OK So,

-Removed the old turbo. took it apart some, although i don't know if you can see anything there.

-Removed the charge pipes from the turbo to the intercooler. Found a little bit of turbo debris there.

-Removed the intercooler, tilted towards the hot side, spilled out a bunch of compressor wheel there.

-Shook it out as much as i could. Intercooler was flushed out with water a couple times, then smoke pressure tested afterwards, looks good.

-Looked into the cold side charge pipes, found one small bit down on the lowest point. Blew out with compressed air downstream.

-Checked 3000 pipe, clean.

-Removed Oil return and feed, lined, checked for obstructions, OK

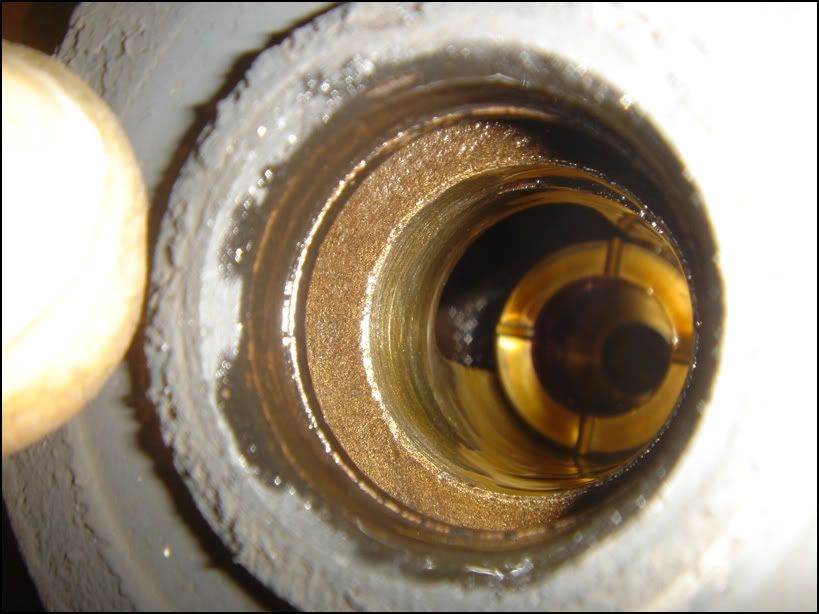

-Looked into ports with boroscope, nothing helpful to see.

-Performed synthetic oil change.

-Checking Oil Pressure.

Removed EFI fuse, cranked about 6 seconds each time, had nothing coming out the oil FEED.,

Reinstalled EFI fuse, had it turn over for a second, as soon as the RPMs bump up, i have full flow(visually) at the oil Feed.

I thought i was supposed to have oil pressure at crank, Am I?

I got the replacement stock turbo, it will go on this week if everything is well.

N/A Bay

Gotta take it apart more?

Oil feed after 2 2second runs

Return port, nothing to see..

Testing the IC

stock replacement