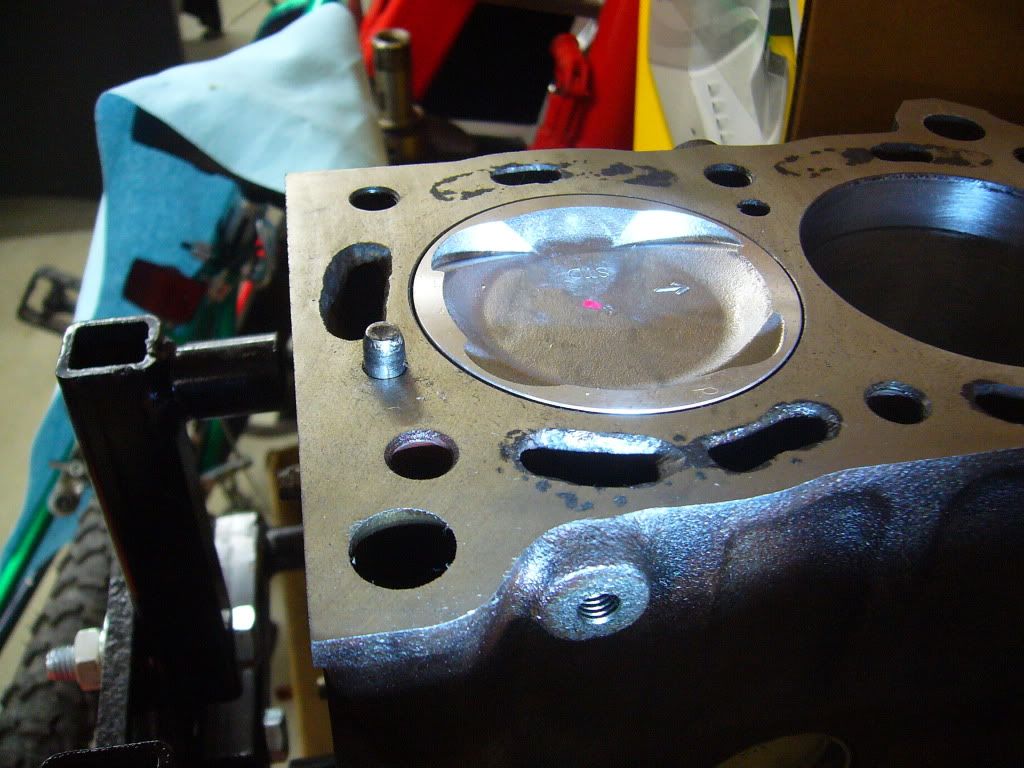

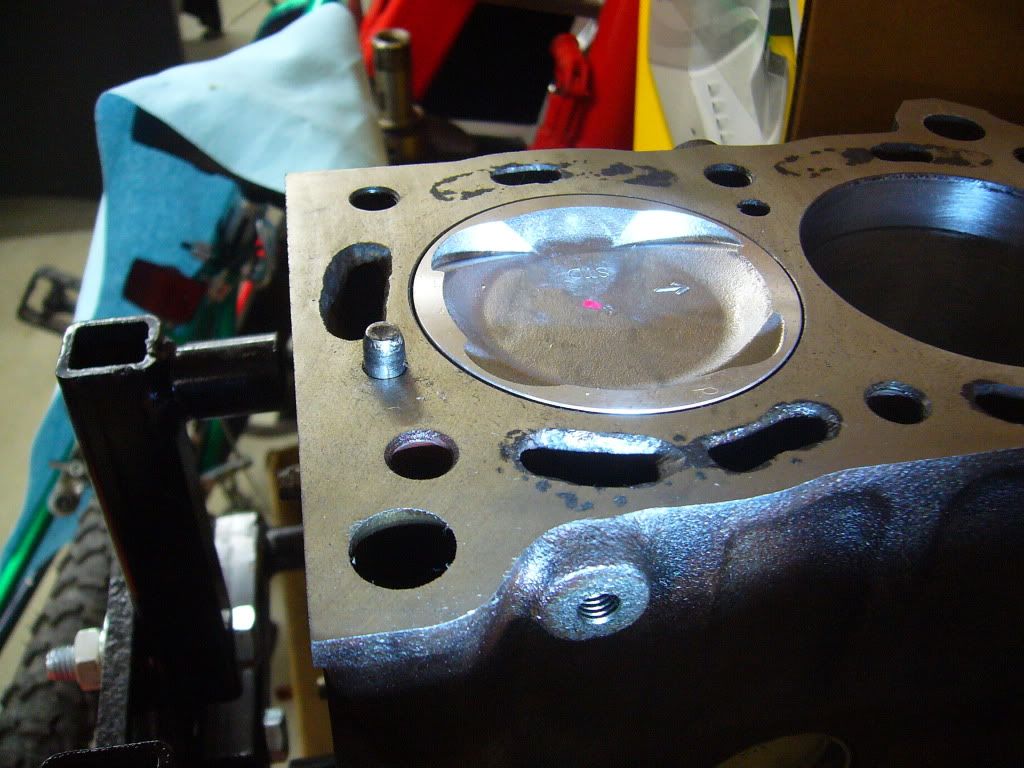

Second UPDATE : Block look like junk...IT look like the pit are way to depth and the gasket will never be able to seal. I can't understand why they dont tell me that this block is junk. + I took some pics of the cylinder wall, there is rust in it. I can't feel it but we easily see eat. LEt me know if its really junk and i will ask for a refund on the block labours ( decking + man hour)

The head : i put my vernier on it : 115.75mm, so it look like a will be able to get a better finish of this one.

DOes the bearing are reusable?? They are set with the crank ( which is good) only or with the block and crank?? ( want to know if i ask for a refund this too) thanks

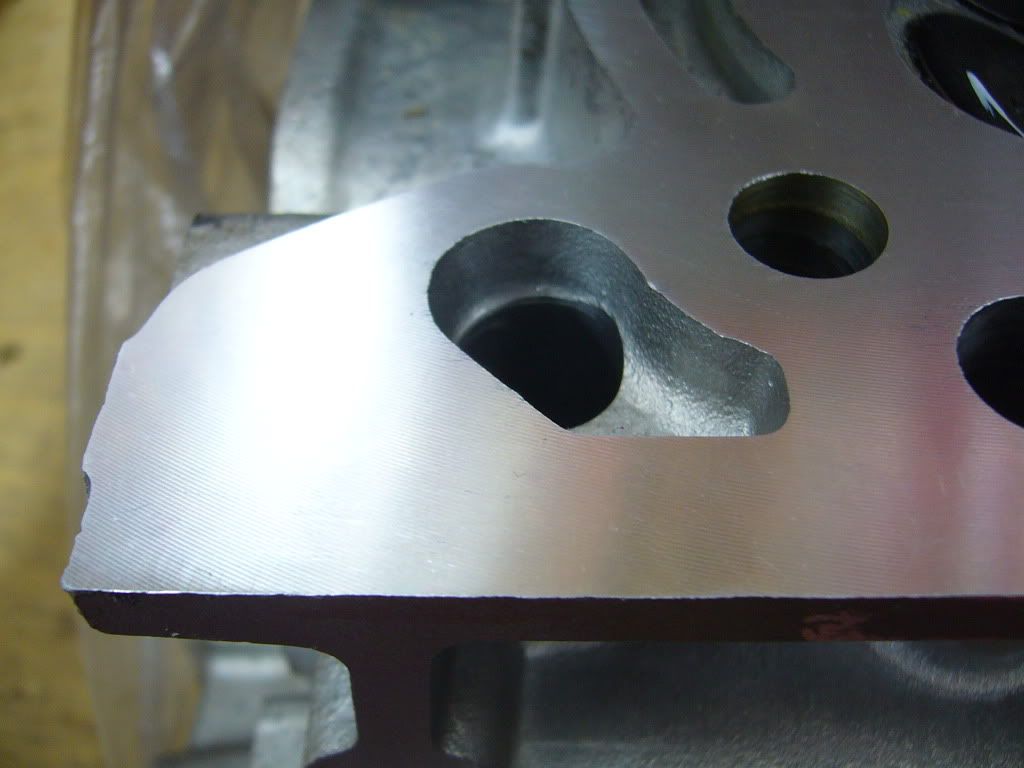

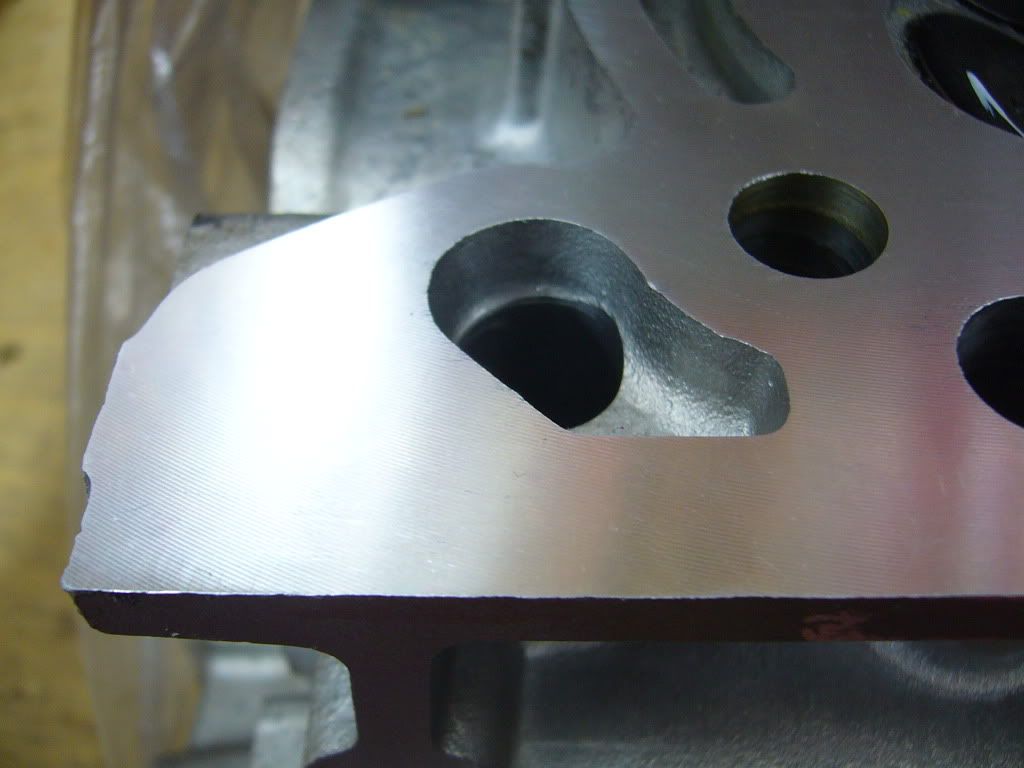

UPDATE : HEAD SURFACE PICS. I supposed that this is not enough for a MHG. Let me know.

HI, i just received my block coming from the machine shop. I ask the guy to make the block as smooth as possible and they tell me then can get it really smooth. Decided to give them a try. Now, look at my block surface, what do you think about it? To me, it look like crap and i will not be able to use my Cometic MHG (1.8mm thick). We can see rough surface near the #6 cylinder.

Is it possible to get the block surface machined in an other machine shop to get better surface without removing the piston?? I have new piston inside + new bearing and etc and dont want to get it out a second time. I was thinking about filling the cylinder with grease.

What to do?? THANks to help me.

The head : i put my vernier on it : 115.75mm, so it look like a will be able to get a better finish of this one.

DOes the bearing are reusable?? They are set with the crank ( which is good) only or with the block and crank?? ( want to know if i ask for a refund this too) thanks

UPDATE : HEAD SURFACE PICS. I supposed that this is not enough for a MHG. Let me know.

HI, i just received my block coming from the machine shop. I ask the guy to make the block as smooth as possible and they tell me then can get it really smooth. Decided to give them a try. Now, look at my block surface, what do you think about it? To me, it look like crap and i will not be able to use my Cometic MHG (1.8mm thick). We can see rough surface near the #6 cylinder.

Is it possible to get the block surface machined in an other machine shop to get better surface without removing the piston?? I have new piston inside + new bearing and etc and dont want to get it out a second time. I was thinking about filling the cylinder with grease.

What to do?? THANks to help me.

Last edited: