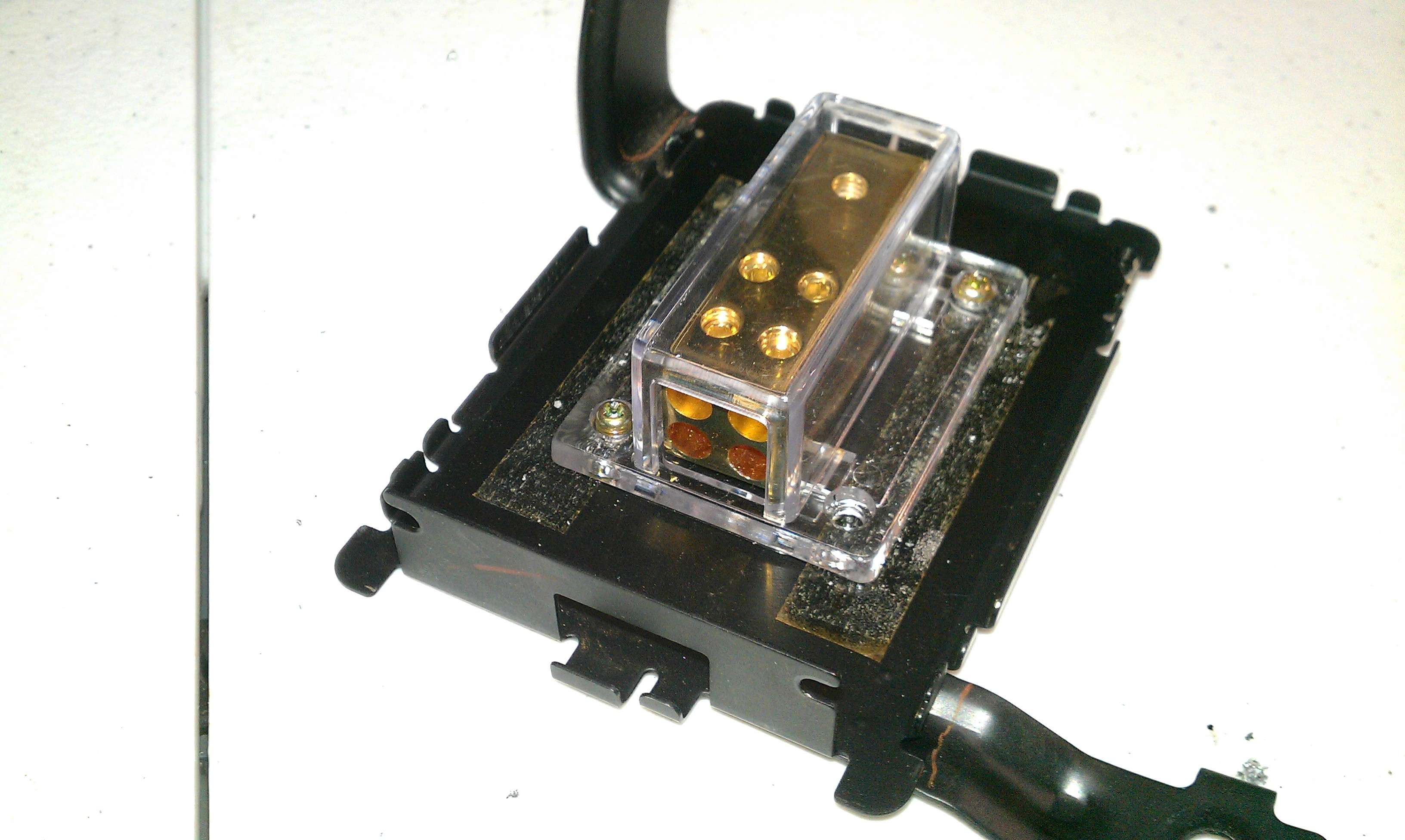

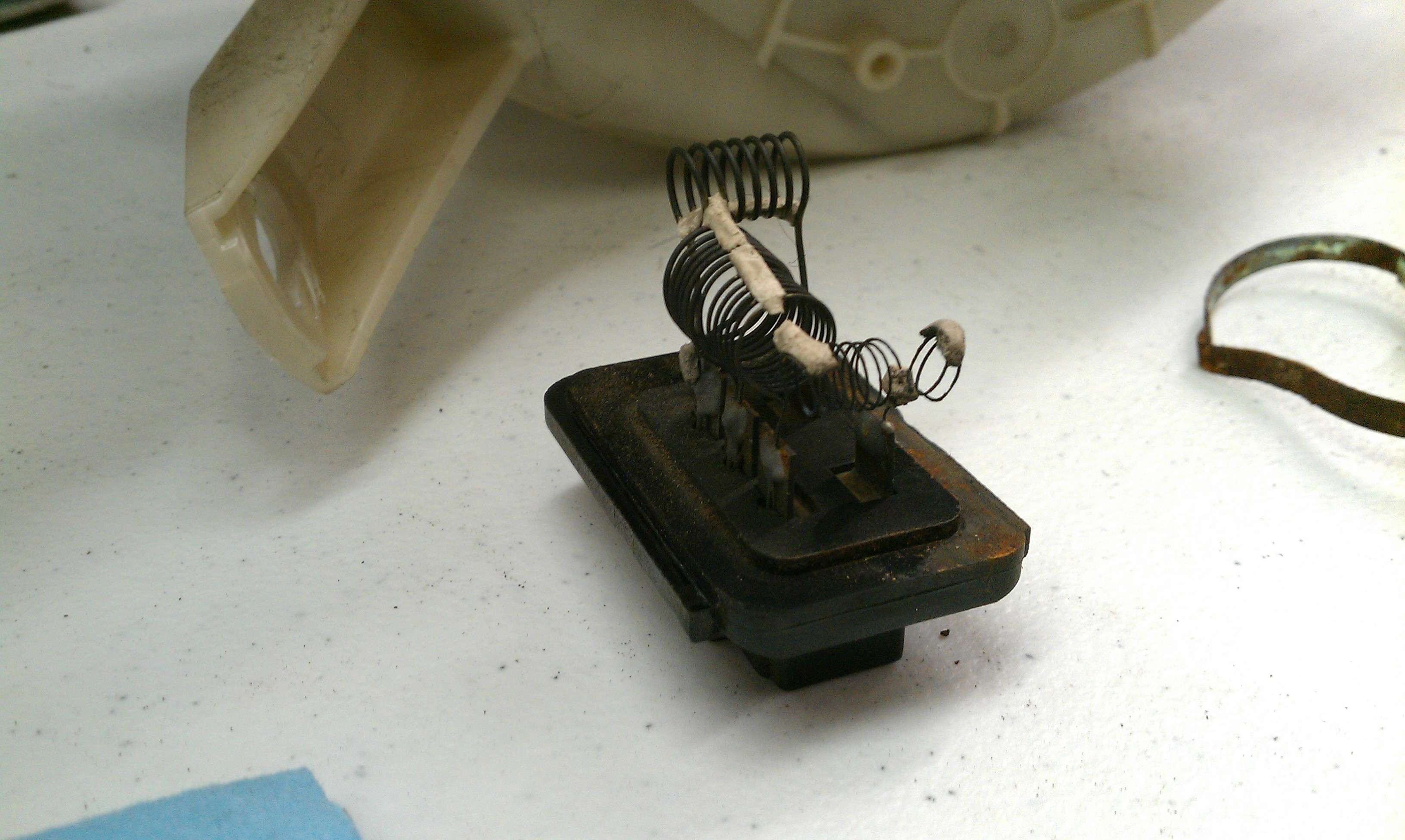

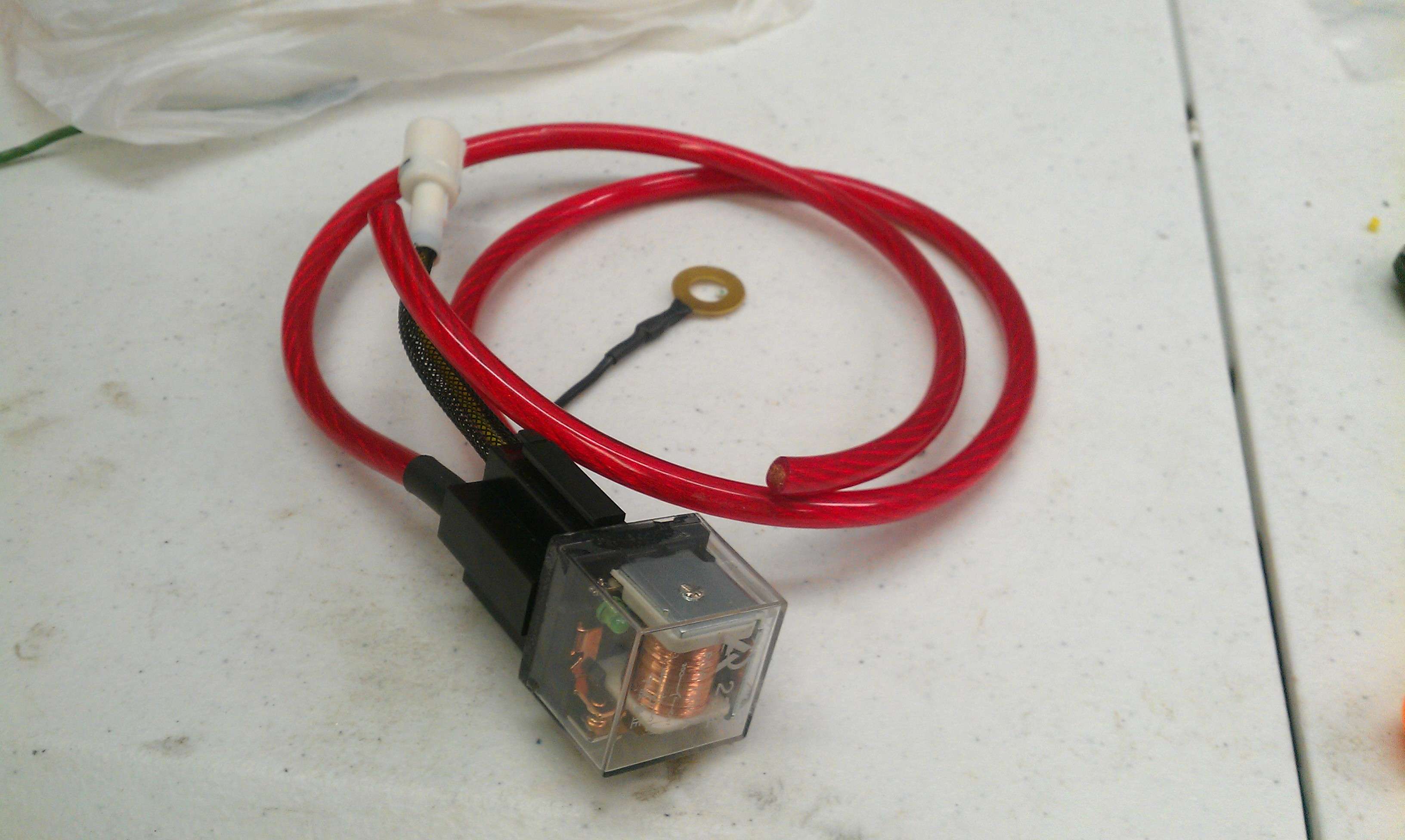

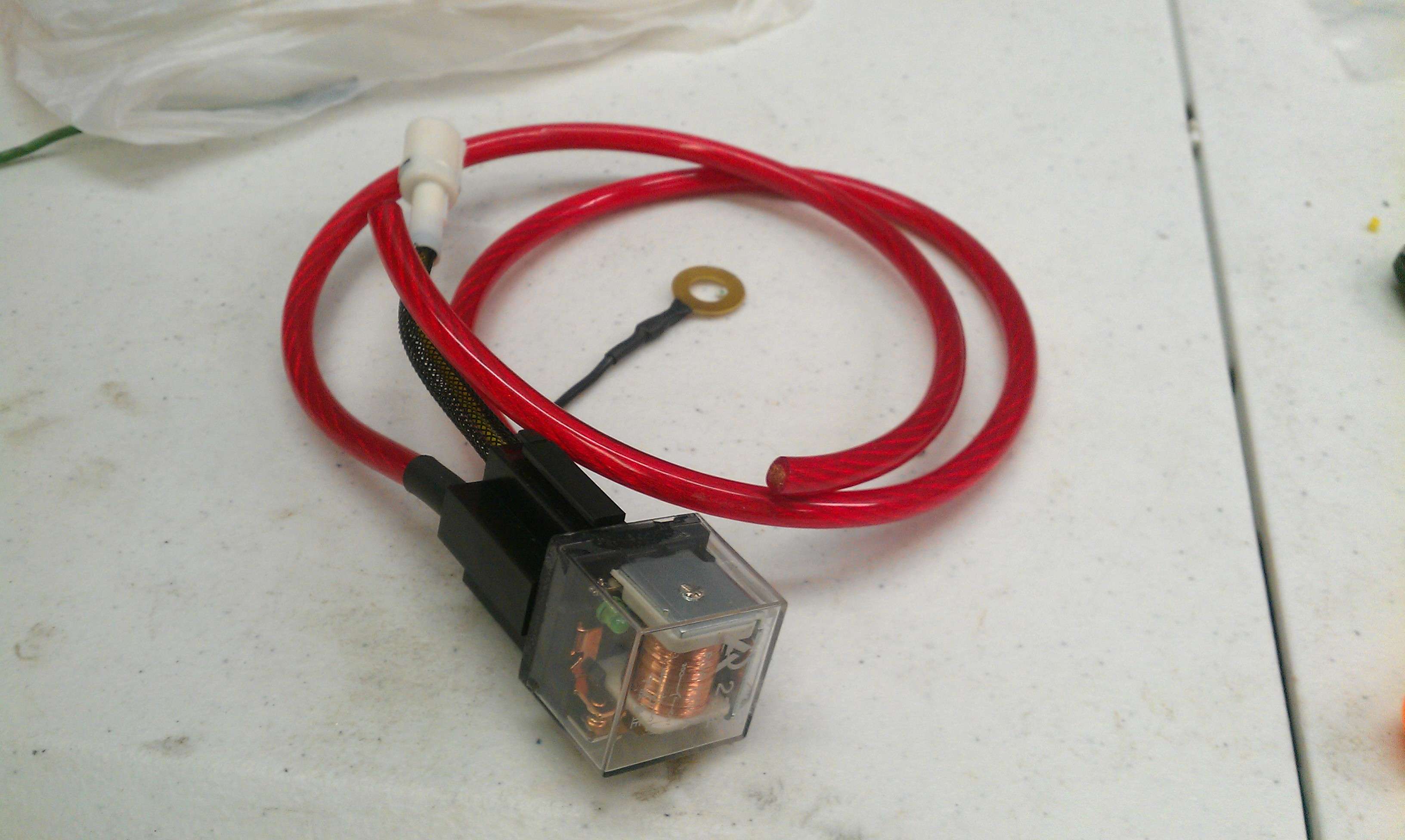

I finished with the heater control valve assembly, I really like how it turned out. Along with the new rehostat I re-installed all the "ductwork" for the HVAC with new foam on all the sealing points. I also finished the power distribution for switched 12v+ in the cabin, I have 8ga wire running from the battery to a relay that will excite when the key is on accsory or on, then the power splits up; one to the AMP for the sub, and one to power any extra stuff I'm running such as gauges and relays. For a while I have had a set of gauges I picked up from another local Supra owner, Daemon ones. They are electronic 60mm ones. I have been fighting with my self trying to pick a spot for them. I fabbed up a fiberglass gauge pod but it was stupid huge and looked bad. I then thought, wait... I have sheet metal, soda cans, and a welder. I can make this out of metal! So I did, I first mocked it up and then built a backing plate. From there I tacked on the plate I bent that the gauge pods mount to. Then I filled in the empty spots with more sheet metal. I'm very happy with the results. I'm not master welder but this turned out nice. I even have a spot to mount a switch for my electric fan relay circuit.

Started off with some layouts, and taking measurements, and moching it all up:

The wiring fits perfectly:

Final: