There's a few thin spots in there close to water Seth, I posted a bunch of pics awhile back of one I sectioned before porting a new casting.

7M meet Technology!

- Thread starter sethron71

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hey IJ,

Yea we were talking about this the other day. I thought about doing this to a head and then cutting it up into pieces to allow me to see danger areas. As I mentioned right now the goal is to just remove enough material to remove the casting inconsistencies which is about .050". As well when I get into the porting, I am not trying to hog out it just make the ports consistent and smooth!

Rich, thank you for the information! Cool part is if I real got extreme I could send a custom piston maker my drawing and they could make and identical piston to match! Still trying different tooling to get the bests surface surface finish!

Thanks again for the input, keep it coming. Very receptive to all ideas!

Seth

Yea we were talking about this the other day. I thought about doing this to a head and then cutting it up into pieces to allow me to see danger areas. As I mentioned right now the goal is to just remove enough material to remove the casting inconsistencies which is about .050". As well when I get into the porting, I am not trying to hog out it just make the ports consistent and smooth!

Rich, thank you for the information! Cool part is if I real got extreme I could send a custom piston maker my drawing and they could make and identical piston to match! Still trying different tooling to get the bests surface surface finish!

Thanks again for the input, keep it coming. Very receptive to all ideas!

Seth

hvyman;1681725 said:Didnt the group a cars have just a round combustion chamber?

The full race ones sure did.

That turned them into a head that had chambers very close to what the 2J, and RB heads have.

The stock Group-A heads just had the 2 protrusions taken out, as they restrict flow.

I think there is a picture or 2 of the Gr.A head chambers here somewhere.

Seth, it would be nise if you can remove the old corners next to the valves, and get those protusions out.

from the author of that page:

picture of the group A racing head. All squish pads gone, as far as I know they don't offer any advantage at high load/rpm, but very good thing for street engine because they promote turbulence in combustion chamber.

Enraged;1681904 said:from the author of that page:

Another meaningless rant by someone who didn't know what they were talking about.

Squish areas can be designed into the piston domes.

The improvement in flow is quite large, kind of why all modern 4-valve heads are shaped along those lines.

I repeat, like the 2J, RB, SR, B18, etc., etc..

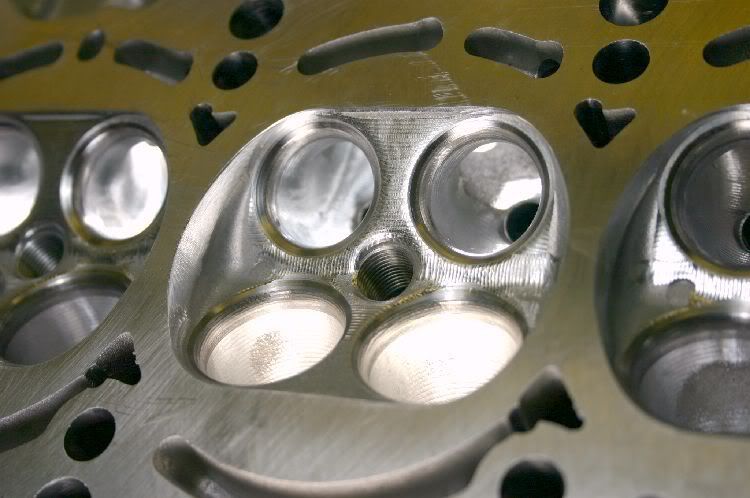

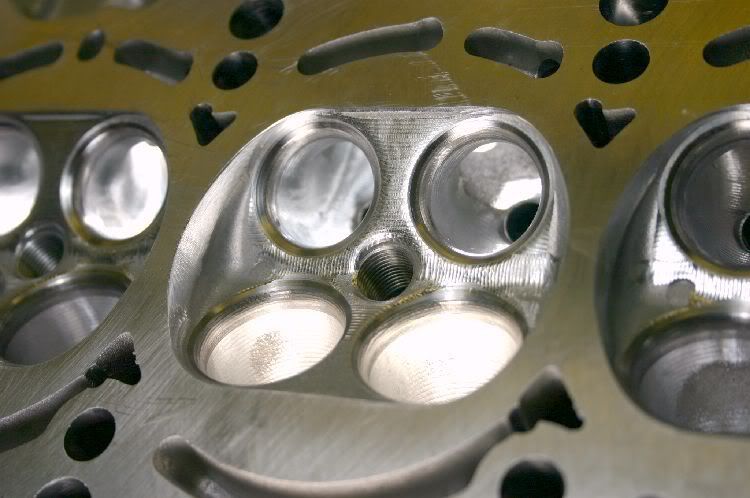

2J CNC Head:

Matching pistons:

Wonder if there are flat top pistons in production currently for the 7M? Rich you have probably come across them or had them made for that matter!

Seth

Matching pistons:

Wonder if there are flat top pistons in production currently for the 7M? Rich you have probably come across them or had them made for that matter!

Seth

I just received a set of JE flat tops.

Called them up, and had them make their standard piston with no dish.

Kept the same valve pocket depth.

Nice thing is, even though I didn't request it, they took more material off the underside to keep the weight down.

Thought I would have to do that myself, but they evidentally think a little bit ahead.

My cost was about $975 to my door.

Called them up, and had them make their standard piston with no dish.

Kept the same valve pocket depth.

Nice thing is, even though I didn't request it, they took more material off the underside to keep the weight down.

Thought I would have to do that myself, but they evidentally think a little bit ahead.

My cost was about $975 to my door.

very nice work on the cnc chambers, i like it!

interesting that the group A head has no squish areas, is all the swirl generated in the piston shape? i will be using flat top pistons in my 9000rpm NA build, so from what i know i will need to keep the squish pads in the head for some swirl?

also does anybody know what the max OS on the intake valves is if using OS seats? i would like to squeeze 34mm in there if possible....

a couple more sectional views from a head a cut up a little while ago:

http://www.toymods.org.au/forums/showthread.php?63223-7M-Head-Cross-Section

interesting that the group A head has no squish areas, is all the swirl generated in the piston shape? i will be using flat top pistons in my 9000rpm NA build, so from what i know i will need to keep the squish pads in the head for some swirl?

also does anybody know what the max OS on the intake valves is if using OS seats? i would like to squeeze 34mm in there if possible....

a couple more sectional views from a head a cut up a little while ago:

http://www.toymods.org.au/forums/showthread.php?63223-7M-Head-Cross-Section

Hey Rich or IJ,

Would be worth it to O-Ring the head? Setup to machine that would be nothing once the head is already in the machine!

Seth

Would be worth it to O-Ring the head? Setup to machine that would be nothing once the head is already in the machine!

Seth

Bore spacing makes O-ringing a 7M "difficult" at best, I don't see any advantage over a MHG correctly installed Seth and the downside is if you ring the head and there are any uneven loadings during use the ring will sink and unload....

(I O-Ringed my 4V Toyota V8 but cut the tops of the Iron liners and not the heads.)

(I O-Ringed my 4V Toyota V8 but cut the tops of the Iron liners and not the heads.)

Yea I was reading that people say cutting the block is best. Was just a thought though because once the head is chucked up the setup is almost nothing to do something like that as you would know! but thanks for the help.

Seth

Seth

Seth, I second what IJ said. No need to o-ring any part of the 7m. Gary is running 1400 RWHP on the Malta 7m with nothing more than a hks 2mm stopper and off the shelf ARP studs.

Andrew - for a 34mm valve, you would need some serious cams to make use of them. With a big lift, valves of that size you may find may not clear each other at certain cam timing events. That is why I have raised the valve seat in the past in order to provide a greater distance between the valves.

Andrew - for a 34mm valve, you would need some serious cams to make use of them. With a big lift, valves of that size you may find may not clear each other at certain cam timing events. That is why I have raised the valve seat in the past in order to provide a greater distance between the valves.

Thought i'd throw this in for good measure, as you all know what the Group A Head setup looks like, and the stocker - so here's the "half-way house" version by TRD:

From the looks of that(TRD Design) they did not take any depth at all but as you can still see the casting mark in the bottom(that circle in the bottom of the bow.) That design is very close to the 2J design just with that tip between the two intake valves left behind. Obviously there is a large amount of material removed but I am not sure how much that is going to affect actual CC's and CR.... I guess the only way is to try all the different designs, CC them and then figure out which approach is best.

Seth

Seth

just remember that dimple is were the ground tag is suppost to point for best results so i have been told many time by some pretty smart people

I see a lot of comments about improving swirl...but swirl is not really wanted in this engine.

When it comes to spark ignited engines you want tumble due to a flamefront growing from the sparkplug and out to towards the cylinder walls. More swirl in an SI engine will give richer residual gases which in turn will result in high HC.

With an diesel engine on the other hand, you want as much swirl as possible. Don't think I need to expand on this since this is far from subject.

Humps between intake and exhaust valves are also there to help avoiding internal EGR due to overlap between intake and exhaust cams.

EDIT: Seth, nice CNC work you are doing to the head. Good luck and I will follow your progress.

When it comes to spark ignited engines you want tumble due to a flamefront growing from the sparkplug and out to towards the cylinder walls. More swirl in an SI engine will give richer residual gases which in turn will result in high HC.

With an diesel engine on the other hand, you want as much swirl as possible. Don't think I need to expand on this since this is far from subject.

Humps between intake and exhaust valves are also there to help avoiding internal EGR due to overlap between intake and exhaust cams.

EDIT: Seth, nice CNC work you are doing to the head. Good luck and I will follow your progress.