The sound in the clip sounds like a (too) low preload. Meaning the rollers can skid. This is actually a intermediate control when you set bearing preload. You will notice when this skidding sound is gone (all rollers have some tension forcing the rollers to roll) you are close to the correct preload.

Diff rebuild by "pro" not going well

- Thread starter alcyon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It thought so at first, but at higher preload it was doing the same thing. I think I might have damaged some rollers while pressing in the pinion to the companion flange the first time. After I changed to another set of new bearings and very carefully installed them, no more clicking sounds.The sound in the clip sounds like a (too) low preload. Meaning the rollers can skid. This is actually a intermediate control when you set bearing preload. You will notice when this skidding sound is gone (all rollers have some tension forcing the rollers to roll) you are close to the correct preload.

Anyway I put back the diff together, and got a good backlash, I didnt bother to re check gear pattern as the pinion depth is unchanged.

A spin test with my crank handle is smooth and no horrid sounds.

Here it is on the back seat of my mother in law's car all packed up to go home

Last night I got careless and the diff was going to fall, I had to stop it with my arm, and the exposed ring gear cut into the middle of my left arm, blood trickling.

Here it is the next day.

Gonna take another 2 days before I fit it back to the car.

Just tested the car. The good. All low speed grinding noises are gone. I have not tested for a very long distance .Now the not so good, as soon as i reach 60mkh and went up to 66kmh, there is same type of whine as the previous (4th) rebuild with the used gears, but 1/5th the loudness. It is a smooth soft high pitch whine. I dont think the gear pattern is wrong, but could be pinion preload is not high enough, as the 3rd rebuild with very high preload had no whine at the beginning. It could also be the lightly false brinelled carrier bearings, eventhough it felt smooth and spun smooth. I am stumped yet again. and getting very tired of this.

Just gonna go for light break in again. I may just tighten the pinion but a bit more next week and see if it helps. Then again maybe its just some resonance happening because of the poly subframe bushings. Other than these issues, the improvement in low speed coasting is tremendous, no grinding sound at coasting at very low speeds, which confirms that the 4th rebuild used gears were grinding each other.

I talked to my brother, so he gave me an idea.

1. Buy a used untouched GA70 GZ20 diff from japan with 9/41 gears. Take all the baseline readings off it. Install as is and test. If its better, just use it.

2. I found a post on FB on this guy here who does 1jz and 2jz swaps and there was this post that a woman made thanking him for solving her prop shaft/diff issue on her modern rwd bmw. She praised him for solving the problem she had that a few other mechanics couldnt solve. Maybe look for him and let him have a go at it.

Just gonna go for light break in again. I may just tighten the pinion but a bit more next week and see if it helps. Then again maybe its just some resonance happening because of the poly subframe bushings. Other than these issues, the improvement in low speed coasting is tremendous, no grinding sound at coasting at very low speeds, which confirms that the 4th rebuild used gears were grinding each other.

I talked to my brother, so he gave me an idea.

1. Buy a used untouched GA70 GZ20 diff from japan with 9/41 gears. Take all the baseline readings off it. Install as is and test. If its better, just use it.

2. I found a post on FB on this guy here who does 1jz and 2jz swaps and there was this post that a woman made thanking him for solving her prop shaft/diff issue on her modern rwd bmw. She praised him for solving the problem she had that a few other mechanics couldnt solve. Maybe look for him and let him have a go at it.

Last edited:

Hello everyone! It's been a while..

I just wanna say that our mk3 community is very lucky and blessed that has a guy like " Piratetip " who is very experienced in Toyota Supra differentials

and one of the best out there. I would only trust him in building a proper performance differential....like I did back in 2017 , and I am also located overseas!

I just wanna say that our mk3 community is very lucky and blessed that has a guy like " Piratetip " who is very experienced in Toyota Supra differentials

and one of the best out there. I would only trust him in building a proper performance differential....like I did back in 2017 , and I am also located overseas!

With poly bushings you WILL have a slight gear whine. You can't resolve this. The diff is mounted directly to the subframe. I went from 80a RK bushings to Superpro. This made a significant difference, especially in gear shock. As long the diff sounds smooth and you don't experience any binding in corners, you should be fine. So no rumbling of whirring noises.Just tested the car. The good. All low speed grinding noises are gone. I have not tested for a very long distance .Now the not so good, as soon as i reach 60mkh and went up to 66kmh, there is same type of whine as the previous (4th) rebuild with the used gears, but 1/5th the loudness. It is a smooth soft high pitch whine. I dont think the gear pattern is wrong, but could be pinion preload is not high enough, as the 3rd rebuild with very high preload had no whine at the beginning. It could also be the lightly false brinelled carrier bearings, eventhough it felt smooth and spun smooth. I am stumped yet again. and getting very tired of this.

Just gonna go for light break in again. I may just tighten the pinion but a bit more next week and see if it helps. Then again maybe its just some resonance happening because of the poly subframe bushings. Other than these issues, the improvement in low speed coasting is tremendous, no grinding sound at coasting at very low speeds, which confirms that the 4th rebuild used gears were grinding each other.

I talked to my brother, so he gave me an idea.

1. Buy a used untouched GA70 GZ20 diff from japan with 9/41 gears. Take all the baseline readings off it. Install as is and test. If its better, just use it.

2. I found a post on FB on this guy here who does 1jz and 2jz swaps and there was this post that a woman made thanking him for solving her prop shaft/diff issue on her modern rwd bmw. She praised him for solving the problem she had that a few other mechanics couldnt solve. Maybe look for him and let him have a go at it.

FYI, I run poly bushings all around.

There is no rear end noise is transmitted into the cabin.

Totally silent.

There is a tiny bit of transmission noise, but barely noticeable.

The MKII Supra is another story though.

No matter how you build the diff it hits a harmonic noise around 50-60mph.

Fairly common on that chassis.

On the MKIII chassis, if the diff is built properly it's silent.

There is no rear end noise is transmitted into the cabin.

Totally silent.

There is a tiny bit of transmission noise, but barely noticeable.

The MKII Supra is another story though.

No matter how you build the diff it hits a harmonic noise around 50-60mph.

Fairly common on that chassis.

On the MKIII chassis, if the diff is built properly it's silent.

I bought a air impact and will receive it soon. I am gonna tighten up the pinion nut 1/16th to 1/12 th of turn to crank up the preload. I looked at my notes between the 3rd rebuild and compare to the 4th and 5th rebuild, one major difference is the pinion preload. It was very high on the 3rd rebuild , it was tight at static but once moving it was very smooth. I had no whistle/whine at 60kmh with that 3rd build. Also on the 3rd build, the gear pattern on coast was a bit shallow and was running off the toeWith poly bushings you WILL have a slight gear whine. You can't resolve this. The diff is mounted directly to the subframe. I went from 80a RK bushings to Superpro. This made a significant difference, especially in gear shock. As long the diff sounds smooth and you don't experience any binding in corners, you should be fine. So no rumbling of whirring noises.

It could be the groaning noise I heard in the 3rd rebuild after 1000 miles is the pinion contacting the edge of the ring gear coast toe, and not a too high pinion preload as I thought Initally.

In the 4th rebuild, there was a whine-whistle and grinding sound on the same 1000 mile gearset, only difference is pinion depth was deeper, and pinion preload was lower than 3rd rebuild.

In the 5th rebuild with new gears, pinion depth is good, pinion preload low, there is no grinding just a low whistle-whine. So gonna increase preload and see if this whistle-whine goes away, before I do anything else. it could very well be that this whistling sound is the pinion bearings partially sliding on the raceways instead of rolling.

One thing I forgot to mention is the front pinion bearing shell is a little loose in the housing, since the 4th rebuild. Its not so loose that I can push out or press in the shell with my hands, but light taps on a screwdriver brought it out. It was easier to install and remove compared to the innner larger bearing shell, that took me 20 minutes of hammering in a circle with a punch to get out, and some force to press a new one in.

I do not see any evidence the front bearing shell was spinning in the housing though.

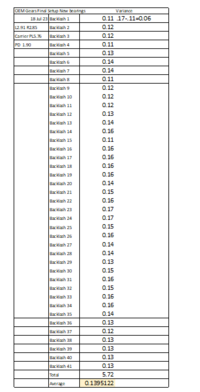

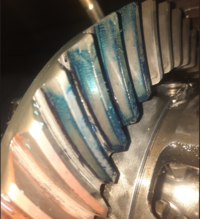

I attach a file about tapered roller bearing preloading.

Attachments

Last edited:

Well, this is the reason why the manual states two different preloads. One for new and one for used. Are you using a crush sleeve at this point? I don't see the front outer race to be a major issue if there are no signs of spinning. Probably it sets itself under preload anyway.

To set the pinion nut i made a tool to hold the flange. This way i can accurately approach the torque limit with 10Nm steps (which is about 1/8" or 3mm movement if you mark the nut/pinion with a sharpie)

To set the pinion nut i made a tool to hold the flange. This way i can accurately approach the torque limit with 10Nm steps (which is about 1/8" or 3mm movement if you mark the nut/pinion with a sharpie)

No its still Weir Eliminator with shims. Yes I have a holding tool which i made last year. Ok here is the full rundown. I got my impact and proceed to impact the hell out of that nut, and it wont budge. So I removed the diff. Checked the preload, it was basically almost 0 preload. With the diff off the car, I screwed the flange holding tool, and used a long extension to crank down on the nut. I went as much as I could which is 1/12th of turn, the preload increased, but not enough. I decide to bring the diff to my workplace that night itself(Saturday 29th) after dinner and swap out one thinner shim. After dinner I loaded all my tools and the diff to my workplace. I proceed to tear apart the diff. The oil was loaded with gunk, it was black mixed with yellow, seems to have lot of metal in the oil, not sure coming from where.Well, this is the reason why the manual states two different preloads. One for new and one for used. Are you using a crush sleeve at this point? I don't see the front outer race to be a major issue if there are no signs of spinning. Probably it sets itself under preload anyway.

To set the pinion nut i made a tool to hold the flange. This way i can accurately approach the torque limit with 10Nm steps (which is about 1/8" or 3mm movement if you mark the nut/pinion with a sharpie)

Removed the pinion, swapped one Weir 0.2mm shim to a 0.17mm shim. Re assembled the pinion, cranked down on the nut at 150ft lb, then added another 1/16th of a turn. The preload was now much higher, but i felt still not as high as the 3rd rebuild, so I cranked down a tad more till I felt I couldnt. This time I felt the pinion was stuck at first, then with some ooomph, it turned very smoothly and not notchy. I could feel the rolling resistance. It felt just like the 3rd rebuild. I check breakaway, it was more that 40inlb. At this point I dont care about the breakaway anymore. The rolling was about 7 inlb , and the best part, no fluctuation on the In lb torque wrench needle. As long I kept it moving it gave consistent reading. Staked the nut put everything back as it was. Brought back the diff.

On Sunday 30th today, I resealed the diff, filled in fresh oil coz the previous 20km fill was filled with metal. Checked total preload it was 10 in lb total, or right at 1Nm. Loaded the diff into the subframe. Took a test drive.

As I was inching out in 1st gear at very low speeds, I could hear some weird noises, but after about a 100meters, the noises went away.

I then proceed to drive to a dog park about 5km away. Top speed was 55kmh for a short burst, most of the speeds were 35 to 40kmh. Accel and decel, no abnormal noises. Parked the car for 1 hr.

The drive home I took it easy again, and one one stretch of road I went to 60kmh and topped 66kmh. There was a very faint sound that I could hear with the radio off. With the radio on I cant hear it. Remember I said on the 5th rebuild the whistle/whine was 1/5th of the 4th rebuild? Well for this test drive it was 1/5th of that 1/5th, so that is a tremendous improvement !

As I neared my home, I found another stretch of road and brought the car to 64kmh, again same results, There is a sound but I really need to pay attention to it to notice it.

I parked my car and felt relieved and pretty happy.

Lets see if it stays the same when I drive the car next saturday. So it does seem the noise was low pinion preload.

I think what was happening is with low preload the pinion must have moved around causing the rollers to slide partially on the races, causing the whistle, and also the pinion shifted position slightly changing the gear contact pattern.

Now with the high preload, it stiffened up the whole pinion -bearing and spacer assembly to the housing, causing all forces trying to push the pinion away , is unable to do so as the rollers, races and the housing are now working as one unit keeping the pinion where its supposed to be.

It certainly looks promising at this point.

Update. Considering how much trouble I have with my diff and with the front bearing shell being somewhat loose in the housing. I decide to buy this diff from a japan auction. Regardless if my current diff turns out ok over the long run.

yahoo.aleado.com

It costs 300USD total, and I have to wait 2 months. I plan on rebuilding it with used bearings that I already have, and buy New side seals, new center nut and a few LSD plates/clutches. This will be a low cost build for me, as I will be using the gears and pinion depth shim that comes with the diff. I also have 2 brand new crush sleeves , so I will use a crush sleeve on this build. Once done I will have back up diff that I can swap over. I will start another thread for this diff when I receive it.

yahoo.aleado.com

It costs 300USD total, and I have to wait 2 months. I plan on rebuilding it with used bearings that I already have, and buy New side seals, new center nut and a few LSD plates/clutches. This will be a low cost build for me, as I will be using the gears and pinion depth shim that comes with the diff. I also have 2 brand new crush sleeves , so I will use a crush sleeve on this build. Once done I will have back up diff that I can swap over. I will start another thread for this diff when I receive it.

[B154]GZ20,1G-GTEU, Soarer,SOARER,2,0GT twin turbo,1GGT, diff LSD,41:9 1^z: Real Yahoo auction salling

purchase: [B154]GZ20,1G-GTEU, Soarer,SOARER,2,0GT twin turbo,1GGT, diff LSD,41:9 1^z

Turns out the "LSD" i bought isn't a LSD but an open diff. The good thing is the backlash is very consistent, its towards the upper end of the range, at 0.19mm average. The ratio is also correct (as asked in my other thread, but I am stopping with that thread as it is not a LSD)

I took apart the diff last week, and found caked on oil inside. The bearings surprisingly look good, though covered in black film of caked on oil. I may just re use these bearings. I am now in the process of getting rid of the rust on the housing and the side gear flanges. I ordered new pinion nuts, and will be reusing my old low mileage seals. The seals on this diff look rusted and pretty bad. I should be able to put it all back together by the 28th Oct. The carrier shims are 2.97 ring gear side, 3mm opposite side, which gives total of 5.97mm. I plan to shift around the side shims to reduce backlash by a tiny amount. I also am gonna remove the inner pinion bearing, just to measure the pinion depth shim for my data.

Also , even if this rebuild nets me a silent diff, i will still reset my original diff. I plan to increase pinion preload on that diff a tad, and use back the original 1.94mm pinion depth shim, vs the 1.90mm shim I have in there now. There is still a noise over 60mkh, which is a faint whine, and over 70kmh it turns into a "card in bicycle spokes" sound. I suspect for OEM gear sets with exact stock ratio, I am not supposed to change the depth shim no matter what the gear pattern shows me.

I took apart the diff last week, and found caked on oil inside. The bearings surprisingly look good, though covered in black film of caked on oil. I may just re use these bearings. I am now in the process of getting rid of the rust on the housing and the side gear flanges. I ordered new pinion nuts, and will be reusing my old low mileage seals. The seals on this diff look rusted and pretty bad. I should be able to put it all back together by the 28th Oct. The carrier shims are 2.97 ring gear side, 3mm opposite side, which gives total of 5.97mm. I plan to shift around the side shims to reduce backlash by a tiny amount. I also am gonna remove the inner pinion bearing, just to measure the pinion depth shim for my data.

Also , even if this rebuild nets me a silent diff, i will still reset my original diff. I plan to increase pinion preload on that diff a tad, and use back the original 1.94mm pinion depth shim, vs the 1.90mm shim I have in there now. There is still a noise over 60mkh, which is a faint whine, and over 70kmh it turns into a "card in bicycle spokes" sound. I suspect for OEM gear sets with exact stock ratio, I am not supposed to change the depth shim no matter what the gear pattern shows me.

Last edited:

I would suggest to run it as is, that way you have a good starting point of how quit this diff is. Then if the pinion bearing preload is still ok, i would just leave it alone. Then only change to the LSD diff carrier with correct shims to get back to 0.19mm backlash and have a healthy preload on the carrier bearings.

Too late bruh, I had to take it apart and inspect everything. The bearings are coated with a black film of oil, so I cleaned them up thoroughly, I also want to measure the pinion depth shim, just to compare diff to diff. Overall, the bearings look really good for a 35 year old diff. In fact I noticed they have an extra marking on the pinion bearings, HI-CAP, vs the modern bearings I bought which have H.C only.I would suggest to run it as is, that way you have a good starting point of how quit this diff is. Then if the pinion bearing preload is still ok, i would just leave it alone. Then only change to the LSD diff carrier with correct shims to get back to 0.19mm backlash and have a healthy preload on the carrier bearings.

I also had to clean off the rust on the housing and there was plenty of rust. I used Naval Jelly rust dissolver, washed off, wire brush the loose rust, brake clean spray, then applied CRC rust converter, then primed and painted.

There is also a small amount of rust on edges of some pinion tooth so I am gonna wet sand that, and inspect the ring and pinion closely. The diff was sent dry for 2 months by sea shipment so it is expected.

So far the carrier bearings also look good, I plan to reuse them. The spider gears have some wear so I will reshim them.

Edit : I tried removing the inner pinion bearing , but the bearing splitter bent at the studs. So i bought new bolts, those bent too. So i give up for now, not gonna measure the pinion depth shim. I will be getting special studs made, that hopefully will withstand the forces.

Last edited:

I got my new pinion nuts from japan and tightened the nut to set preload. This is my first time working with a crush sleeve and it went smoothly. I mean i read on some forums how difficult it is to crush it, but the toyota ones were not that hard to crush. I just used a 4' long breaker bar, with two hands pulled down on it 1/16th of turn, and check the slop. I kept going for 20 minutes till there was no slop and got a preload of 3 inlb. I continued turning it another 5 times and rechecking after each time, after another 20 minutes, got it to 6 inllb rotating and 15 inlb breakaway. I am gonna leave it at that. The movement is smooth and no clicking noises.

The question now is, since this is a used gear set, should I reset the backlash to lower end of the spec at 0.13mm . Would this cause noise? Or I am better off reset backlash to 0.18 or 0.17mm, which is close to 0.19mm which was the setting before disassembly.

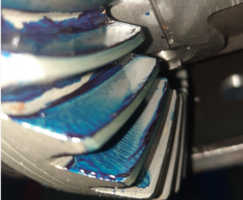

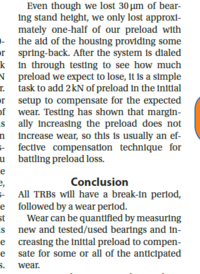

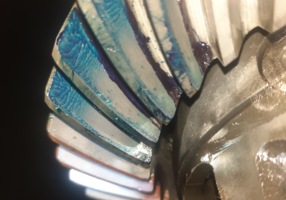

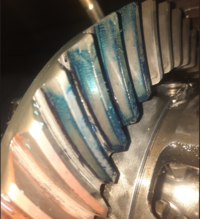

Edit : 24-Oct-2023. Placed carrier in with L shim 3mm, Right shim 2.97mm (flipped over). Backlash is reduced by 0.01mm, from 0.19mm average to 0.18mm average. Since this is a used gearset, i decide not to tighten the backlash anymore. Besides the measurement on dial indicator, the feel of the backlash feels tight, so I am gonna leave it at this. I ran a gear pattern, I know its not required on a used gearset especially with the same pinion depth that came with the diff, but I am just curious to see it. Drive side, extends a little from the center to the toe, not running off the toe, very similar to my original 1st diff.

Coast , not as long as the drive side, starts out at the center and go towards toe.

Plus, I turned my crank handle on the pinion, and it has no clicking or grinding noises. I guess I can finish the diff by tomorrow or thursday.

Just need to rust proof the diff cover bolts and reinstall side seals.

The question now is, since this is a used gear set, should I reset the backlash to lower end of the spec at 0.13mm . Would this cause noise? Or I am better off reset backlash to 0.18 or 0.17mm, which is close to 0.19mm which was the setting before disassembly.

Edit : 24-Oct-2023. Placed carrier in with L shim 3mm, Right shim 2.97mm (flipped over). Backlash is reduced by 0.01mm, from 0.19mm average to 0.18mm average. Since this is a used gearset, i decide not to tighten the backlash anymore. Besides the measurement on dial indicator, the feel of the backlash feels tight, so I am gonna leave it at this. I ran a gear pattern, I know its not required on a used gearset especially with the same pinion depth that came with the diff, but I am just curious to see it. Drive side, extends a little from the center to the toe, not running off the toe, very similar to my original 1st diff.

Coast , not as long as the drive side, starts out at the center and go towards toe.

Plus, I turned my crank handle on the pinion, and it has no clicking or grinding noises. I guess I can finish the diff by tomorrow or thursday.

Just need to rust proof the diff cover bolts and reinstall side seals.

Last edited:

Guys, I am almost done, I knocked in the side gear flanges, but oddly I find that the ring gear side flange has very little in out slop, but the opposite side has about 2 to 3mm of in out slop . Is this normal ? If i recall my other open diff is the same. Any reason why toyota made it this way ?

I was just able to test the car after swapping in the diff last week.

When the oil is cold, there is hardly any noise, approach 50kmh, I hear nothing. At 60kmh I hear nothing, then at 62 I start hearing something, though it is much fainter than my original diff. As the oil heats up, the sound at 60kmh gets louder. However at temp, it is still not as loud as my original diff. I would say half the loudness. Also when hot at decel above 60kmh I do hear some whine, go below that its silent. I went up to 85kmh and while there is a hum, there are no card in bicycle wheel sound. Overall there is an improvement over my old diff. The diff feels solid and smooth. For this auction diff, there is nothing much I can do except change the bearings to a complete set of low mileage bearings which I already have. Supposedly, this auction diff has 235000 km on it. For a gear and bearing set that is 35 years old , I guess it's ok. I cannot mess with pinion depth and backlash. Maybe this sound is the tiny backlash reduction , or the 35 year old bearings. The carrier bearings do have lots of wear lines in the shells, but they are smooth and no changes in elevation on the surface. The rollers are also not pitted, that's why I reused them. If after changing the bearings and still have sound, then it must be gear noise, nothing else I can do.

So now I have my original diff at my workplace, I will be doing a few things, increase pinion preload, increase pinion depth (with original shim 1.94mm), reduce backlash a little, and increase carrier preload. I am still waiting for my special studs I ordered so I can use my pinion bearing puller.

Maybe in 2 weeks time I will swap the diffs again, test my original diff, change bearings and crush sleeve on the auction diff....

Hopefully the next swap will be silent...

When the oil is cold, there is hardly any noise, approach 50kmh, I hear nothing. At 60kmh I hear nothing, then at 62 I start hearing something, though it is much fainter than my original diff. As the oil heats up, the sound at 60kmh gets louder. However at temp, it is still not as loud as my original diff. I would say half the loudness. Also when hot at decel above 60kmh I do hear some whine, go below that its silent. I went up to 85kmh and while there is a hum, there are no card in bicycle wheel sound. Overall there is an improvement over my old diff. The diff feels solid and smooth. For this auction diff, there is nothing much I can do except change the bearings to a complete set of low mileage bearings which I already have. Supposedly, this auction diff has 235000 km on it. For a gear and bearing set that is 35 years old , I guess it's ok. I cannot mess with pinion depth and backlash. Maybe this sound is the tiny backlash reduction , or the 35 year old bearings. The carrier bearings do have lots of wear lines in the shells, but they are smooth and no changes in elevation on the surface. The rollers are also not pitted, that's why I reused them. If after changing the bearings and still have sound, then it must be gear noise, nothing else I can do.

So now I have my original diff at my workplace, I will be doing a few things, increase pinion preload, increase pinion depth (with original shim 1.94mm), reduce backlash a little, and increase carrier preload. I am still waiting for my special studs I ordered so I can use my pinion bearing puller.

Maybe in 2 weeks time I will swap the diffs again, test my original diff, change bearings and crush sleeve on the auction diff....

Hopefully the next swap will be silent...