Diff rebuild by "pro" not going well

- Thread starter alcyon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

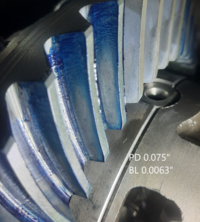

Ok I got all 5 data points compiled

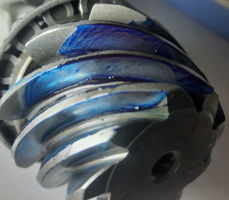

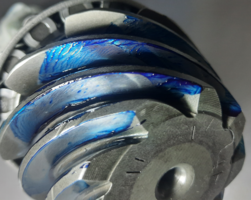

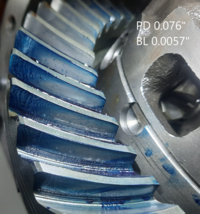

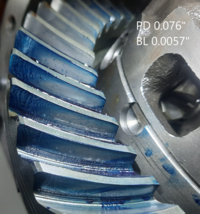

1st, lets go Ultra shallow, Drive Side heel bias, half rugby ball shape

Coast off the face and over the toe

Next Ultra Deep, Coast slight heel bias

Drive slight toe bias

Next ideal 1

Coast seems ok but running off the toe

Drive , seems ideal pattern with full rugby ball shape

Cont next post

1st, lets go Ultra shallow, Drive Side heel bias, half rugby ball shape

Coast off the face and over the toe

Next Ultra Deep, Coast slight heel bias

Drive slight toe bias

Next ideal 1

Coast seems ok but running off the toe

Drive , seems ideal pattern with full rugby ball shape

Cont next post

Attachments

Last edited:

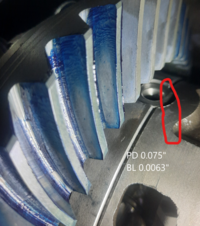

Next , little more shim, Coast looks nice and not running off the toe with wide contact patch

View attachment 81391

Drive, partial rugby ball shape above but straight bottom, bigger contact patch than 0.073", still within toe edge

View attachment 81393

View attachment 81394

Last shim, stock shim

Not ideal shape, but coast has large contact patch and still within toe

Drive, not ideal shape, but long and wide contact patch

So please help me decide. is the rugby ball shape or wide long patch better ?

View attachment 81391

Drive, partial rugby ball shape above but straight bottom, bigger contact patch than 0.073", still within toe edge

View attachment 81393

View attachment 81394

Last shim, stock shim

Not ideal shape, but coast has large contact patch and still within toe

Drive, not ideal shape, but long and wide contact patch

So please help me decide. is the rugby ball shape or wide long patch better ?

Piratetip, i have not checked breakaway torque for pinion or carrier as I have not changed any of the bearings yet. My logic since the bearings only have 1000 miles on them their wear is minimal and I can avoid risk of damaging the new bearings by pressing off the pinion bearings so many times and inserting the carrier 5 to 7 times. I will be changing the pinion bearings today and shooting for breakaway torque of no more than 16 in lb..076" is perfect.

Run it.

Also the backlash is quite good.

I shoot for .0055", maybe a hair higher depending on what I am setting it up for usage wise.

What is the breakaway torque on the carrier bearings only?

Changing carrier bearings would be tomorrow.

My target for carrier bearings is 3 to 5 in-lb

so the total should not exceed 20 in-lb.

Also could you illustrate on one of my pinion photos what would constitute a good pattern ?

I am in agreement on your preload targets.

I would shoot for 13in/lbs on pinion breakaway, with pinion nut somewhere around 160ft/lbs.

Carrier bearings at 5in/lbs is a good target.

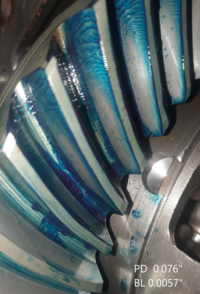

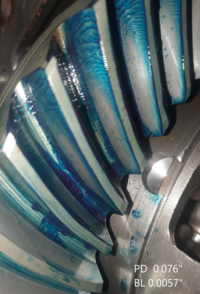

The pinion shows good pattern because it's a hair shallow and the "comet tail" is pulling only a bit to the center.

Indicates the pinion is slightly deep which you want to shoot for.

Reason for this is gear deflection under load, they separate slightly and the pattern shifts up the tooth during operation.

Turns your slightly deep pattern into a perfectly centered pattern.

This is important to keep the pattern low on the Ring gear tooth as it's the weak point in the system.

Pinion survives nearly anything with hardly any damage vs. ring.

I have some failed gear sets that show clear evidence of this due, to the position broken off the Ring gear tooth and other strange high wear patterns that develop.

This is typically on high power builds 600hp+.

I would shoot for 13in/lbs on pinion breakaway, with pinion nut somewhere around 160ft/lbs.

Carrier bearings at 5in/lbs is a good target.

The pinion shows good pattern because it's a hair shallow and the "comet tail" is pulling only a bit to the center.

Indicates the pinion is slightly deep which you want to shoot for.

Reason for this is gear deflection under load, they separate slightly and the pattern shifts up the tooth during operation.

Turns your slightly deep pattern into a perfectly centered pattern.

This is important to keep the pattern low on the Ring gear tooth as it's the weak point in the system.

Pinion survives nearly anything with hardly any damage vs. ring.

I have some failed gear sets that show clear evidence of this due, to the position broken off the Ring gear tooth and other strange high wear patterns that develop.

This is typically on high power builds 600hp+.

Oh dear, i was instaliling the bearing races, and once i was done with the front race, i had a look and noticed a smudge on the inner race. I should have checked earlier. My repeated attempts to spray with brake clean and wipe has not removed it. I ran my fingers and finger nail over the area and feel nothing, its smooth. Now should I change this or go ahead and use it ?

5th June

Pinion preload without seal

Breakaway - 13inlb

Rolling 7 in lb

Total carrier shim 2.94+2.88 = 5.82mm

Breakaway 19inlb , rolling 11inlb

With Carrier shim 2.91+2.94 = 5.85

Breakaway 22inlb

So I went with 19inlb shim set.

Next will be checking backlash, final gear pattern, and listen for noise.

If it's ok, Install all seals, clean up all prussian blue without removing carrier, change circlips, button it up. My guess it should be done on the 8th of June.

Pinion preload without seal

Breakaway - 13inlb

Rolling 7 in lb

Total carrier shim 2.94+2.88 = 5.82mm

Breakaway 19inlb , rolling 11inlb

With Carrier shim 2.91+2.94 = 5.85

Breakaway 22inlb

So I went with 19inlb shim set.

Next will be checking backlash, final gear pattern, and listen for noise.

If it's ok, Install all seals, clean up all prussian blue without removing carrier, change circlips, button it up. My guess it should be done on the 8th of June.

Last edited:

Those numbers look very good.

Interested to see your pattern and backlash

Interested to see your pattern and backlash

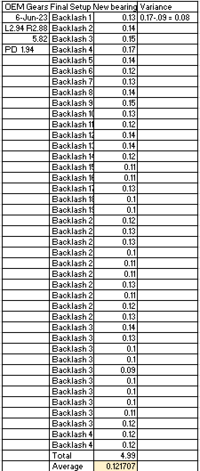

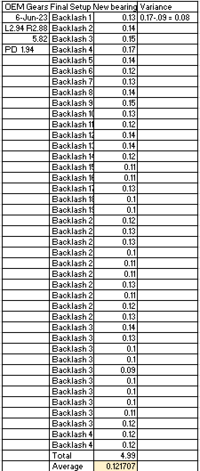

Final Backlash averages (out of all 41 tooth) out at 0.0048" (0.12mm), just a tiny bit under 0.005". Currently has 2.94mm on L, 2.88mm on R. I need 2.91mm shims on both sides to get the backlash to be at 0.0055" but I only have one 2.91mm shim. I think its ok as the rotation test is not noisy, and I think backlash will probably open up a little later on. Besides I think with this backlash maybe I could eliminate my clunking in shifting to D and R

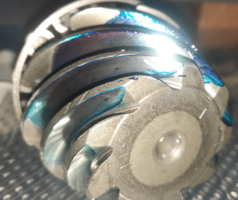

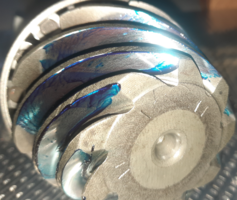

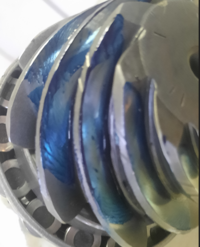

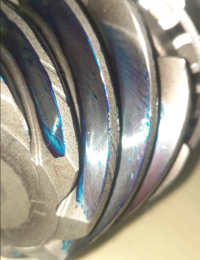

gear Pattern :

Is it ok to send it with this backlash ? If not then I must get one 3.15mm shim cut down to 2.91mm, so i will have same preload as now , but have a backlash of 0.14mm (0.0055"). However, If i were to follow the TSRM telling me to check in 4 to 6 different places on the ring gear I could definitely get values within the range 0.13 to 0.17

gear Pattern :

Is it ok to send it with this backlash ? If not then I must get one 3.15mm shim cut down to 2.91mm, so i will have same preload as now , but have a backlash of 0.14mm (0.0055"). However, If i were to follow the TSRM telling me to check in 4 to 6 different places on the ring gear I could definitely get values within the range 0.13 to 0.17

Last edited:

Pattern is good.

Backlash is a bit tight, but you maybe? Could get away with it.

If it were me I would shift to 0.0055", swap out with the proper side shims.

When the diff components heat up they expand slightly and the backlash decreases.

By how much exactly? Don't know.

This is where having 2x of all available shim sizes comes in handy.

These diffs are hard to setup without the right parts on hand. (As you already know)

Backlash is a bit tight, but you maybe? Could get away with it.

If it were me I would shift to 0.0055", swap out with the proper side shims.

When the diff components heat up they expand slightly and the backlash decreases.

By how much exactly? Don't know.

This is where having 2x of all available shim sizes comes in handy.

These diffs are hard to setup without the right parts on hand. (As you already know)

The reason i think i can get away with it is..

As you can see many individual measurements are over the lowest limit of 0.13, So I dont think the gears will get stuck , and since this carrier preload is the same before, I think the backlash will open up again down the line, by not more than 0.05mm or 0.002". In gear install technical group(Facebook), some people has stated the same thing that they encountered.

Thanks for the shim offer, my machinist could grind a shim down in 1 to 2 days.

I am just worried that the pinion will dig into the flank of the ring gear tooth, but I guess backlash cant do that, as the pinion depth looks ok.

As you can see many individual measurements are over the lowest limit of 0.13, So I dont think the gears will get stuck , and since this carrier preload is the same before, I think the backlash will open up again down the line, by not more than 0.05mm or 0.002". In gear install technical group(Facebook), some people has stated the same thing that they encountered.

Thanks for the shim offer, my machinist could grind a shim down in 1 to 2 days.

I am just worried that the pinion will dig into the flank of the ring gear tooth, but I guess backlash cant do that, as the pinion depth looks ok.

Yeah its right on the edge.

I don't like how many 0.1 measurements were in there though.

Do you have around 0.001" of runout on the ring gear when you spin it in the case?

Might be something to check as well.

I don't like how many 0.1 measurements were in there though.

Do you have around 0.001" of runout on the ring gear when you spin it in the case?

Might be something to check as well.