doh! pimp's re-BUILD

- Thread starter pimptrizkit

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

agreedloki2043 said:i want some updates you tard!!!

how are things coming james?!

move you ass and show some pictures!!! lol. come help me pull my engine damn it!  im having problems especially when i get home every day at 6 aand its pitch black out cant see shit!

im having problems especially when i get home every day at 6 aand its pitch black out cant see shit!

dont you know i go to work at 5?

any ways, friday i could probaly give you a hand, if not i'll check my schedual.

any ways, friday i could probaly give you a hand, if not i'll check my schedual.

friday is nice. dont have to work on friday... but i still wanna see some updates.. and ide like to see that r154 in and not that poopy auto.

Are you really putting that cracked block in your car? It's all up to you, but I wouldn't let that block anywhere near a running car, especially with the added stress from ARP head bolts or studs. The oil pump drive situation sounds sketchy as well. It's always when you want to get things done that things get jacked up.

that is a very common crack. he just needs to loctite the block at that spot and he should be good. I actually think its the msot common crack on or cars.Zach said:Are you really putting that cracked block in your car? It's all up to you, but I wouldn't let that block anywhere near a running car, especially with the added stress from ARP head bolts or studs. The oil pump drive situation sounds sketchy as well. It's always when you want to get things done that things get jacked up.

his block was also cracked when we bought the motor from japan. It ran great and boosted to 14-15lbs no problem until he blew the stock hg.

andd.. i'm not too big of a drinker unless its 4th of july :biglaugh:

andd.. i'm not too big of a drinker unless its 4th of july :biglaugh:

i got my bases covered guys, dont fret to much..

finaly got the oil pump drive bearings figured out, turns out toyota either shipped the wrong bearings, or their unfinished. the first set of aftermarket bearings went right in, no problem,

tip 4 bearing installtion is to make sure the block bores are clean, quick hone if needed,, burr, or rust. then lube the bearing on the out side with oil or a liquid wax, and take your time. for sqaure!

any ways, got the oil galleries plugged up, put the filter housing on, pressure sender, front main and pump shaft seal in, timming cover is on, new woodruff keys, crank sproket on, motor mounts on,

as far as the head went.

i installed the studs first, and used slicone on all of the studs that contacted the head, and got them fairly snug. wipped off the access sealer, and then took brake clean to ensure the head & block were oil and contaminite free.

i also set the mhg on, and decided that i was going to remove the brass retainer on the front right of the mhg, due to block contact, the head doesn't hit here, but i felt it was poor placement and i just want the best seal as possible.

rigt now the head is sitting on the block, and i found arp was 4 washers short when they sent out the main studs, so i used the ones from the head, shorting me here.

any ways, all i have left is to put the hard water lines on, bolt the turbo back on, and the intake mani, along with timming belt, front timming cover, rear main seal, & oil pan, and i should be looking to be outting this sucka back in.

any ways, here's to great cell phone pics!

finaly got the oil pump drive bearings figured out, turns out toyota either shipped the wrong bearings, or their unfinished. the first set of aftermarket bearings went right in, no problem,

tip 4 bearing installtion is to make sure the block bores are clean, quick hone if needed,, burr, or rust. then lube the bearing on the out side with oil or a liquid wax, and take your time. for sqaure!

any ways, got the oil galleries plugged up, put the filter housing on, pressure sender, front main and pump shaft seal in, timming cover is on, new woodruff keys, crank sproket on, motor mounts on,

as far as the head went.

i installed the studs first, and used slicone on all of the studs that contacted the head, and got them fairly snug. wipped off the access sealer, and then took brake clean to ensure the head & block were oil and contaminite free.

i also set the mhg on, and decided that i was going to remove the brass retainer on the front right of the mhg, due to block contact, the head doesn't hit here, but i felt it was poor placement and i just want the best seal as possible.

rigt now the head is sitting on the block, and i found arp was 4 washers short when they sent out the main studs, so i used the ones from the head, shorting me here.

any ways, all i have left is to put the hard water lines on, bolt the turbo back on, and the intake mani, along with timming belt, front timming cover, rear main seal, & oil pan, and i should be looking to be outting this sucka back in.

any ways, here's to great cell phone pics!

jeesh, your phone takes some sweet pictures. lol, any ways.. lookin good jim, aslong as you find all of parts to put the motor back in *you better have labeled them..*.. it should be a straight 1 hour drop in and another 2-3 hours bolting up peices.. and probably 4 hours to get that damn turbo oil line in right :3d_frown:

lol joe,

nah the turbo and all the good stuff will be put on correctly before the motor is installed, and im surprized about the phone pics too!

any ways, im looking to have the motor dropped in roughly under 2 hours.

but i still need a down pipe...

nah the turbo and all the good stuff will be put on correctly before the motor is installed, and im surprized about the phone pics too!

any ways, im looking to have the motor dropped in roughly under 2 hours.

but i still need a down pipe...

i got a nice stock DP for ya! free!! lol. :biglaugh: top notch quallity,ill even throw in the stock kitty cat for ya.:naughty:... cant wait to get my DDP

nah ive been looking at this nice bic, down pipe, just have to wait till next paycheck to buy it!

okay. btw i got your message and i'll have to buy oil on wednesday when i get paid.. if i got your message earlier i would have, but i put $200 this week into my motor payment. I only owe $400 more! :biglaugh: should get it paid off this month and then i can start saving for other stuff..

well, i do have to say, some thing is still missing!!!!!

i have left the pan off, because where going to do a pressurized oil test, and check for any thing abnormal, and make sure we get oil to the head, and so on.

might be interesting to see at what psi the oil squirters open up??

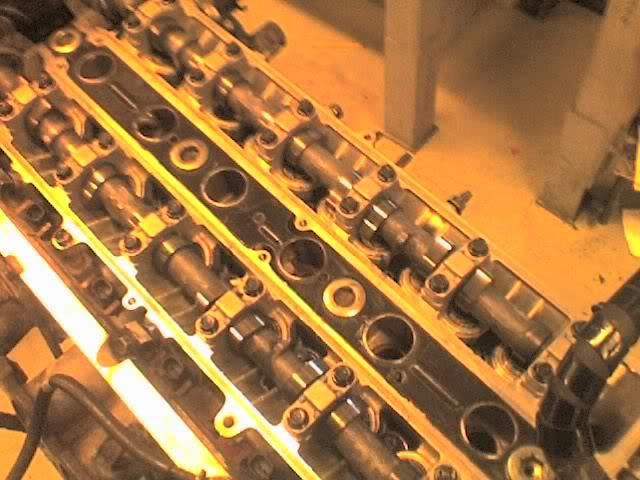

good o'l n/a cam's!

now in these pictures i was setting base timming,

witht the next two, this is where the cps should be, with base timming at 12* or more

and in the second pic, you can tell it's more, im having a bit of a issue putting it back to spec, i was happy with it cause i knew it was in time, but my instructor wanted the cps cover off to look inside, then ofcourse he said it wasn't timed correctly, eh.. so out came the cps.. any tip's ?

and im almost thinking the new woodruff keys im using are causing this problem because of where the timming marks on the balencer sit, i also noticed the balencer has some play in it when the bolt is no tight, which i have a gut feeling is a no no, im gona give toyota a call and check on the woodruff keys,

ninja edit~ also, in about a weeks time, i will also be going through a r154 and snaping pic's along the way, and explanning some details, so stay tunned! oh yah, also drilled out the j-tube today!

i have left the pan off, because where going to do a pressurized oil test, and check for any thing abnormal, and make sure we get oil to the head, and so on.

might be interesting to see at what psi the oil squirters open up??

good o'l n/a cam's!

now in these pictures i was setting base timming,

witht the next two, this is where the cps should be, with base timming at 12* or more

and in the second pic, you can tell it's more, im having a bit of a issue putting it back to spec, i was happy with it cause i knew it was in time, but my instructor wanted the cps cover off to look inside, then ofcourse he said it wasn't timed correctly, eh.. so out came the cps.. any tip's ?

and im almost thinking the new woodruff keys im using are causing this problem because of where the timming marks on the balencer sit, i also noticed the balencer has some play in it when the bolt is no tight, which i have a gut feeling is a no no, im gona give toyota a call and check on the woodruff keys,

ninja edit~ also, in about a weeks time, i will also be going through a r154 and snaping pic's along the way, and explanning some details, so stay tunned! oh yah, also drilled out the j-tube today!

I had almost the exact same crack between cyl 4-5 ( exhaust side) in a jdm engine I bought. The cracks had spread to the bridges in the cooling jackets on either side of the bolt hole. I used another block I had and found a small crack in it too, after machining. This must be alot more common than you'd think.

You must have some mighty balls there Pimp. I would never use that block.

You must have some mighty balls there Pimp. I would never use that block.

pimptrizkit said: