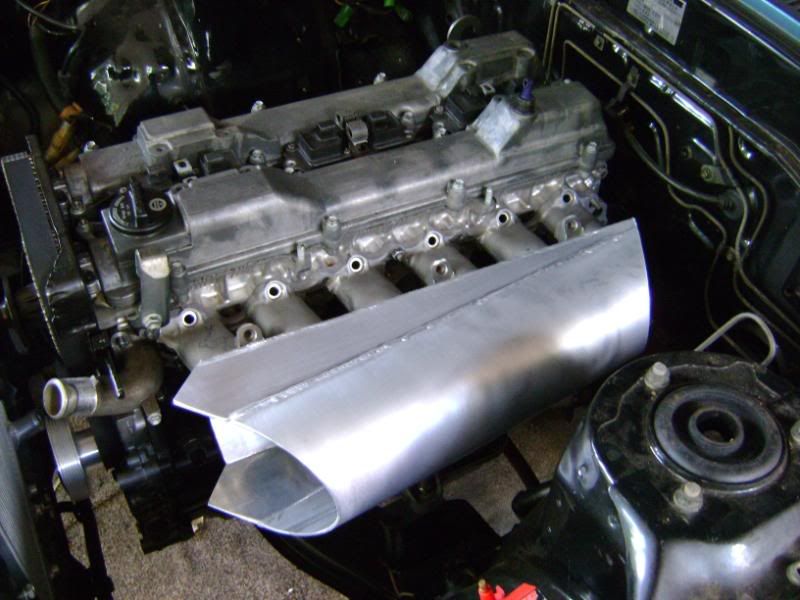

I took the engine today to the machine shop to align bore the mains for the main studs, decked the block, bore + hone to 86.5mm with torque plate and decked the head. i cant wait for the (OUCH bill) but i really cant wait to get the engine back to start puting it together!

Also here is the trany i am going to use.

I am hoping this clutch setup will hold the disc is a special sintered iron unit sliper disc and the preassure plate is a clutch master unit with a lot of preassure i will install it straight up first and if it sticks too much i will shim the preassure plate to achive the amount of slipery i need to get the job done the good thing about this is i dont have to take the trany off to shim it

the parts i ordered from Marlin Crawler to internally bulletproofing my R154 trany these parts are custom made by Marlin Crawler to beef up the 'R' Series Tranys take a look!

this is the bearing retainer the factory one is made out of aluminum and flex on high HP levels making a gap betwine the bearing and the thrust washer making the trust washer fail and brake missaligning the gears creating failure in the trany! this one is made out of Tool Steel with grade 8 bolts

And this is the trust washer that is made out of cast iron from factory very weak this one is made out of Chorme Moly and is billet from a solid pice!

With these parts the R154 becomes Virtually BULLET PROOF!I HOPE:facesjump