You better get that thing working! haha. Looks like its coming along, can't wait to see it done.

Stretch's Digidash thread

- Thread starter Stretch

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N

NDBoost

Guest

holy hell this is coming along quite well. This is definitely going to encourage more people to try this.

I think its safe to say you might be holding the first LHD Digi Dash Conversion in a Mark3 supra

I think its safe to say you might be holding the first LHD Digi Dash Conversion in a Mark3 supra

I would be interested in purchasing a full digi dash mos def.

Obviously, it wouldn't be cheap, but I think it'd be worthit.

Obviously, it wouldn't be cheap, but I think it'd be worthit.

hey man.. just a thought. if you can figre out a place to stuff the board as it is now, you could just send a bunch of tiny wires from the pin holes on the board to the pins of the screen. that way you wouldnt have to re do the WHOLE thing. you could cut a slit in the back of the plastic to slip the wires through and have the electronics mounted on the reverse side maybe?

NATAN666 said:hey man.. just a thought. if you can figre out a place to stuff the board as it is now, you could just send a bunch of tiny wires from the pin holes on the board to the pins of the screen. that way you wouldnt have to re do the WHOLE thing. you could cut a slit in the back of the plastic to slip the wires through and have the electronics mounted on the reverse side maybe?

:icon_cool

What's happening is the screen is being attached to a regular board, only as large as the screen tho so as not to take up un-necessary space. Then, we're gona run wires from the original pin holes to the new board to each corresponding hole for that particular leg. Not hard at all, just time consuming. It's called sandwiching, since the transfer board will end up sandwiched between the original board and the lcd screen. Sure, there are other ways of making this board fit into the cluster, but they are much harder, AND this way will give a factory fit/finish which will basically allow it to drop right in perfectly!

On another note, I test-fitted the smallest board today and boy was that a good idea! I had to cut away lots of the fiberglass I had put there ahahaa. It fits correctly now, but I have to re-glass some areas for it to be contained again. Oh well, I guess I was naive to think it would fit perfect the first try. Sorry no pics either, my camera lost all its juice.

eric

GAH! PICS OR BAN!!Stretch said:Sorry no pics either, my camera lost all its juice.

eric

:biglaugh:

Just messin, but pics would be appreceated!

Wow... all this effort going into the conversion... makes me wish I had a digital dash!!

Oh... wait... :biglaugh: :biglaugh: :biglaugh:

Oh... wait... :biglaugh: :biglaugh: :biglaugh:

Yeah, it's a hell of a lot of effort for such a small result, considering it came stock on thousands of other supras. I only wish Toyota would have made it for the LHD to begine with, then I would have just bought one from them.

eric

eric

Hold up guys, it takes time for these things. Both my dad and myself have been busy this week. Me with more work than usual, and him with work as usual :icon_razz . I'll be doing more work on it next week, so just sit tight damn it!

eric

eric

If you need an extra one let me know. I had planned on this awhile ago but another post on here changed my mind....

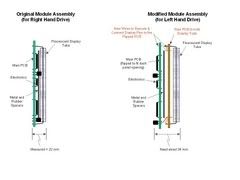

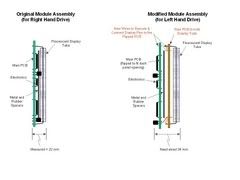

Here's a weekend update for you guys. I got a single pic. It's the diagram showing the side view of the old circuit board and the new design so that I can fit it correctly into the right side of the dash. I only gain 12 millimetres during the conversion on this side, so it'll be incredibly easier compared to the left side where i had to add a couple inches ahahaa. On with the pic!

eric

eric

Last edited: