Diff rebuild by "pro" not going well

- Thread starter alcyon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ok update. I pmed Piratetip yesterday that that knock is back on reverse, but its very faint. So this morning I finally tested the car. I am glad to report that the diff is as close to perfect as possible, its like 97% there. Hardly any whine in accel and decel, and very faint "knock" at very very low speed decel. I think no one else will notice. I can finally listen to music while driving. I drove all the way to my office gently accelerating and decelerating and it was all smooth.

I am just so glad to wrap this up finally, what more , I would be flying to Italy in a few hours. Special thanks to PirateTip and the guys in Gear Technical Install group on facebook.

I am just so glad to wrap this up finally, what more , I would be flying to Italy in a few hours. Special thanks to PirateTip and the guys in Gear Technical Install group on facebook.

Very interesting thread! Thank you for updating!

Do you happen to have any video or sound recordings of the noises?

Do you happen to have any video or sound recordings of the noises?

Here is a video showing the sound of the diff with the china made ring and pinion.Very interesting thread! Thank you for updating!

Do you happen to have any video or sound recordings of the noises?

Sounds like you got it working.

Has it quiet down any more now with more miles on it?

Glad you persevered and figured it out.

Still strange the ring had damage new out of the box, i have never encountered that before.

You managed to work through a lot of problems, nice job

Has it quiet down any more now with more miles on it?

Glad you persevered and figured it out.

Still strange the ring had damage new out of the box, i have never encountered that before.

You managed to work through a lot of problems, nice job

I havent got the chance to put more miles on it, so far I have only gone about 80km on that Sunday itself. I am still in Italy and will only be back on the 25th. I plan to fill up a tank full and drive till i finish that tank before swapping out to AMSOIL synthetic fluid.Sounds like you got it working.

Has it quiet down any more now with more miles on it?

Glad you persevered and figured it out.

Still strange the ring had damage new out of the box, i have never encountered that before.

You managed to work through a lot of problems, nice job

Ok I am back and drove the car for roughly 2 days for some short trips. Noticed a few things. Overall everything is stiil good. Noise isnt getting worse. I do notice some hum on slow decel (30kmh and less), and some hum on hard accel. Since I am still in the break in period and only put about 280km on the diff, I still got about 400 to 450km to go before I end break in and change diff oil. Have not really got the chance to hammer on the diff, I did accelerate a bit hard off turbo boost and it seems silent enough, however on some load going uphill I do hear some light hum, but then again nothing alarming like before.Any updates?

Have not went beyond 90kmh yet.

More Updates

There is a hum from 80 to 90kmh, but goes away over that speed, I went to 105kmh for a few seconds and its very quiet at that speed.

For the most part, coasting decel is also quiet. There is some whine-hum when throttle is transitioning between accel and decel, when the ring and pinion "floats", but since this condition happens for a short period of time, I feel its nothing to worry about.

There is a hum from 80 to 90kmh, but goes away over that speed, I went to 105kmh for a few seconds and its very quiet at that speed.

For the most part, coasting decel is also quiet. There is some whine-hum when throttle is transitioning between accel and decel, when the ring and pinion "floats", but since this condition happens for a short period of time, I feel its nothing to worry about.

Ok an update. I think everyone know about my propeller shaft rebuild. I just removed it and in the process I rechecked my pinion preload.

It seems to still have preload but I also noticed that it has lost a little preload.

There is a very slight hum especially when the diff "floats", meaning when the gears are not under load, like when I am coasting downhill but I still give it very light throttle, its like the ring and pinion is under minimum load if you get what I mean. When I let go of the throttle and just let it coast there is hardly any sound. On hard acceleration, also hardly any sound. So I was wondering, should I replace this nut and just crank down on a new nut (I have a spare nut) just to get the preload tight again. I shouldn't have to worry about overtightening as there is no crush sleeve in here.

Its just difficult to tighten this nut under the car, even with my companion flange tool. I plan to rest the tool rod on the floor and tighten the center nut, but I have a feeling I would be lifting the whole chassis up a little as I crank hard on the nut.

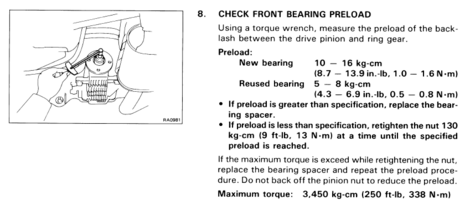

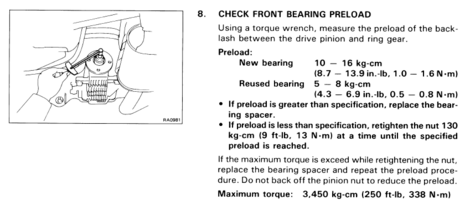

Also I have another question. I re read the TSRM, and according to the wording

"Using a torque wrench measure the preload of the backlash between the drive pinion and ring gear"

Doesn't this mean the break away torque ?

If that is the case then I probably have the pinion preload a bit too high ?

Also notice the illustration shows him checking the torque under the car, meaning it cannot be a constant turning torque.

Another post by turbostreetcar:

It seems to still have preload but I also noticed that it has lost a little preload.

There is a very slight hum especially when the diff "floats", meaning when the gears are not under load, like when I am coasting downhill but I still give it very light throttle, its like the ring and pinion is under minimum load if you get what I mean. When I let go of the throttle and just let it coast there is hardly any sound. On hard acceleration, also hardly any sound. So I was wondering, should I replace this nut and just crank down on a new nut (I have a spare nut) just to get the preload tight again. I shouldn't have to worry about overtightening as there is no crush sleeve in here.

Its just difficult to tighten this nut under the car, even with my companion flange tool. I plan to rest the tool rod on the floor and tighten the center nut, but I have a feeling I would be lifting the whole chassis up a little as I crank hard on the nut.

Also I have another question. I re read the TSRM, and according to the wording

"Using a torque wrench measure the preload of the backlash between the drive pinion and ring gear"

Doesn't this mean the break away torque ?

If that is the case then I probably have the pinion preload a bit too high ?

Also notice the illustration shows him checking the torque under the car, meaning it cannot be a constant turning torque.

Another post by turbostreetcar:

Last edited:

It is the actual torque starting from nothing. It should be a very smooth transition from not rotating to slowly rotating. So, not by measuring higher and then when rotating it lowers. The bearings will fail prematurely this way.

Edit, i have to add this way of measuring is the according the two steps in the manual. So initial preload on the pinion, and later the carrier preload (= total preload-pinion preload). Anyway, it still needs to feel smooth as butter.

But without crush sleeve this is all worthless, the set up of the pinion shaft without the crush sleeve will never be stable. There is a reason why there is a pre-tension close to 300-340Nm.

Edit, i have to add this way of measuring is the according the two steps in the manual. So initial preload on the pinion, and later the carrier preload (= total preload-pinion preload). Anyway, it still needs to feel smooth as butter.

But without crush sleeve this is all worthless, the set up of the pinion shaft without the crush sleeve will never be stable. There is a reason why there is a pre-tension close to 300-340Nm.

Last edited:

I guess I am going to leave it for now, and not go tighter, the irony is the diff was rather quiet with toyota 85W-90 oil, I recently switched to amsoil 75W-110 and there is more noise. I am going to switch back to toyota 85W-90.It is the actual torque starting from nothing. It should be a very smooth transition from not rotating to slowly rotating. So, not by measuring higher and then when rotating it lowers. The bearings will fail prematurely this way.

Edit, i have to add this way of measuring is the according the two steps in the manual. So initial preload on the pinion, and later the carrier preload (= total preload-pinion preload). Anyway, it still needs to feel smooth as butter.

But without crush sleeve this is all worthless, the set up of the pinion shaft without the crush sleeve will never be stable. There is a reason why there is a pre-tension close to 300-340Nm.

In theory, it should be possible to get a proper preload with a hard spacer, I just need to select the correct shim that gives me a breakway torque that isnt so high.

Btw, what are the symptoms of a pinion bearing preload that is too high ?

After swapping the oil I am just gonna drive it for some time and observe if the sound gets worse.

This is to be expected, the oil film is thicker. The mean operating temperature of the diff will normally be around 90C of 194f. You will need to compare the viscosity vs temperature of the different oils. But the base oil for the 85W is already higher in viscosity.I guess I am going to leave it for now, and not go tighter, the irony is the diff was rather quiet with toyota 85W-90 oil, I recently switched to amsoil 75W-110 and there is more noise. I am going to switch back to toyota 85W-90.

I have used a solid spacer in the past, and found it is very cumbersome to get the correct preload using the shims. There is really nothing wrong with a crush sleeve, it take a significant amount of load to actually 'crush' the sleeve and set the bearing preload. I would not bother with a solid spacer again. (perhaps a solid spacer is required for 800Nm + applications)In theory, it should be possible to get a proper preload with a hard spacer, I just need to select the correct shim that gives me a breakway torque that isnt so high.

The slick slip action during measuring the preload for one. Creating more heat in the diff. Can be, or become noisy. But will always drastically shorten bearing life. You could also experience drive line shock or jerks during low speeds and/or disengaging the clutch.Btw, what are the symptoms of a pinion bearing preload that is too high ?

I would suggest to remove the pinion and see how both pinion bearings look. So look for wear signs and feel with your fingernails if you feel anything other than nothing when you go over a single roller. If you feel any roughness, the bearing is already on its way out. I would also suggest to install a crush sleeve and set the bearing preload with the flange holding tool (you will need it)After swapping the oil I am just gonna drive it for some time and observe if the sound gets worse.

Well, after the noise starting to increase in my diff again, I finally decided to take it apart again. After what Dave1jz said and from Zuk's website, I have a feeling my pinion preload was set too high.

On my previous rebuild (new bearings), I was getting over 40inlb breakaway torque, and 14 in lb rolling.

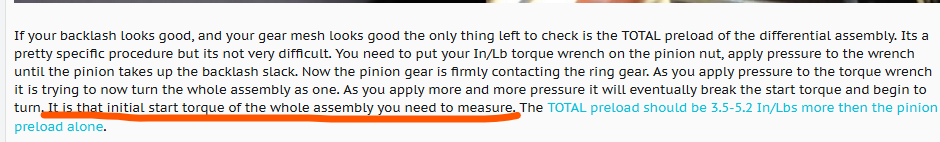

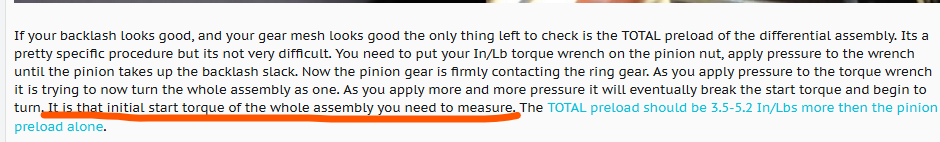

Below, is Zuk's total starting torque :

Since I plan to re-shim the side gears(spider) which have some slop, and the whining noise present when the oil is hot, I am tearing down the diff to inspect the pinion bearings. I strongly suspect the pinion bearings are experiencing premature wear.

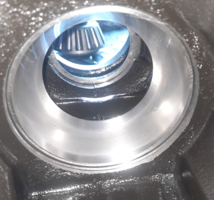

Yesterday I took apart the side gear flanges and diff cover, and did a preload check.

The breawakay torque total is 1.5Nm or 13inlb, and rolling torque is 0.5Nm or 4.5in lb.

That is a massive reduction of preload.

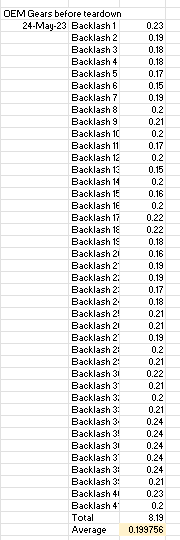

I will be checking backlash and pattern before removing the carrier. These OEM gears have about 1000 miles on them with a 4 time oil change.

I will update my findings here.

Note : my propeller shaft has an imbalance, both the original 2 piece and the new one piece, this also could have contirbuted to the pinion bearing wear. I managed to sourced an untouched used one and will swap that in while installing this rebuilt diff.

On my previous rebuild (new bearings), I was getting over 40inlb breakaway torque, and 14 in lb rolling.

Below, is Zuk's total starting torque :

Since I plan to re-shim the side gears(spider) which have some slop, and the whining noise present when the oil is hot, I am tearing down the diff to inspect the pinion bearings. I strongly suspect the pinion bearings are experiencing premature wear.

Yesterday I took apart the side gear flanges and diff cover, and did a preload check.

The breawakay torque total is 1.5Nm or 13inlb, and rolling torque is 0.5Nm or 4.5in lb.

That is a massive reduction of preload.

I will be checking backlash and pattern before removing the carrier. These OEM gears have about 1000 miles on them with a 4 time oil change.

I will update my findings here.

Note : my propeller shaft has an imbalance, both the original 2 piece and the new one piece, this also could have contirbuted to the pinion bearing wear. I managed to sourced an untouched used one and will swap that in while installing this rebuilt diff.

Last edited:

If the backlash opened up there was probably not enough preload on the carrier bearings.

Why did you set the pinion preload so high?

I thought previously you had preload spot on? ~12-15in/lbs starting torque on new bearings.

40in/lbs is way too high for starting torque.

Why did you set the pinion preload so high?

I thought previously you had preload spot on? ~12-15in/lbs starting torque on new bearings.

40in/lbs is way too high for starting torque.

Hi Piratetip, i probably will increase carrier shim thickness by an additional 0.03mm just to tight up more. I find the work much easier to do once i removed the side seals. About the pinion preload, i concentrated on the rolling torque not breakaway, thats what everyone said, the rolling torque was fine. It seems my pinion bearings are on its way out. They have some light pitting. Will be taking pics and posting in a few days time.If the backlash opened up there was probably not enough preload on the carrier bearings.

Why did you set the pinion preload so high?

I thought previously you had preload spot on? ~12-15in/lbs starting torque on new bearings.

40in/lbs is way too high for starting torque.

I have a theory about the backlash opening up, I was thinking of setting up the backlash with the "old" carrier bearings, that way I would know what will be the backlash once the bearings break in. Then swap over the new bearings (old bearing has false brinelling marks on side opposite ring gear) with same side shims, the backlash will be intially tighter by 0.002"

Here are some pics of two sets of depth, 0.073" and 0.067"

Next I went shallow at 0.067", look how far off the coast has become.

Next : 0.0083"(2.1mm) and 0.0076"(1.94mm Original shim). I also plan to make a 0.0075" (1.90mm).

I suspect my final setup will be anywhere from 0.0073" to 0.0076".

Last edited: