Ridiculous 1000HP 7M Street MK3 Build

- Thread starter NegativeGeForce

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

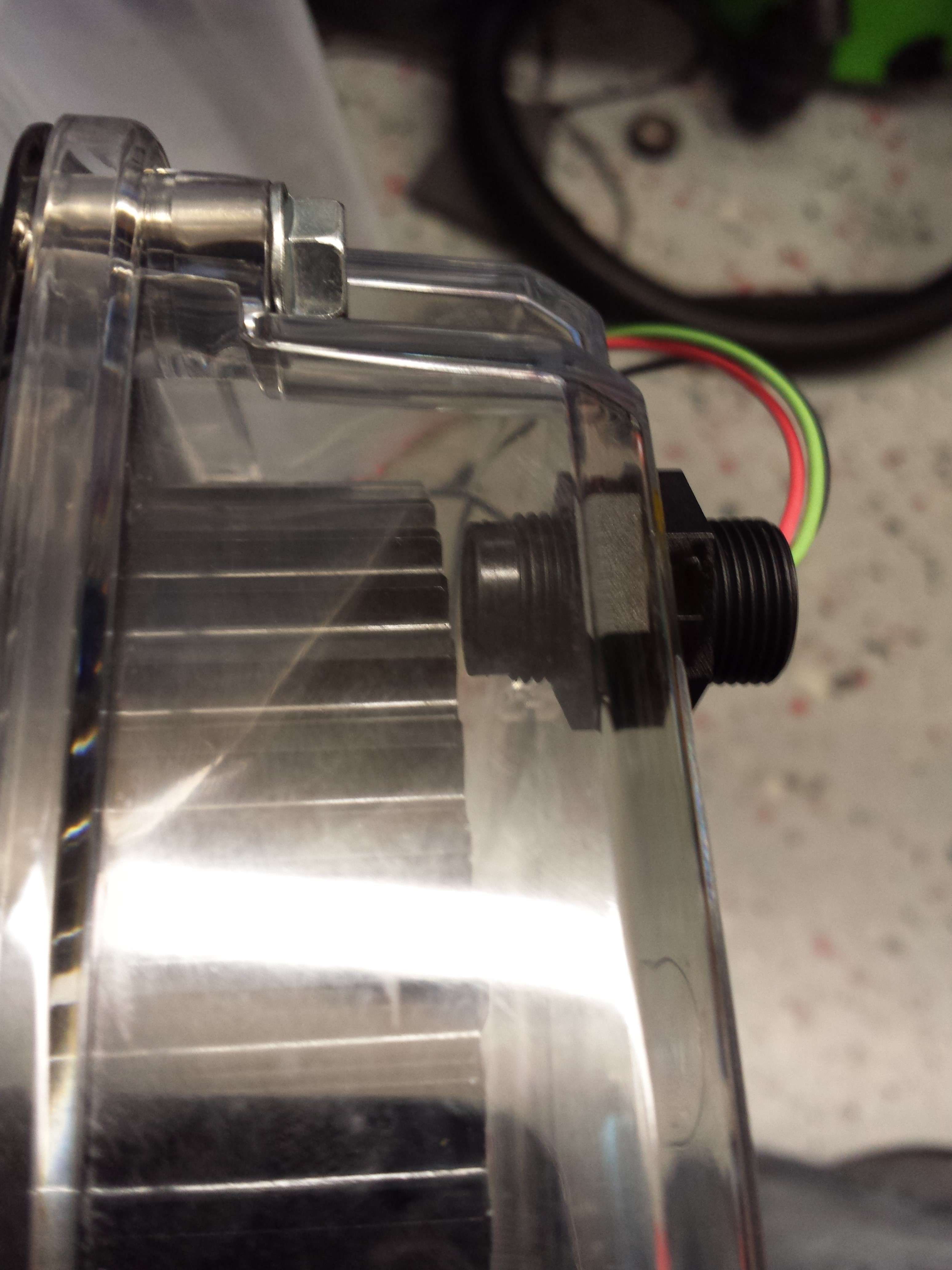

Since you have a handy Tig shop at your dispense, I dont know how many people have had this problem.. But my AN fittings on my valvecovers came loose.. and started spitting oil all over my enginebay during boost.. :-0 So I am having to get those tigged on next go around. Loving the Borg Warner. I just got a billet S366 myself. I also have JE pistons but didn't plan on going to 272 or 282's surprised the you had interference their. did you just use 2j COP? I have is300 batch fire. and I will probably be upgrade to LQ9's as their the best Bang for you buck besides add an HKS DLI or twin power or something. Looking good!

Are your fittings npt? Im using -8 oring straight fittings for my valve covers. I have 4 threads or so but with the oring I just need to snug them. I think the oring or npt fittings just look cleaner than welded.

Yep the bw turbos are the tits. I just have the cheap cast s366 cost me almost nothing for such a high quality turbo as they are.

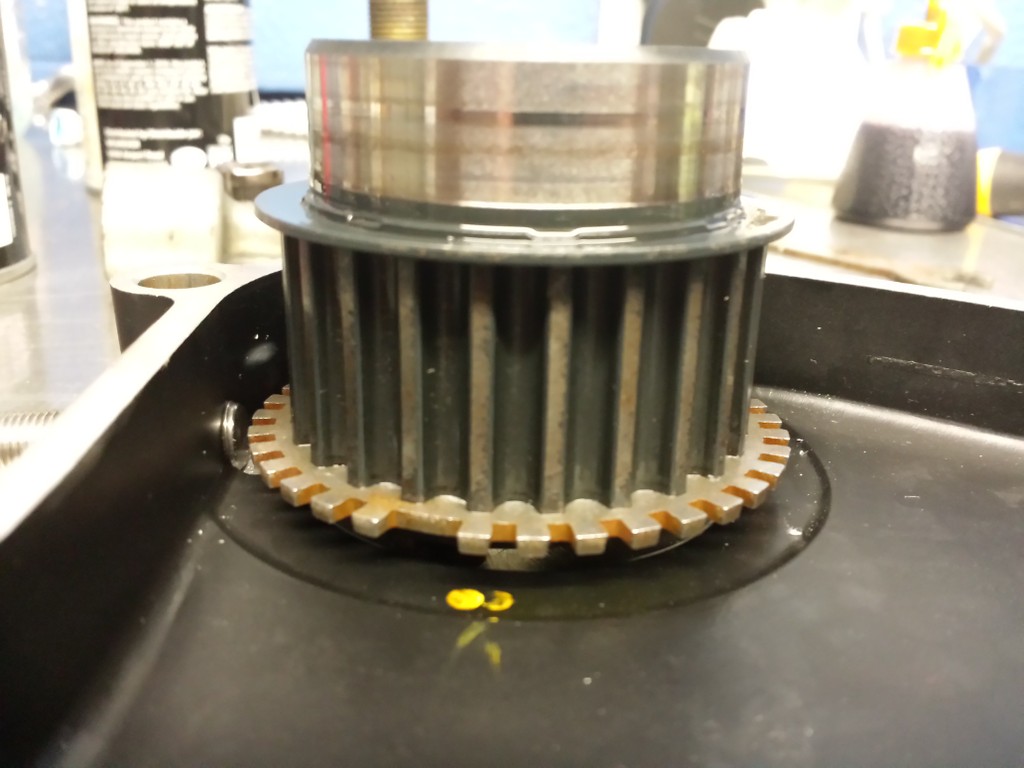

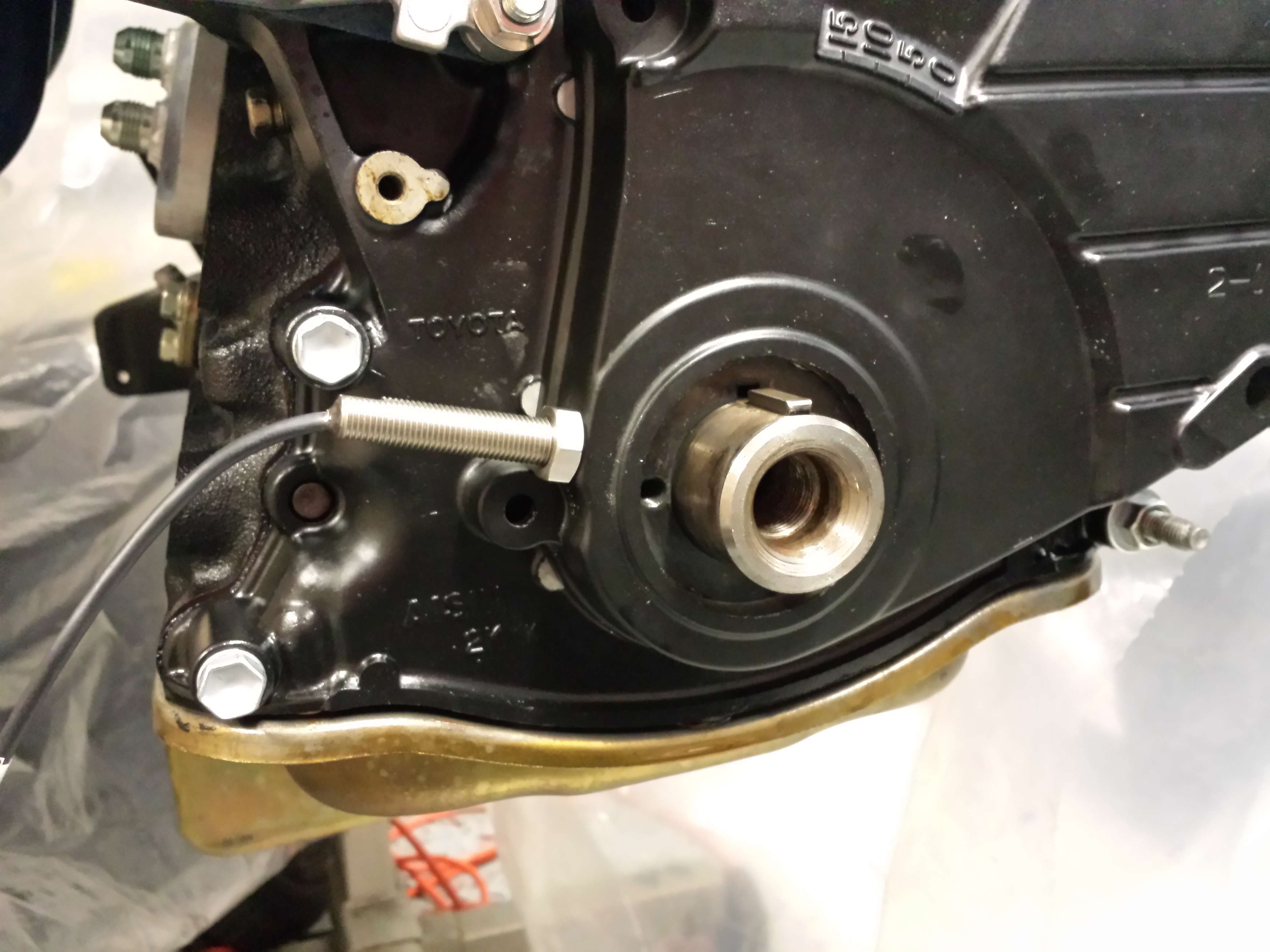

The valves almost clear with the 8.6mm lift. My motor would probably be non interference if I didn't take soo much off the head. Not a big deal. I've got the 5m oil pump gear and gates tbelt.

Using 1zz coils on Albert Meade's bracket. Gonna be running sequential ignition on a haltech elite. Decided proefi wasn't for me. I really like how haltech has so many can modules to extend it. Their software is way way way more sophisticated than proefi. I tried both. I'm a software dev for 15 years so I know these things.

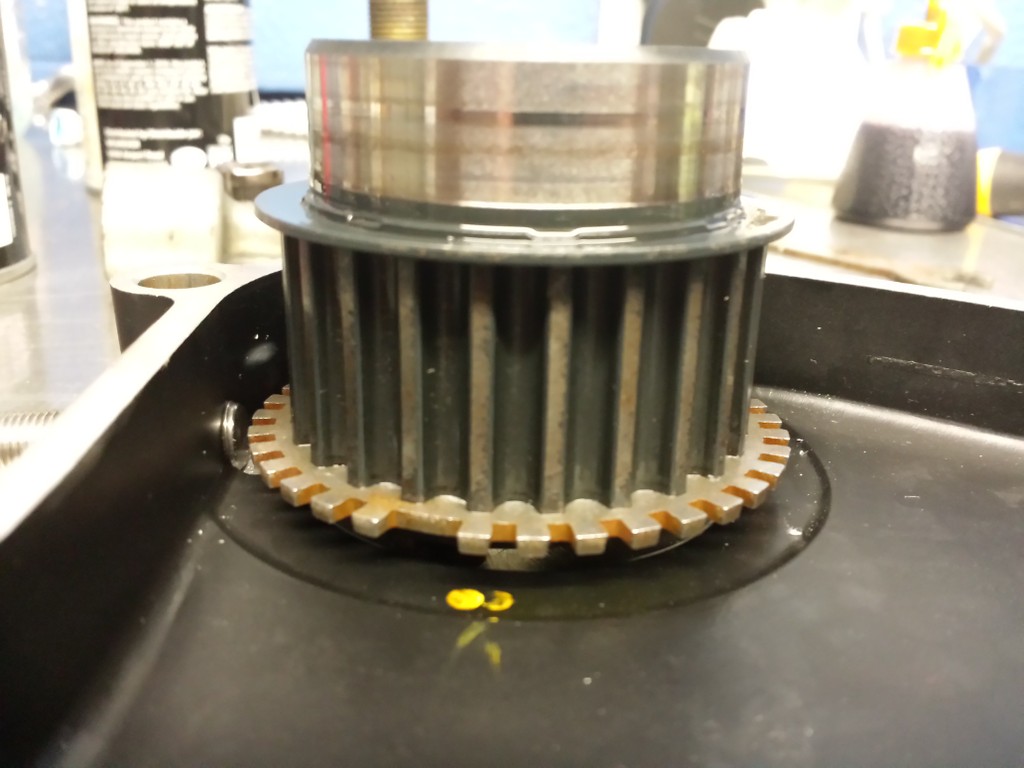

I'm still fabbing up the trigger wheel. It's similar to what Albert Meade did for Steven Reedholm. I'm just gonna use the cps as the #1 trigger.

Havent made much other progress really I've been busy with other crap. I am still waiting on my trans from jacks. I've been waiting for almost 4 months. Ugh.

should get ramped up on this shit again once my trans comes in and I get my haltech elite.

Sent from my SPH-L720 using Tapatalk

Yep the bw turbos are the tits. I just have the cheap cast s366 cost me almost nothing for such a high quality turbo as they are.

The valves almost clear with the 8.6mm lift. My motor would probably be non interference if I didn't take soo much off the head. Not a big deal. I've got the 5m oil pump gear and gates tbelt.

Using 1zz coils on Albert Meade's bracket. Gonna be running sequential ignition on a haltech elite. Decided proefi wasn't for me. I really like how haltech has so many can modules to extend it. Their software is way way way more sophisticated than proefi. I tried both. I'm a software dev for 15 years so I know these things.

I'm still fabbing up the trigger wheel. It's similar to what Albert Meade did for Steven Reedholm. I'm just gonna use the cps as the #1 trigger.

Havent made much other progress really I've been busy with other crap. I am still waiting on my trans from jacks. I've been waiting for almost 4 months. Ugh.

should get ramped up on this shit again once my trans comes in and I get my haltech elite.

Sent from my SPH-L720 using Tapatalk

NegativeGeForce;2011341 said:The valves almost clear with the 8.6mm lift. My motor would probably be non interference if I didn't take soo much off the head. Not a big deal. I've got the 5m oil pump gear and gates tbelt.

I also have big lift cam. I'm pretty sure I've discussed it with you on Facebook, my real name is Reynald.

What year is the 5M pulley, I'm thinking it is important.

Cross reference brang me there:

08/1981-11/1985 TOYOTA CELICA AA63,TA60,SA63,RA6*,MA61 13-04: TIMING BELT

08/1984-07/1988 TOYOTA CRESSIDA YX70,RX7*,GX71,MX7*,LX7* 13-02: CAMSHAFT & VALVE

08/1983-07/1987 TOYOTA CROWN YS120,MS12*,LS120 13-02: CAMSHAFT & VALVE

We talked about single vs dual springs i think but not about cams. You have the TRD cams with 10.x lift right? Unless u get custom pistons with some deep valve pockets it will definitely be interference. It's not a big deal really. Most race motors are Interference.

No idea what year the 5m gear I have it is. From what I've seen in the epc for the 5m motor there's only one variation of the gear.

Sent from my SPH-L720 using Tapatalk

No idea what year the 5m gear I have it is. From what I've seen in the epc for the 5m motor there's only one variation of the gear.

Sent from my SPH-L720 using Tapatalk

NegativeGeForce;2011357 said:We talked about single vs dual springs i think but not about cams. You have the TRD cams with 10.x lift right? Unless u get custom pistons with some deep valve pockets it will definitely be interference. It's not a big deal really. Most race motors are Interference.

No idea what year the 5m gear I have it is. From what I've seen in the epc for the 5m motor there's only one variation of the gear.

Sent from my SPH-L720 using Tapatalk

I have TRD cams with 10.8 lift you are right. I don't matter interference, European cars are, and I know timing belt is important

I think there was a variation in 1983 for pulley, I probably missread

Envoyé de mon Nexus 5 en utilisant Tapatalk

They were straight -6 followed by some 90s to a Can, then to the turbo intake. not sure how they ever got stripped. I guess I could try tapping them for -8 and the oring trick. but I feel like I wont get away from the issue unless I just make it permanent. I hate redoing things over and over again. I like overkillNegativeGeForce;2011341 said:Are your fittings npt? Im using -8 oring straight fittings for my valve covers. I have 4 threads or so but with the oring I just need to snug them. I think the oring or npt fittings just look cleaner than welded.

I would prefer not to weld them but at this point I never liked stock cam covers in the first place so I'll just wrinkle coat them and get the car running before I worry about custom covers.

The best Setup IMHO I ever saw was the PCV routed to the exhaust. This little guy. and hook it up behind the 02 as to not mess up the readings.. connecting both lines to a single line running to this to simplify the setup.. all ran behind the head to hide it more.

The 5m had 2 diffrent timing belts so my guess is 84 and 85 is the one you are after but I have scene a 85 witha 7mge one sooo not sure maybe its only one year or the one I saw was just swapped on

Yea evac pcv is probably the best so long as you're running an open exhaust with no cats or mufflers. I will probably run evac.

Sent from my SPH-L720 using Tapatalk

Sent from my SPH-L720 using Tapatalk

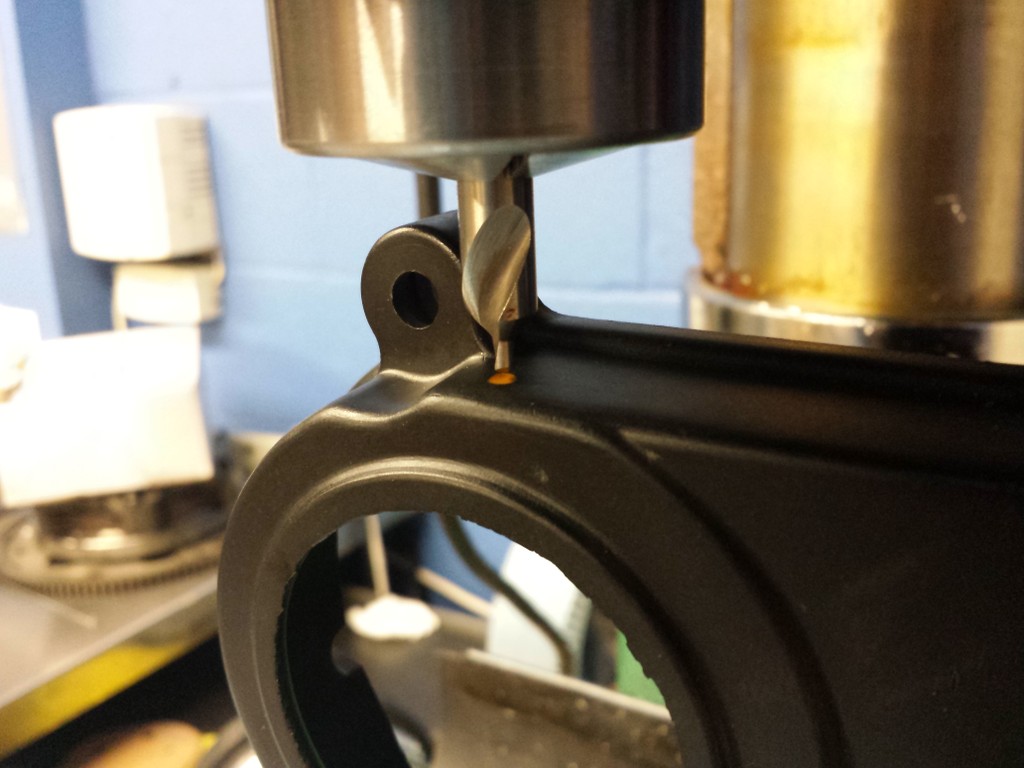

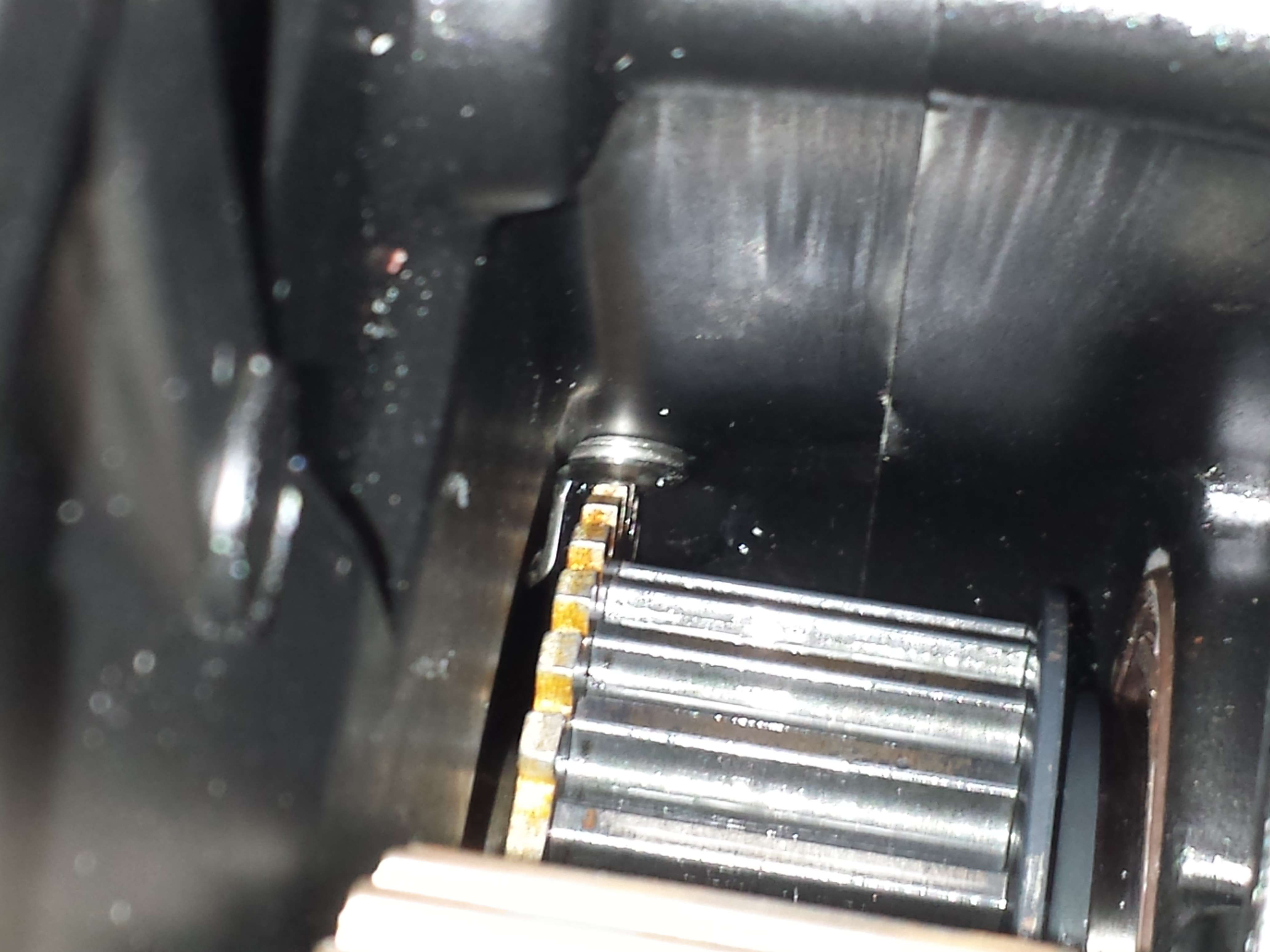

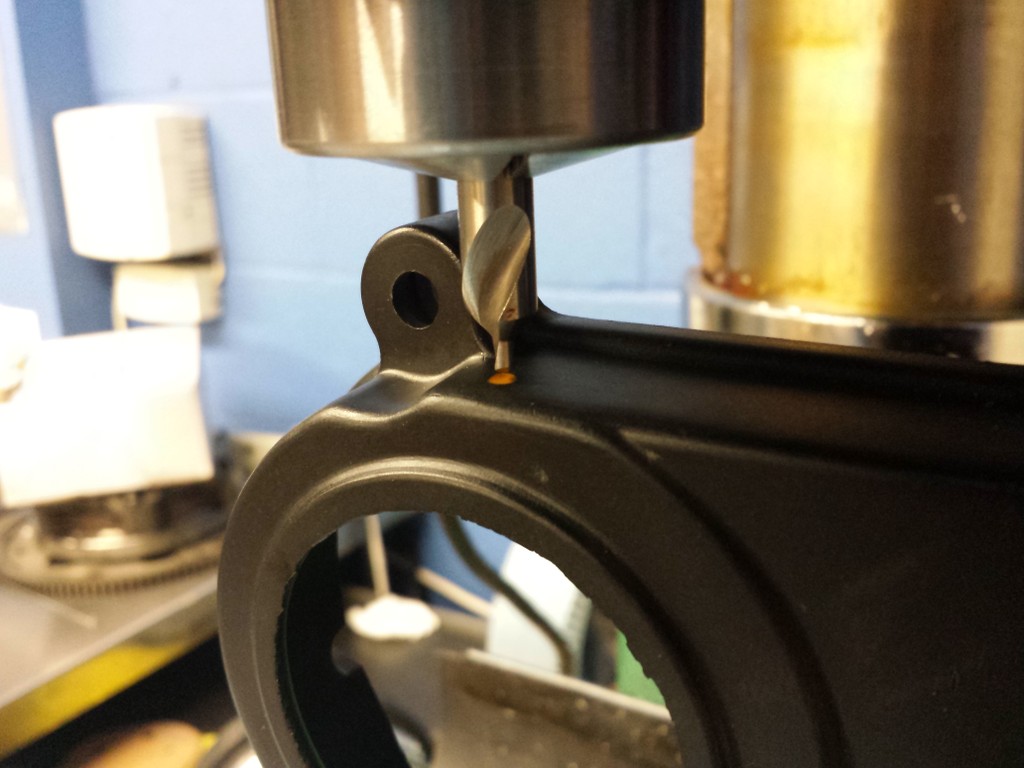

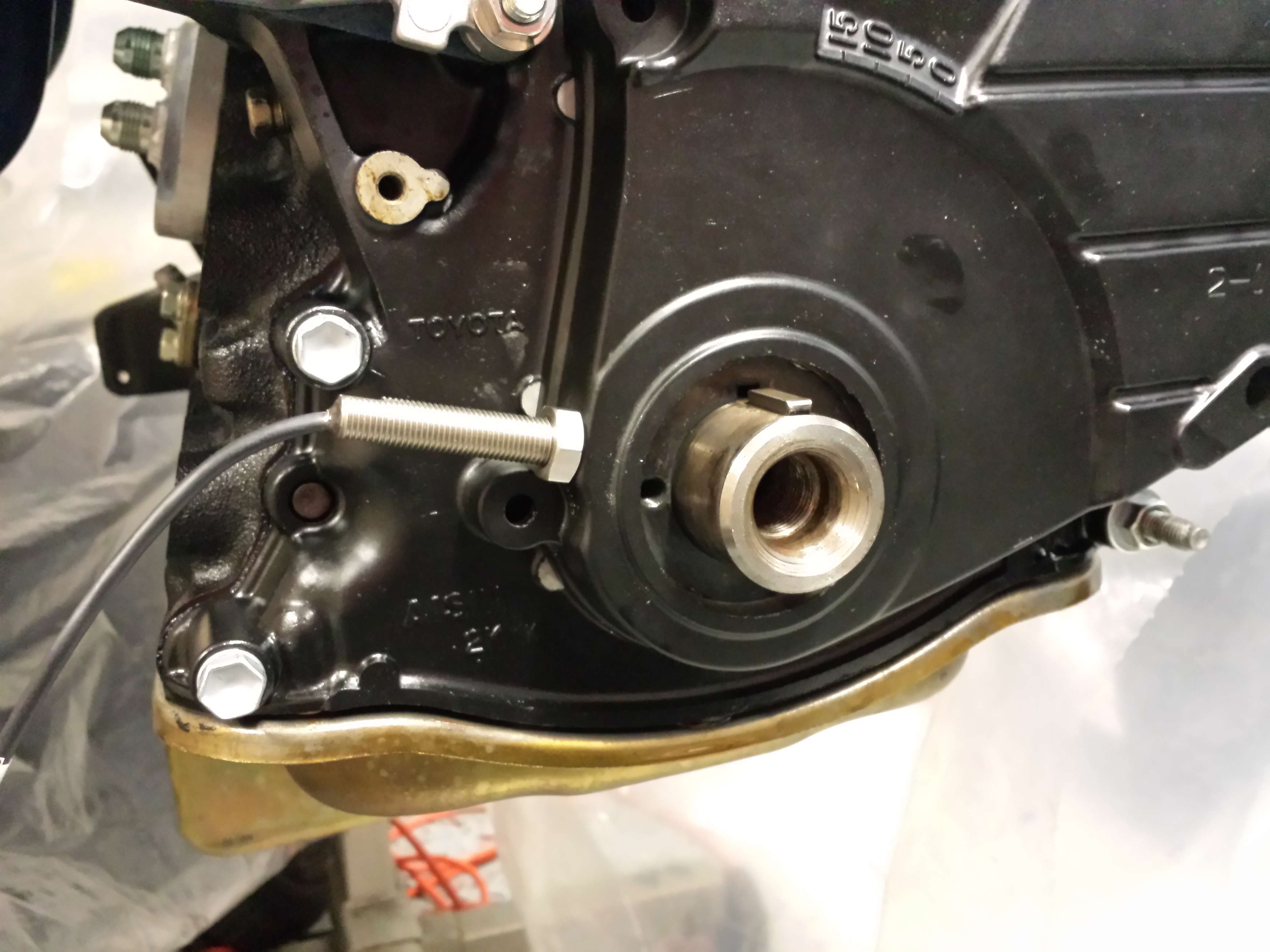

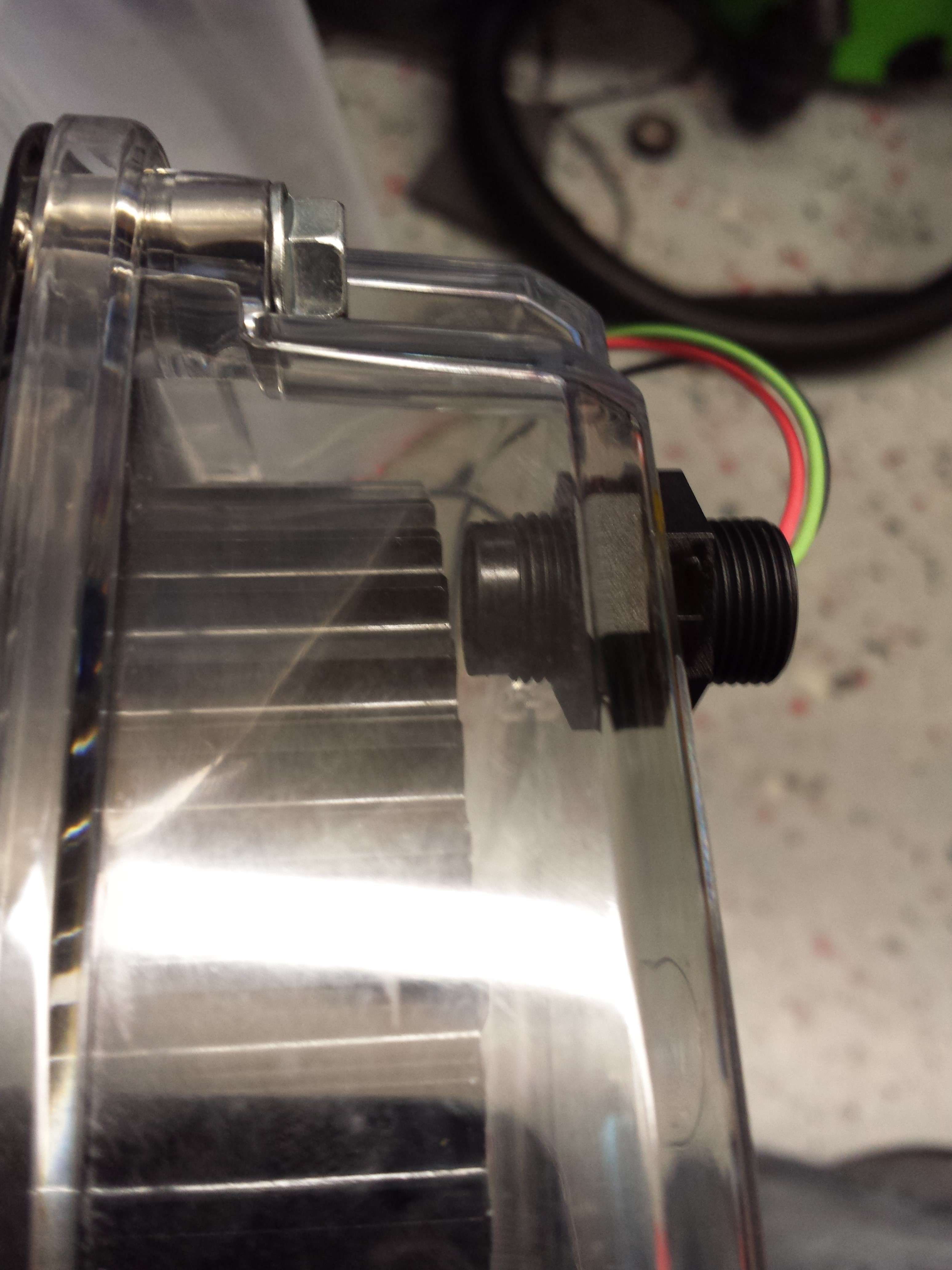

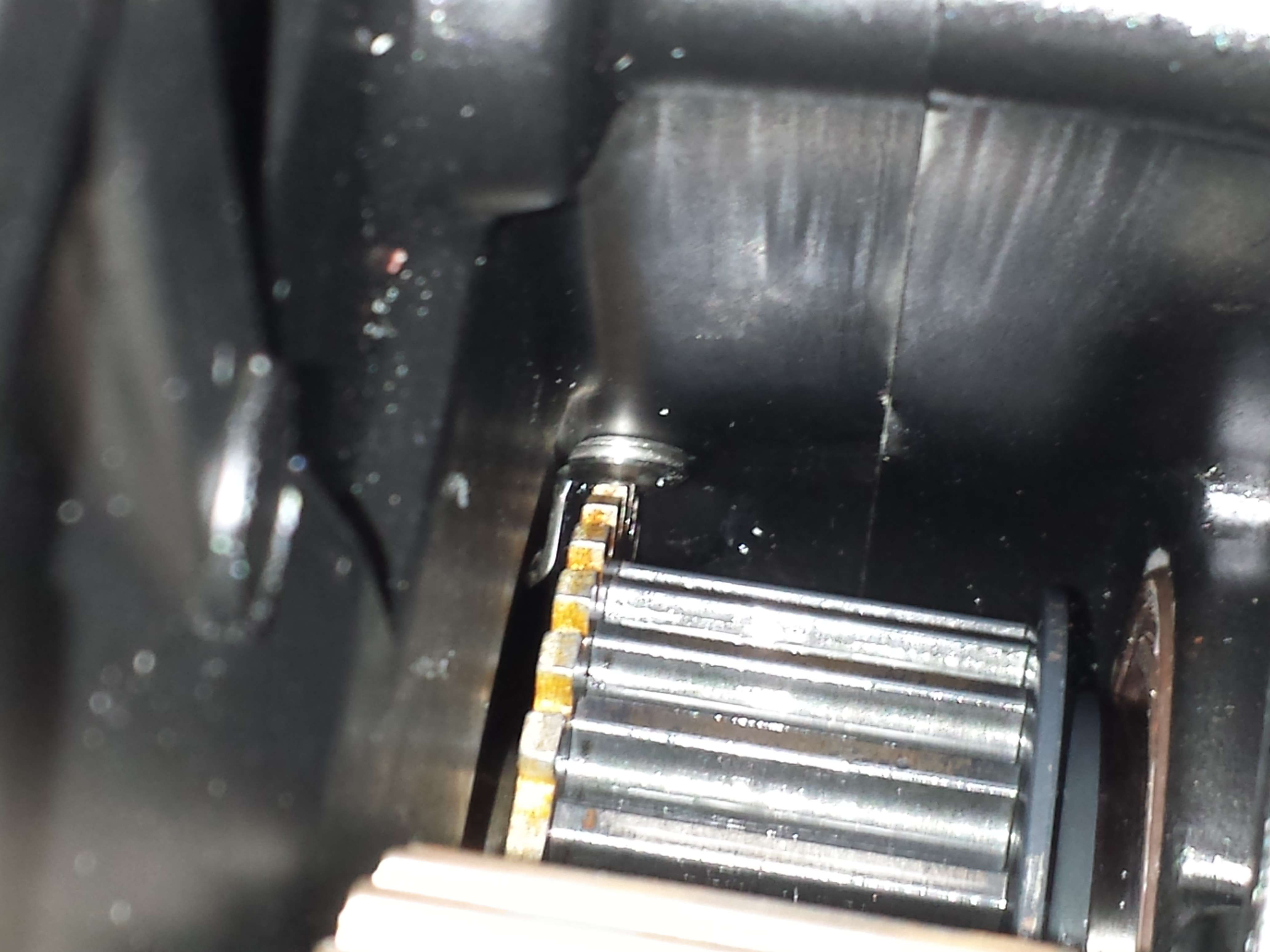

Installed crank trigger and cam sync sensors. Also, I got tired of waiting for the Haltech Elite to come out so I ended up going with the ProEFI 128 since I found a good deal.

Hopefully it wont be much longer till this thing fires up. Before end of this year *shakes fist*

Hopefully it wont be much longer till this thing fires up. Before end of this year *shakes fist*

Have you checked the output from your crank angle prox? The O.D. looks close to the aluminum timing cover, and may give a false positive. There is an area around the O.D. that the sensor can still pick up even though it is not in front of the sensor face. I see you notched some material and was just checking that you took enough out. It would suck to have to disassemble it to take out more material.

Yea i tested the wheel with an oscilloscope and also rotated the crank a few times. It makes a really clean signal.

Sent from my SPH-L720 using Tapatalk

Sent from my SPH-L720 using Tapatalk