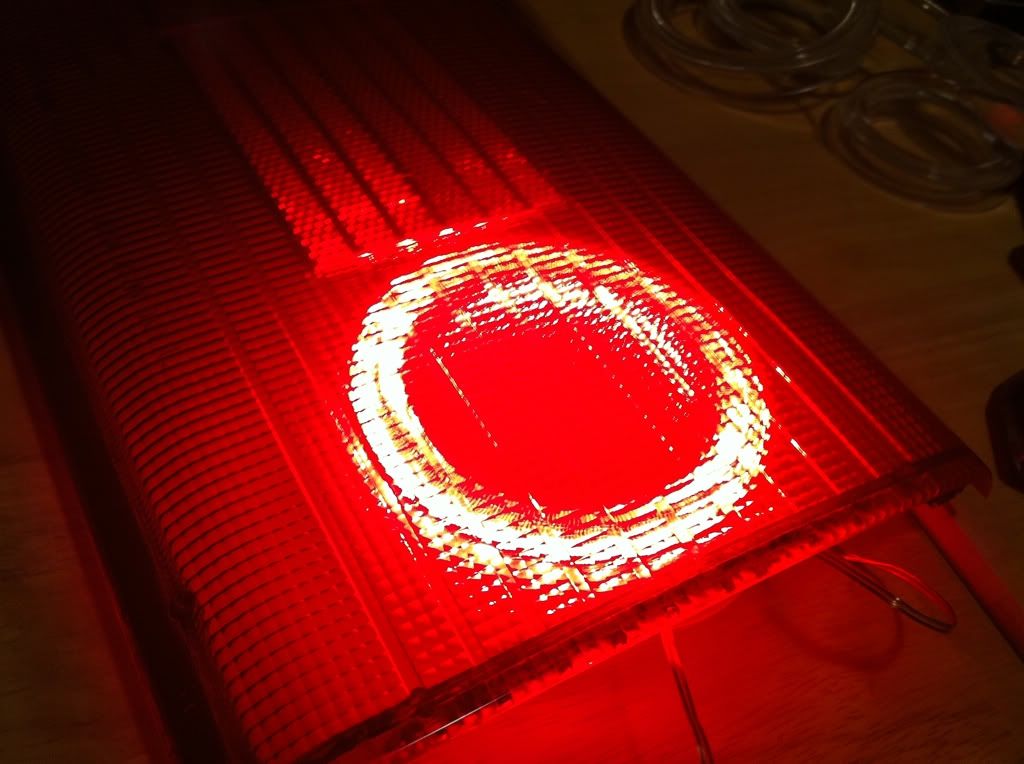

Check it out, quality shave and color change...Body work is finished!

- Thread starter Kalos

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks for the kind words.

I've been trying to decide what material to use as a backer on which to mount my LEDs. I wanted something durable, thin enough to fit inside the "frame" that the lens glues to, and also a material that I can shape to exactly match the curvature of the lens itself. I decided to use the lens as a mold and I tried casting a plastic backer piece....

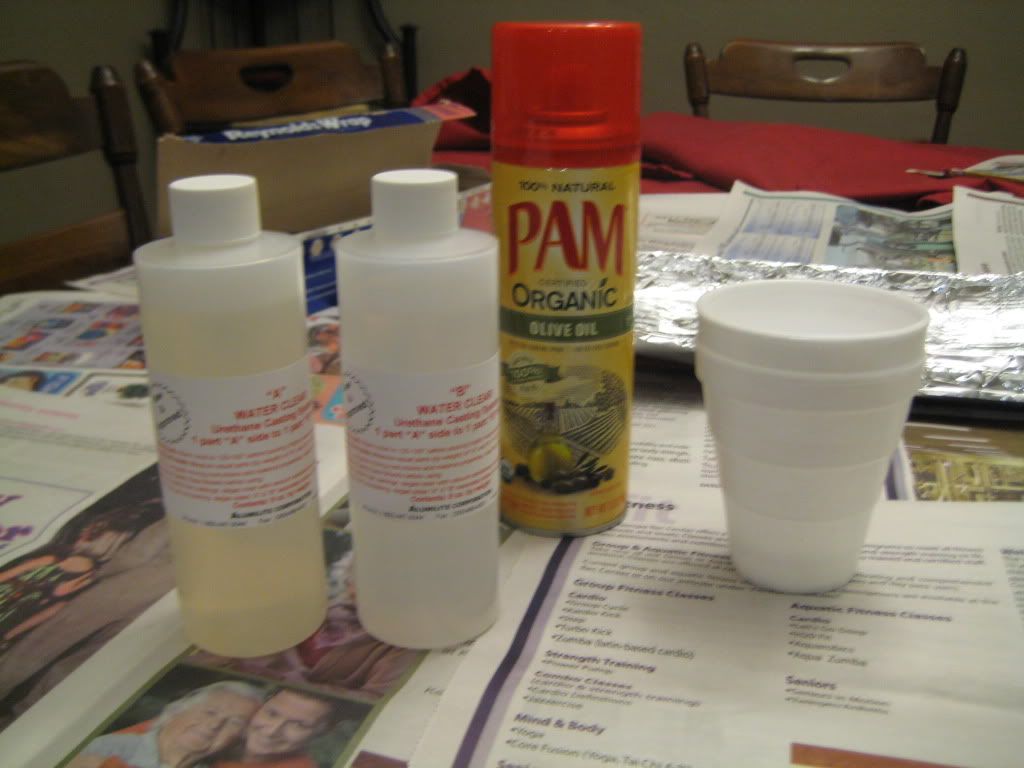

Materials:

MK3 taillight as the mold

Two part liquid plastic

Aluminum foil

Nonstick cooking spray

Wrapped the inside of the taillight in aluminum foil, making extra sure there were no gaps or tears that would leak plastic onto the lens for permanently marred surface...

Pour the two equal amounts of plastic into one container, stir, then pour into the taillight. Depending on the plastic you use, the "pot" time or amount of time you have before hardening can be very different. Gently rotate the lens so as the plastic hardens, the depth stays even. Once it is no longer liquid, leave it in place for it to fully harden (again, time is dependent on the product you use). Don't pull the cast out of the taillights before it has hardened because the shape will sag.

I pulled it out of the lens this morning -- its strong but thin, it has great resistance to shear but not to bending forces. That's okay, because it will be sandwiched between the lens and the black "frame" piece and with that support it will never break. I bought this liquid plastic at a local hobby store and it seems to work just fine, though it has a much longer pot life that I would have liked. I have used Smooth Cast 300 in the past on a different project and I liked it's timing better but I can only find it online and its much more expensive to purchase and ship.

I've been trying to decide what material to use as a backer on which to mount my LEDs. I wanted something durable, thin enough to fit inside the "frame" that the lens glues to, and also a material that I can shape to exactly match the curvature of the lens itself. I decided to use the lens as a mold and I tried casting a plastic backer piece....

Materials:

MK3 taillight as the mold

Two part liquid plastic

Aluminum foil

Nonstick cooking spray

Wrapped the inside of the taillight in aluminum foil, making extra sure there were no gaps or tears that would leak plastic onto the lens for permanently marred surface...

Pour the two equal amounts of plastic into one container, stir, then pour into the taillight. Depending on the plastic you use, the "pot" time or amount of time you have before hardening can be very different. Gently rotate the lens so as the plastic hardens, the depth stays even. Once it is no longer liquid, leave it in place for it to fully harden (again, time is dependent on the product you use). Don't pull the cast out of the taillights before it has hardened because the shape will sag.

I pulled it out of the lens this morning -- its strong but thin, it has great resistance to shear but not to bending forces. That's okay, because it will be sandwiched between the lens and the black "frame" piece and with that support it will never break. I bought this liquid plastic at a local hobby store and it seems to work just fine, though it has a much longer pot life that I would have liked. I have used Smooth Cast 300 in the past on a different project and I liked it's timing better but I can only find it online and its much more expensive to purchase and ship.

Thanks!

So about a year ago I pulled some projector headlight housings from a vehicle at the junkyard for a potential low-rise headlight alteration. Today I was working on the bump stops on my headlights because they close too low in the bumper and I thought I'd see how the projectors look:

Clearly, the frame would need a little trimming to get the lights to fit, but it wouldn't take much. What do you think?

So about a year ago I pulled some projector headlight housings from a vehicle at the junkyard for a potential low-rise headlight alteration. Today I was working on the bump stops on my headlights because they close too low in the bumper and I thought I'd see how the projectors look:

Clearly, the frame would need a little trimming to get the lights to fit, but it wouldn't take much. What do you think?

I'd be up for that

I think I'm gonna start soldering tomorrow actually. I've been agonizing over the design details, worrying that I'll change my mind after it's too late or something. But I've finally got my design (BTW, no circles) and I'm ready to get started!

I think I'm gonna start soldering tomorrow actually. I've been agonizing over the design details, worrying that I'll change my mind after it's too late or something. But I've finally got my design (BTW, no circles) and I'm ready to get started!