well you know me me...

Today was a bushing day and I did it with twist thou because I really hate squeaky polly bushings.

First off I really hate to burn bushings out but I had to burn the left over after using window cutting wire it works well saves time on the uppper bushings.

The lower arms are well easy as **** since ya just made 3 drills and popped out with a pry bar after cutting off the over hang of the stock bushings.

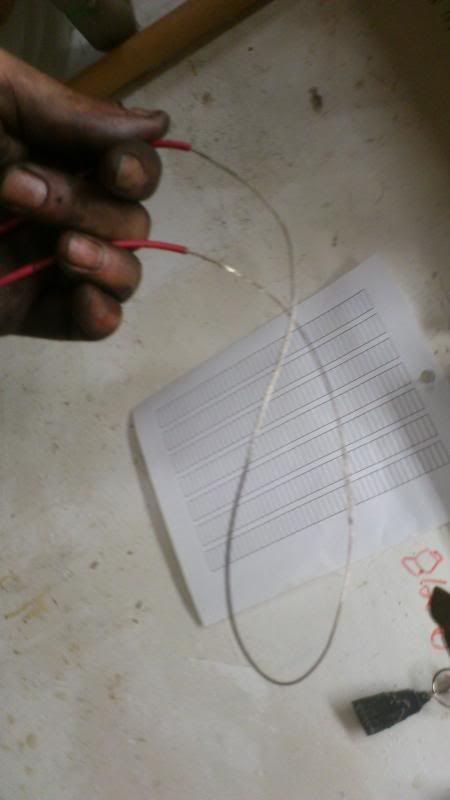

the upper bushing was well crappy since I had break away the eye let race after drilling some holes in the rubber and use a vise to hold it all and then use a braided wire to cut most of the rubber out.

When the rubber was cut I used a torch to burn off the residue

then I installed the greash fittings

ps The bread knife is the best to use to cut rubber even it is dual as **** it well cut like butter

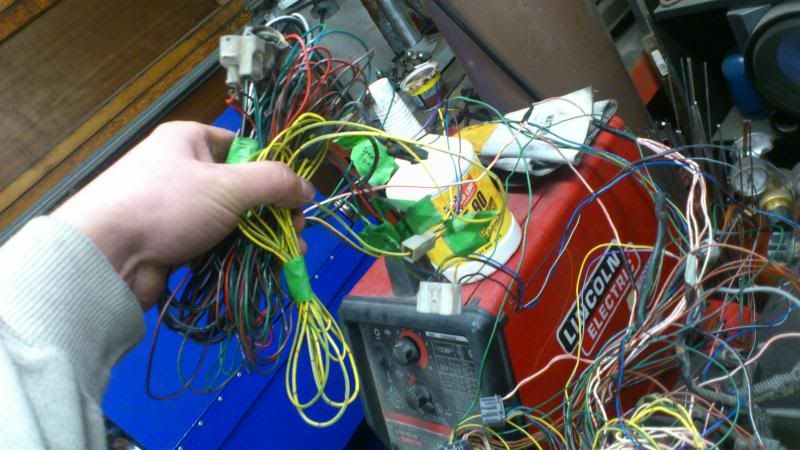

pics

shave down the race with a bread knife

wire wheel and bit of well it's in the pic

what is this

tapping the lower control arm mount

grooved busing so it can be lubed at at time

installed

good old bread knife

drilling out rubber

monkey wrench pulls the race out

used 12 gauge wire at frist it failed so I got glass cutting wire worth a try lol

welded up sections for grease fittings

tapped

installed

push have been channnled

well it's beer time boys have a good one