cuel said:As far as the bmep, that motor would need to run a lower rpm shift point? Would a higher compression ratio help with that? Would it be possible to tune the motor in such a fashion as to bring the peak torque point into a safer rpm range?

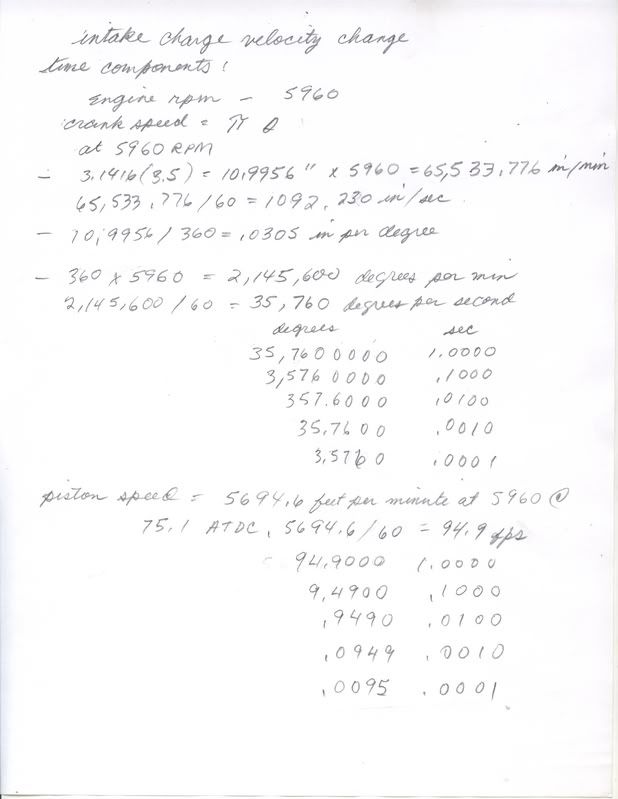

Shift point is determined by gearing, but it would need to run a lower redline than a larger r/s motor could run before the pistons would effectively outrun the flame, though port design, piston design, manifold design etc all play heavily into the burn characteristics, too much to explain here.

Higher compression, no, actually an engine tolerates compression more at higher rpm because there isn't as much time per revolution for the rapidly rising pressure to affect the rest of the intake charge. (also why short rods are a mixed blessing)

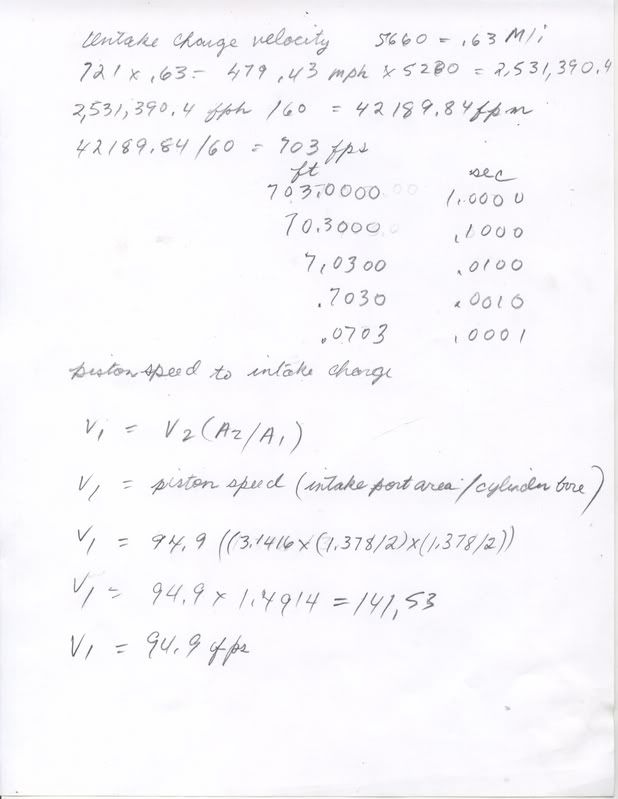

As for bringing peak torque down in the rpm range, yes it is doable, it would involve reshaping and shrinking the ports (optimal), long runner intake manifold and custom stepped header. Retiming the cams as well (advancing). Anything you can do to increase velocity in the intake manifold is good so long as you remain under mach 1 at your chosen redline. Anything you can do to increase the pressure differential across the valve is beneficial so long as you can burn it.

edit: Almost forgot, ITBs are made for throttle response, that is their purpose, they are more for handling purposes then power output, though they do certainly increase output if made properly.