Well , some words about the oem speedometer issue...

Only sean has done it work and maybe another one guy using the mk4 speedometer. I don't have any info about that and they didn't make a thread about it.

True is we can do only two things :

1) Going with the mk4 Supra speedo electronic gauge and send 3 wires to the V160 speedo sensor and wire them up.

2) Make it work mechanically

About the 1st route:

We must get a JZA80 speedo gauge cluster and use the speedo gauge and it's electronics. Good thing is that we will have a speedometer finally.

But that will not do the complete work. What I mean is, that we will not have a speed sensor signal so nothing will work on the car that uses the speed

sensor (pink wire) like Car ECU, TEMS, ABS, Cruise control, PPS, Super monitor, etc.

And we are gonna doom the car! What I mean? We will not have a trip meter and more important NO MILLAGE METER OF THE CAR, since we swapped out

the mk3 speedo gauge. Don't forget that the mk3 unit has them incorporated inside the gauge. And we will loose the handbrake light/low brake fluid warning light,

the, airbag warning light, and seat belt warning light. In Europe we have the handbrake warning, rear fog lights warning, and the hazzard warning lights.

BECAUSE the mk4 speedo sensor sends a wire with a uncorrected wave signal to the digital trip meter housing which it needs to produce the speed sensor signal

the famous pink wire. And from there to distribute the signal to the ECU, ABS, Traction control, Cruise, etc.

So if we go with this route we will need more things to get , to wire, etc. and where to install the mk4 digital trip meter ? That's not a small device, and it won't fit in the mk3 gauge cluster housing..so only option is option No.2 ,run the mechanical mk3 stock speedometer driven cable.

AND THE PROJECT HAS JUST STARTED!

- I found out that the mk3 and mk4 speedo gear housing are interchangeable, same OD. and will fit fine.

So,we will need the mk3 mechanical speedo housing to put it inside the V160 transmission so we can make the transmission's speedo sensor to work mechanically

like the mk3 Supra.

- We can not use the mk3 speedo gear though since it has different teeth pattern 33:11. This is written on the small oem white gear that goes inside the trans.

We will need to swap the V160 gear which is 31:12 that will mate perfectly with the V160 since it is it's factory part.

I did that and it has the same OD shaft size and safety lock pin position but......it is too short. The V160 shaft is shorter than the R154 by about half an inch.

We have to make an adapter to lengthen the shaft.

Here is the actual parts, you can clearly see the V160 gear shaft being much shorter than the R154.

And when I put the V160 gear inside it fits just fine and spins like the R154 gear...but it is shorter.

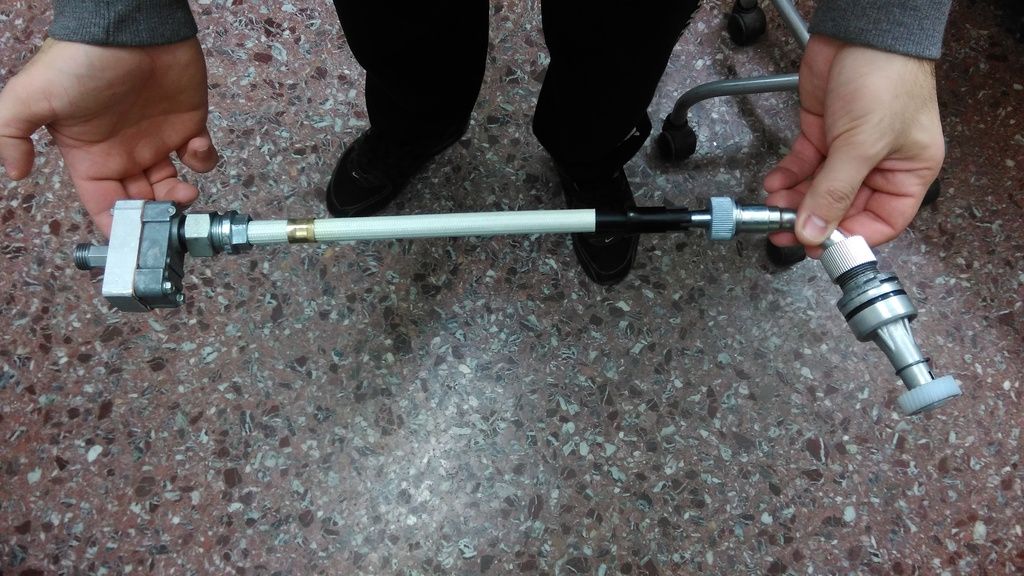

So, I had to make an adapter. A male one that will fit the V160 gear shaft on one side and a female one on the other side that will fit the oem

mk3 speedo cable. This is what I did. Cut the old R154 rear shaft with the female housing and weld it with a male pin from an old mk3 No.1 speedo cable

the short one. The No.2 is the long one that goes directly to the gauge cluster in the speedometer gauge of the mk3.

Male side that will go inside the V160 shaft gear.

Female side that will go into the male pin of the no.2 speedo cable.

And will look like that ,the small adapter length is 36mm , but I think 35mm will be closest to oem, and I will trim 1mm off.

Now we have a good proper working speedo gear which works with the V160 trans and will produce mechanical movement to the mk3 oem driven

speedometer cable !