Update, it's a week later, drove 35km to work and 35 km back Diff casing temp was 152 F. , and some short distances on the next day 5km to 15km .

The noise has gone down in some conditions and went up in some.

The whine/groan at 59kmh onwards is still there, but the high level of groan goes down at 70kmh, previously it was still noisy at 77kmh.

Starting at 70kmh, the noise is noticably down, and gets lower at 80kmh, i can still hear the gears grinding at 80kmh but its very faint.

I have no idea why it makes so much noise between 59kmh to 69kmh.

Next at coast it used to be almost quiet after letting off throttle at 65 kmh, now there is a bit more noise (still not as loud as drive side)when letting off the gas at 65kmh, and the noise goes down gradually.

At very low coast speeds of 20kmh and under, can still hear the gears grinding faintly, but I think its not really coasting at that speed, I believe the drive side of the R & P is engaging.

I plan to drive the car on some short trips not exceeding 50km at one go in the coming week for several more days, from wednesday to sunday. I think I can total up 500km. So far I only made 140km.

It seems next week, I need to drive to a sounthern state that is 350km away 1 way, So i plan to swap out the diff oil on Sunday. I bet there will be a lot of metal gunk in there. On the long drive I plan to not exceed 100kmh, so far i have not exceed 80kmh.

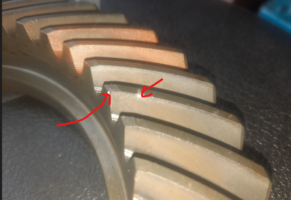

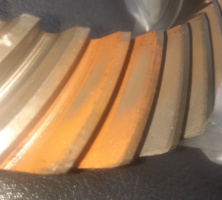

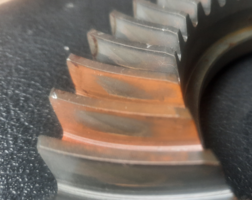

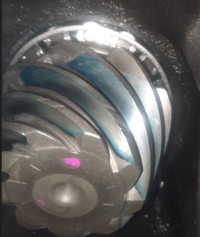

Edit 22 June 2023. I have been driving roughly accumulated distance of 350km thus far. Today is a particularly hot afternoon, and while I was closing in to my workplace, at low speed coasting I could hear the gears grinding. It wasn't this loud when the oil was cold. I have a baaad feeling this break in will not quiet down the gears. Gonna go up to at least 1000km before I make decision, but If I had to change a new ring and pinion, I would sent the carrier out to a machine shop to skim the mounting surface to get back a runout of 0mm vs the 0.07mm. I need to make a quick decision because my workplace will be shifting somewhere else by end of the year. Once that happens no more self rebuilds.

This whole fiasco is delaying my plan to change new JDM wheels and tyres, of which I will not do until this problem is settled along with the 70mph vibration.