Ok I started this thread on *another forum* and wanted to see if SM's Finest had any input.

Ok, So I am currently building a 7MGTE that I would like to use in a 4x4 truck for off road fun.

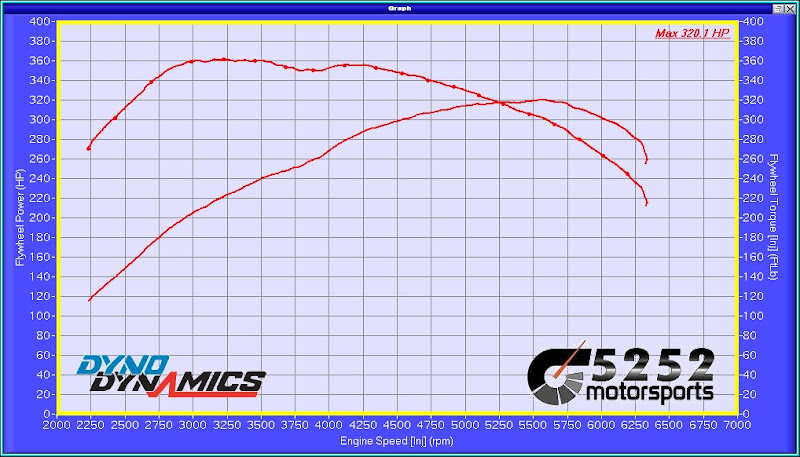

So instead of going for big numbers High RPM I will be shooting for low end torque.

I know the 7M is perfect for this (without going UZ) becuase of its under square bore to stroke ratio.

So Far I have:

8.9:1 JE pistons (Not 100% on the CR, I will check when I get home)

Mildly PNP Head

Stock valves

Chevy Big Block valve springs

1.4 Titan Motorsports MHG

ARP everything

New oil pump

Adjustable cam gears

Will be ordering MAPECU2

I was looking at BC stage 2 cam shafts, is this a wise choice to optimize low end torque?

Would I be better off going with a twin turbo setup with the OBX TT manifold?

Or would a single get me what I need?

GOAL: 240+ ft/lb before 3000rpm

Is there anything else I can do to squeeze more torque out of this motor?

There were many useful responses

My standing questions are:

Cam Choice?

Will running such a small turbo at rpms above 4000 be bad for it? Will I have to bring my redline down?

Any other input would be greatly valued!

Ok, So I am currently building a 7MGTE that I would like to use in a 4x4 truck for off road fun.

So instead of going for big numbers High RPM I will be shooting for low end torque.

I know the 7M is perfect for this (without going UZ) becuase of its under square bore to stroke ratio.

So Far I have:

8.9:1 JE pistons (Not 100% on the CR, I will check when I get home)

Mildly PNP Head

Stock valves

Chevy Big Block valve springs

1.4 Titan Motorsports MHG

ARP everything

New oil pump

Adjustable cam gears

Will be ordering MAPECU2

I was looking at BC stage 2 cam shafts, is this a wise choice to optimize low end torque?

Would I be better off going with a twin turbo setup with the OBX TT manifold?

Or would a single get me what I need?

GOAL: 240+ ft/lb before 3000rpm

Is there anything else I can do to squeeze more torque out of this motor?

There were many useful responses

Wreckless;8795321 said:Best bet for maximum torque is to make everything geared towards making low RPM power. To that end, stock cams will probably be the best, especially with those adjustable cam gears. The OBX TT manifold is set up for Greddy 3 bolt inlet flanges just like the original Greddy piece, and sourcing turbos to fit that at all, let alone turbos that would suit your power goals, is basically a 'not gonna happen' sort of thing.

What you'll want is a small single turbo like an internally gated GT3071R or something similar. Have a fabricator make you an adapter to go from a CT26 flange on the stock cast manifold to a T25 or T3 flange directly. Running an internal gate means that boost will come on more gradually, which will make it easier for you to modulate the throttle in 4wd climby situations.

You might even consider something even smaller like a GT2860RS. The sooner you're making full boost, the sooner you're into your big torque curve. If you're dead set on full boost before 3k I'd go for the GT2860RS, as while that turbo will be maxed out around 325whp, it's responsive as hell on 1.6-2.0L 4 cylinders, which means it'd be even more responsive on a 3.0L. It'll fall off and die in higher RPM compared to more traditional options seen on 7M-GTE's such as T61's, etc. But it'll be very strong below 5k and that's where you'll be making torque.

In short, you will have to go to a smaller frame turbo on a T25 or T3 footprint from a cast manifold to best achieve what you want. CT based turbos will NOT get you there, and T4 based turbos aren't likely to either, even if equipped with a QSV.

Because you'll be running them on a 3.0L, consider the larger hotside available for whatever turbo you choose, as larger engines need the reduced restriction and being a 3.0L it'll spool those little bitty turbos like crazy even on their 'big' turbine housings.

Doitzel_Kaiser;8796429 said:

So I have done a little research and using the GT3071R as my Turbo and aiming for 350 HP which would be approx. 35lb/min, the compressor map tells me my Pressure Ratio should be around 2.8.

So if I bring this over to the Turbine map, I get a little confused but I think the .64AR is my best bet.

Right?

Wreckless;8796478 said:Yes, a cast manifold will almost always beat a tubular manifold to boost threshold. Where tubular manifolds shine is in higher RPM stuff and overall backpressure reduction.

The turbine flow map is how much gas can flow through the turbine at a given pressure ratio. Your backpressure will always be higher than your intake pressure, and so running the .64 will bottleneck your overall power band and elevate EGT's and generally limit how much power you can make in a big way. Remember we're not talking about a .64 turbine housing on a P-trim T66 here, it's a little GT3071.

The .86 will spool a little slower, yes, but you'll get a lot more out of that GT3071R as a result, and most of the gains in response will be seen from running such a small turbo on a 3.0L to begin with, particular on a cast manifold.

That said, I don't have any data or any experience or results from anyone that's run a GT3071R on a 7M-GTE. You should also consider the GT3076 and GT3082, although those would both require an external wastegate.

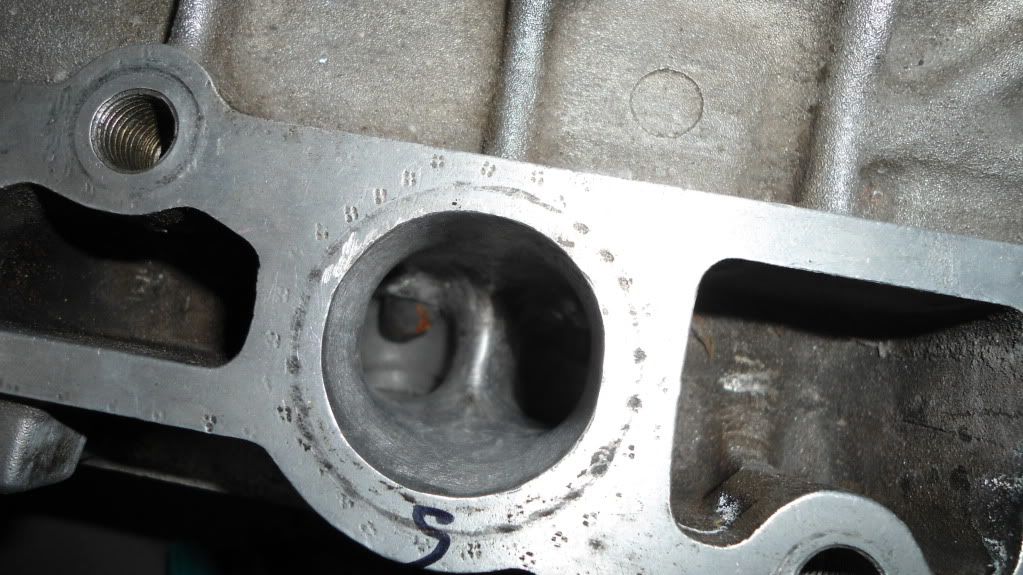

Doitzel_Kaiser;8797116 said:So about the cam shafts, My stock cams were out of spec (journals measured too low) Is it worth tracking down some GE cams or just replace GTE cams?

My standing questions are:

Cam Choice?

Will running such a small turbo at rpms above 4000 be bad for it? Will I have to bring my redline down?

Any other input would be greatly valued!

Last edited: