Chambers Build Thread - "Daily Eighty-Seven"

- Thread starter Chambers

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I also got around to installing my CF spoiler temporarily, it will have to come off to fix the holes from the factory spoiler but I was tired of seeing it sit. But, disaster struck, over the night the clamp on the passenger side fell off and left me with a paint chip to metal and a dent with a nice scratch. I was able to do a basic repair on it but I'm no body guy.

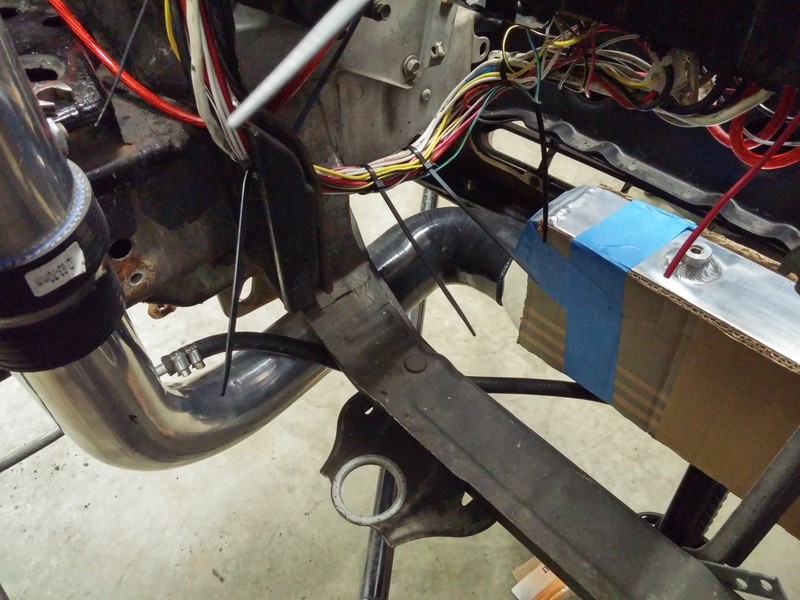

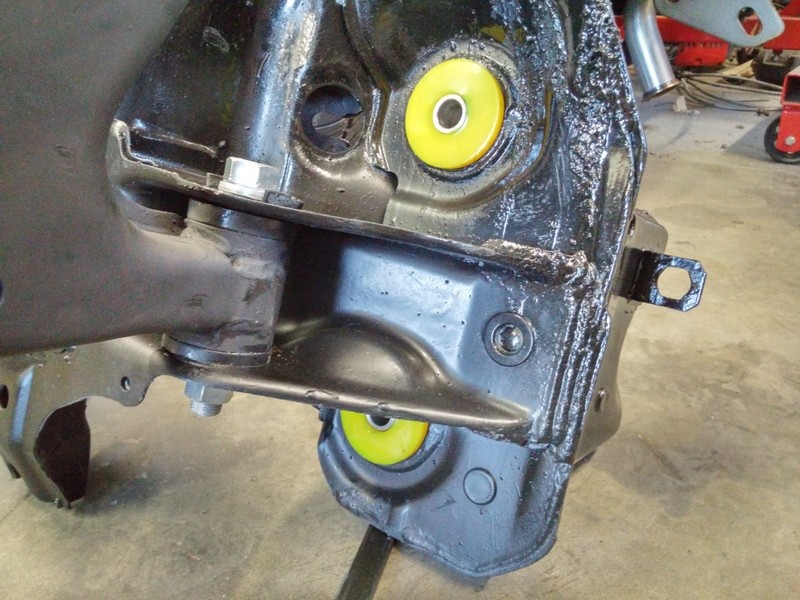

I have also started collecting parts to rebuild the front suspension and sub frame. I need to actually swap sub frames because mine was modded years ago to fit the UZ, after the swap I will be able to use swap brackets. The engine will sit slightly more forward and up from what I have now preventing the steering shaft from rubbing the heat shield during hard acceleration in right turns.

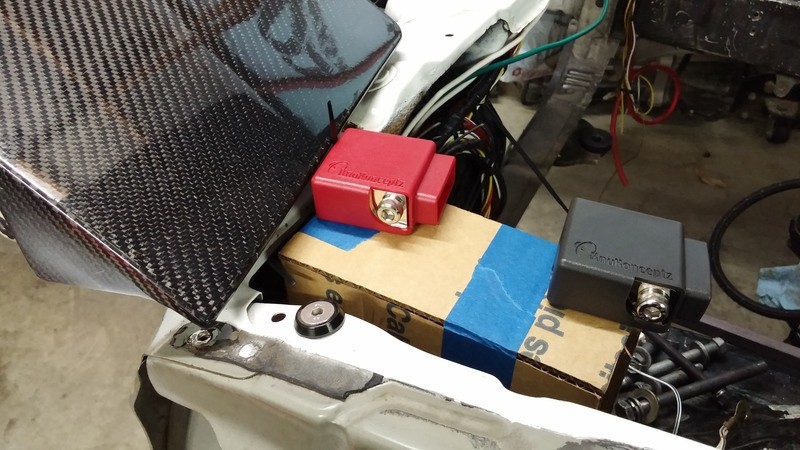

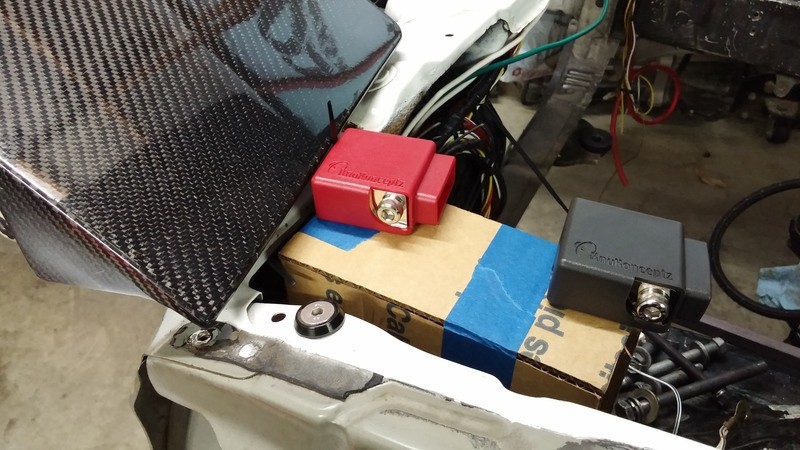

Some other parts came in, I got a AFPR preparing for the SC and a wideband to monitor the engine. I have installed the wideband and it runs PIG rich! The new piping is for my new down pipes (from the soon to be OBX headers).

[video=youtube;TxYjU-n4J20]https://www.youtube.com/watch?v=TxYjU-n4J20&list=UUeYZOKssklnW6F529Y-NDKw[/video]

And finally something small I picked up to bring just the right amount of color into the engine bay:

I have also started collecting parts to rebuild the front suspension and sub frame. I need to actually swap sub frames because mine was modded years ago to fit the UZ, after the swap I will be able to use swap brackets. The engine will sit slightly more forward and up from what I have now preventing the steering shaft from rubbing the heat shield during hard acceleration in right turns.

Some other parts came in, I got a AFPR preparing for the SC and a wideband to monitor the engine. I have installed the wideband and it runs PIG rich! The new piping is for my new down pipes (from the soon to be OBX headers).

[video=youtube;TxYjU-n4J20]https://www.youtube.com/watch?v=TxYjU-n4J20&list=UUeYZOKssklnW6F529Y-NDKw[/video]

And finally something small I picked up to bring just the right amount of color into the engine bay:

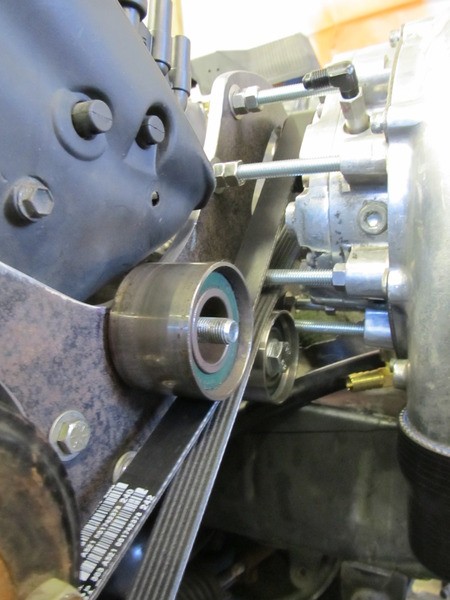

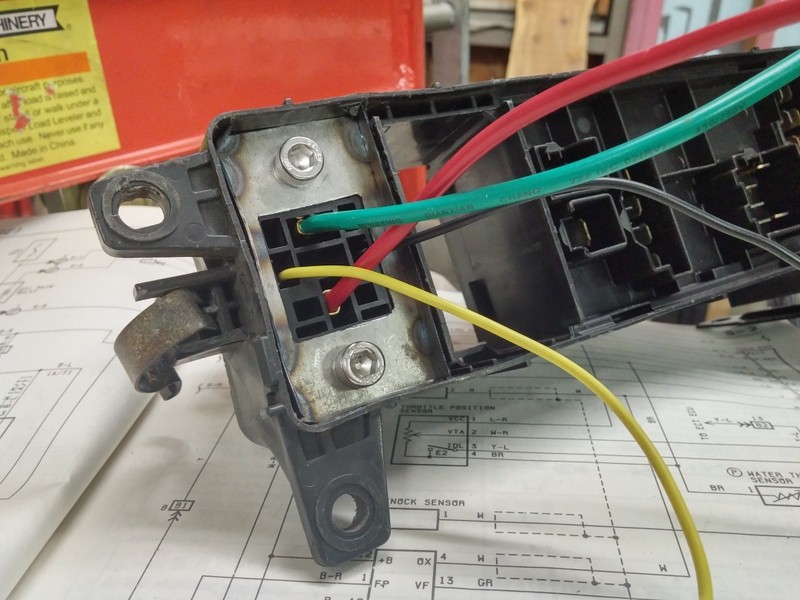

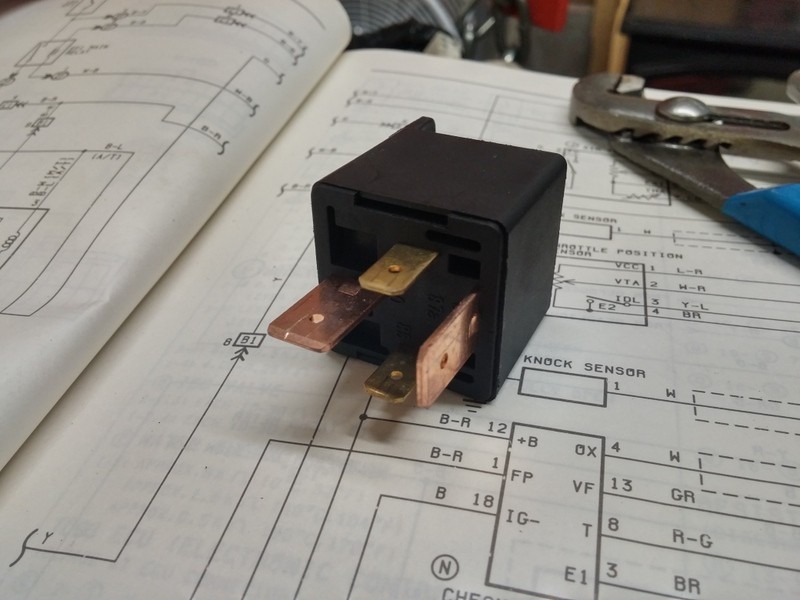

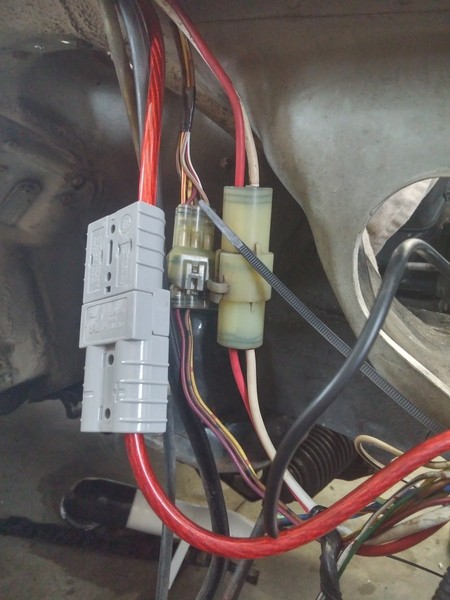

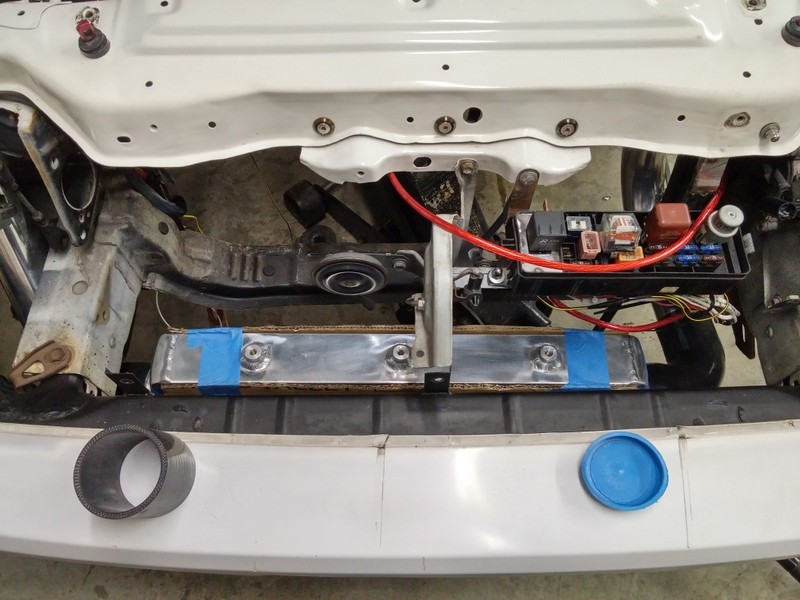

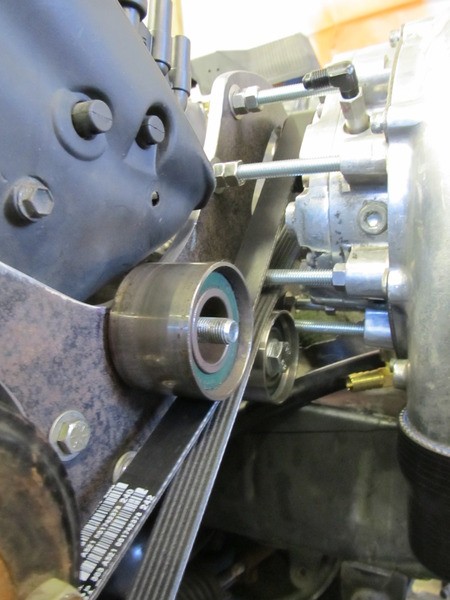

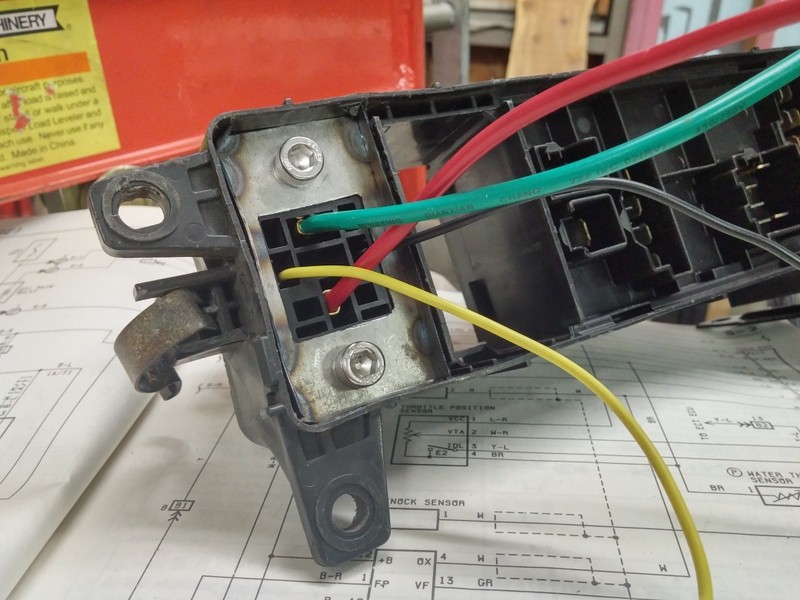

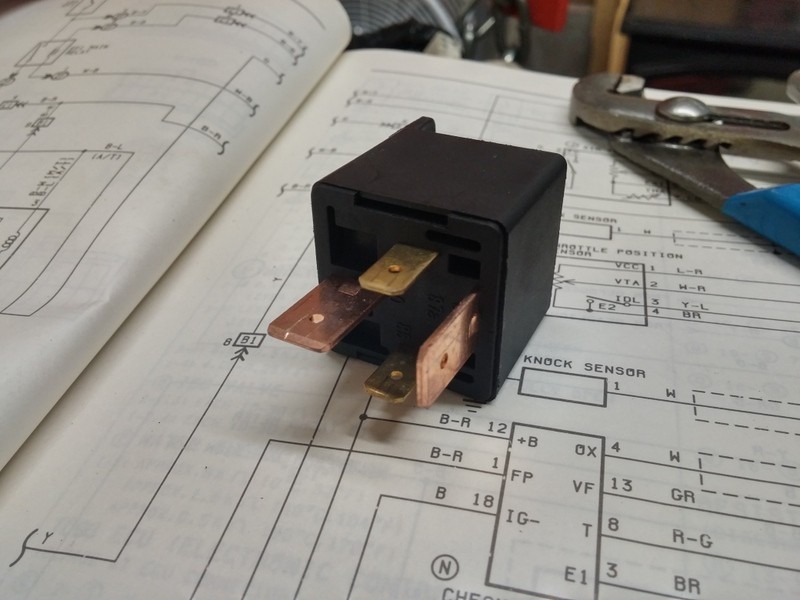

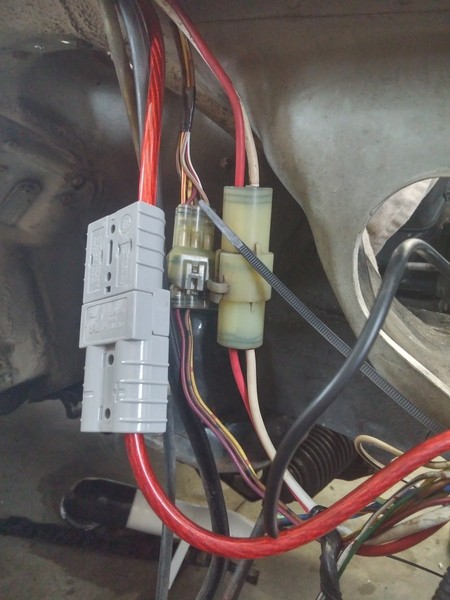

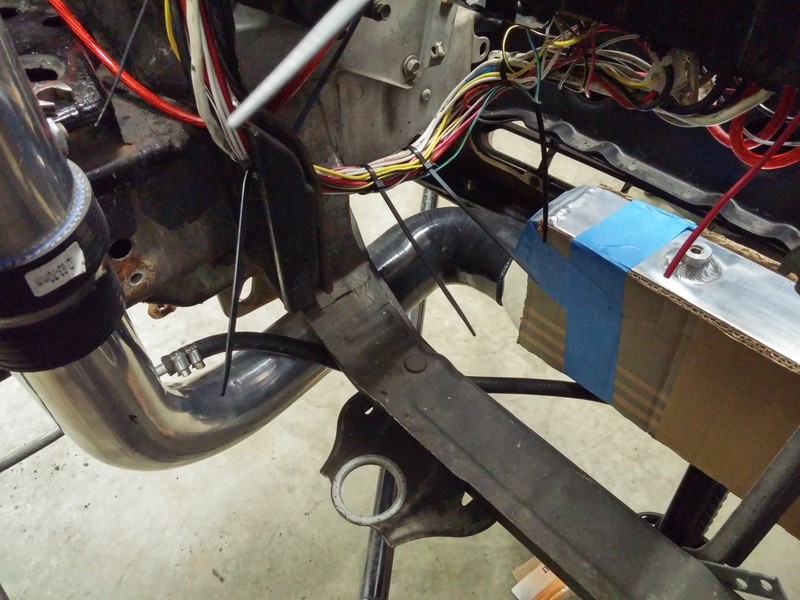

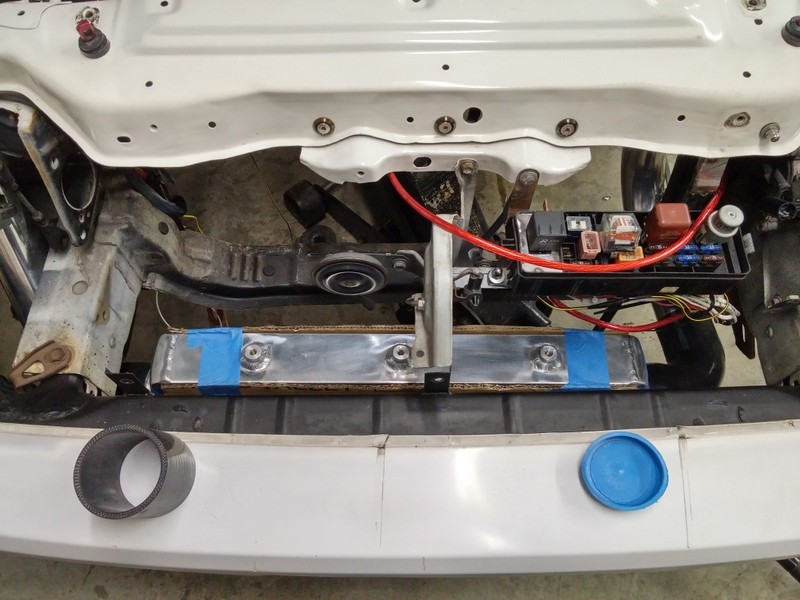

A lot has been happening, got the supercharger mounted, fabbed up some IC pipes. I'm in the process of mounting the IC and fabbing the exhaust now. I also relocated the fuse box in the engine bay and customized my engine harness/ body harness so ALL of the wires go into the cab via the firewall. I have no connections from the engine to the front of the car other than the alternator wires. It really cleans it up!

I will let the pics do most of the talking though, in no particular order:

I will let the pics do most of the talking though, in no particular order:

Very nice work. There's no manual for what you're doing and I know that makes it way more difficult. I hope it pays off and you really enjoy the end product!

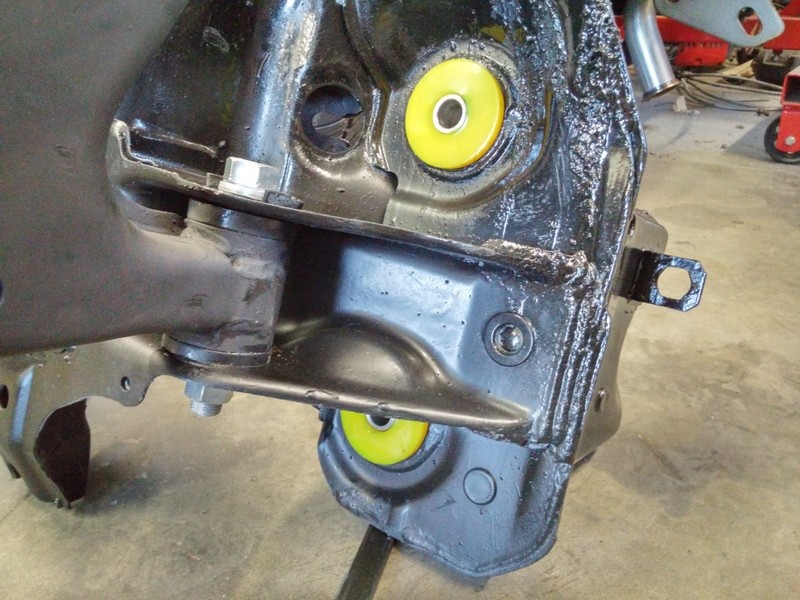

Work continues; When I removed the hood one of the bolts had rusted a bit... the guy who built the hood put nuts in some sort of foam under the CF, so when its a little rusty and you apply torque to remove it the foam breaks down and the nut spins............. Also removed the sub frame bushings, the fronts came out with little effort, but 4 out of 6 on the rear required a lot of work to remove... When the rear was removed I found some rust, and its in a very strange place, its on the frame rail, split in the middle and cracked like a windshield from who knows what. This is going to get repaired and everything will be going back together soon. I used the internal frame coating system from Eastwood, it seems to work very well, good coverage but I think it would take 4 or 5 cans to do the frame rails on the Supra, one can just took care of the front 6 or so feet. I also removed the battery tray, nice and clean! The engine bay body work is the major item being worked on now!

Did you take a dremel to the tray and pry it up one part at a time? Thanks again for the connector pins

Kinda, I used a cordless angle grinder with a cut wheel, corded angle grinder with a grinding wheel, an air angle grinder with a small cut wheel, and another air angle grinder with a sand paper disk attachment! This was the second one I have removed, they put A LOT of spot welds on the thing, I was able to get this one out much quicker than the first.

Your welcome!

Your welcome!

Got some more work done, new bushings in the front upper and lower control arms, new sub frame bushings in both front and rear, started assembling the front sub frame, started re-finishing misc engine bay components, and did a bit of body work where the battery tray used to be. A friend who welds for a living also helped me out by fixing the rust on the rear frame rail. It was a royal PITA! And I still have some other bits of rust to fix back there before the rear sub frame can be put back.

In no particular order:

In no particular order: