discuss

The car immediately died as I started antilaging. I proceeded to try to start the car back up but it sounded like I had a dead piston. Now I'm like "great! The 22psi pulls melted a piston"

I then noticed my cam bolt wasn't turning when trying to start

http://youtu.be/sFZcCyBFO4M

I took the cams out and down to my shop for repair. Here is what I found:

Exhaust cam threads stripped out and dowel pin was sheared right off

Looks like the threads of bolt were only engaged 3-4 threads deep. Out of the full 1" deep threads on the cam. I compared the HKS cam gear with a stock one and found out the HKS cam gear is twice as thick as the stock gear.

The dowel pin was only sticking .075 into the Hks cam gear where as the stock cam gear the dowel would sit flush with the stock gear.

So I decided to make a dowel pin out of 4340 that is longer so that it would sit flush with the HKS cam gear:

I put the cams into my machine and drilled them out and tapped them to 1/2-20 since the pitch is off .001. I then got a longer bolt that would engage all of the threads before bottoming out.

Thinking I solved the issue and what caused it was insufficient threads/short dowels/over tightened bolt. Boy was I wrong

After reinstalling everything, when I would go turn the motor over manually the motor would bind up. I for sure though I had bent a valve with the BC 272s

After poking around I noticed something strange on my exhaust shim/bucket in cylinder #4

Well I spit a shim! That's what caused the threads to strip and dowel to shear.

After doing some research the cause of me spitting a shim was in fact the antilag. The backfires could backfeed onto the exhaust valves relaxing the tension in the spring. If the timing is right, bye bye shim.

Carnage:

The bucket wouldn't come out so a nut was welded to it onto a slide hammer. Came right out

Cleaned back up:

1zz shimless buckets are in there way now

Discuss