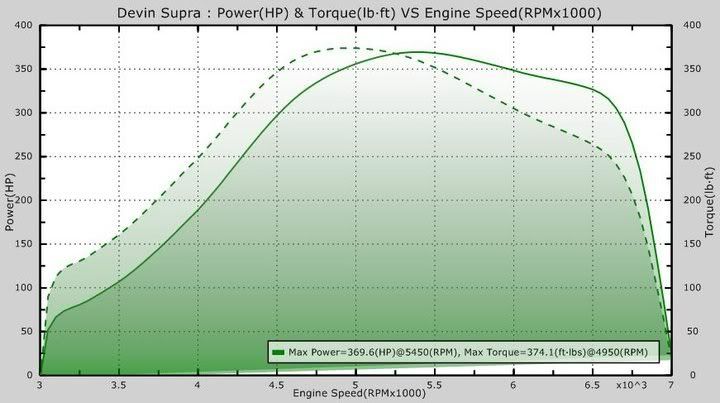

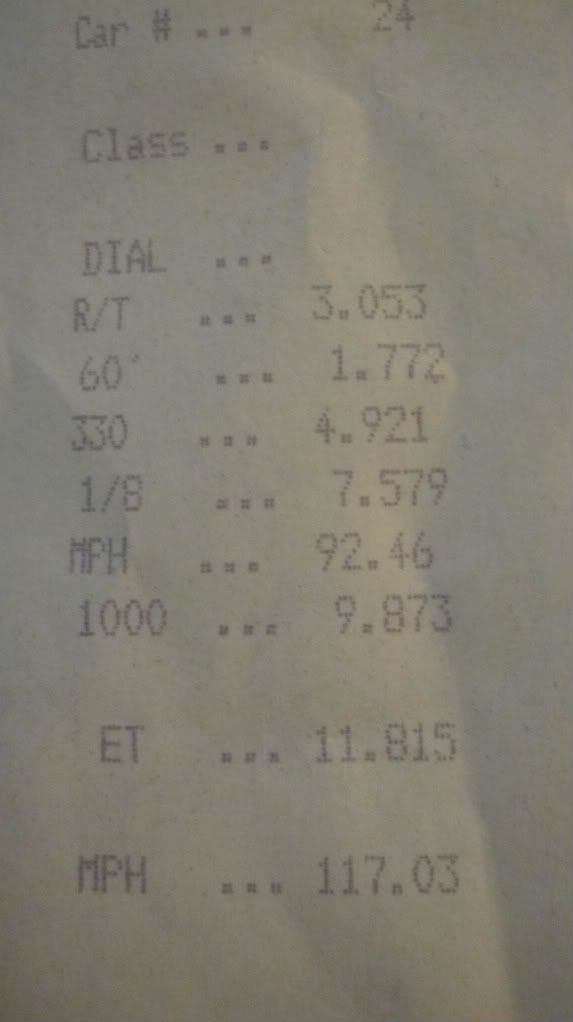

Well thought I would do a big update. Few more runs on the dyno and was able to squeeze 420WHP out of it. Threw on the slicks and headed to the drag strip. Did 11.81@ 117. Made 18 runs that night and blew the felpro head gasket hard core. It egg shaped all 6 cylinders.

Got the car towed back to the shop and pulled the head off.

Original plan was to check and clean the block, re deck the head and put on a HKS metal head gasket with new ARP head studs. Cleaned the old gasket material off the block and ended up block was pitted and was not going to seal on a metal head gasket most likely. So I pulled the motor and ripped it down to a bare block to be decked and honed. Full rebuild as follows

Deck Head, Check valve's/seats, replace valve seals

Deck Block and Power hone

All oil and coolant passages will be cleaned out in block

All new expansion plugs

Re use pistons and Rods

Clevite 77 STD Thrust, rod, and main bearings (old 153k mile old bearings looked great, could get away with reusing them but going to replace them anyways.

NPR Rings

OEM Aisin Oil Pump/pick up

OEM Toyota Timing Belt

Front/rear main seals

All Gaskets

HKS Metal Head gasket

ARP Head studs

The machine work will be done by my brother and I at Accurate Performance Machine here where Dana Westeovers Intake Manifolds were flow bench tested. Whole motor will be built and blueprinted by me as well.

Got the motor prepped for the machine work on Monday. All expansion plugs knocked out, All gaskets already removed, Front cover bolted on to be decked with block, All oil and coolant galley plugs have been removed, All thats left is to pull the dowel pins out of the block for the resurface. There's a nifty tool for that at the machine shop.

Thanks,

Devin LeBlanc