Kai, put some sort of shield around the opening of the AFM, or it will not idle properly. If you still have the back piece of the stock air box that would work.

1990 Toyota Supra Turbo Buildup - Satans Little Helper...

- Thread starter Kai

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Will try - although i'll have to relocate the PS reservoir again. Figured out why the starter wont kick over as well....its missing a wire

Kai;1734227 said:Figured out why the starter wont kick over as well....its missing a wire

But the wiring is perfect! We were told! :wuteva:

So today, after getting back from the store, i decided that enough was enough, and it was going to run...TODAY. No if's, no buts, no arsing around, just jacked it up, plugged in the starter motor (after much huffing and puffing with the jack), and it kicked over. So, EFI fuse was removed, some cheap 10w40 flushing oil was put in (it's getting drained out tomorrow, and fresh stuff is going in, along with a new filter), fresh, luminous green coolant and distilled water. Cranked it for 30 seconds+ to build oil pressure, and voila, pressure! GOOD pressure, too!

EFI fuse was plugged back in and....it started. Ish. After initially getting concerned there may be a wider issue, it turns out that the CPS was merely installed a few teeth out. Thanks to shaeff's excellent guide here: http://www.supramania.com/forums/showthread.php?38775-How-To-basic-timing-instructions-CPS-alignment, i was able to plug the CPS in the right way, set perfectly to 0* TDC. Upon putting everything back together....ladies and gentlemen - IT LIVES AGAIN!

[video=youtube;wMvOj0KqA2k]http://www.youtube.com/watch?v=wMvOj0KqA2k[/video]

I am SUPREMELY happy! Of course, i still need to sort out the timing properly, with a timing light, and tighten the turbo elbow. but for today, i think that's enough - i'll do that all tomorrow when i do the ps fluid reservoir fill, oil and filter change, and i have to get some more distilled water to top up the rad, i don't think 6 1/2 litres is enough!

Just need to sort out the valve clearances, and an air filter adapter so i can chuck on a cone filter

EFI fuse was plugged back in and....it started. Ish. After initially getting concerned there may be a wider issue, it turns out that the CPS was merely installed a few teeth out. Thanks to shaeff's excellent guide here: http://www.supramania.com/forums/showthread.php?38775-How-To-basic-timing-instructions-CPS-alignment, i was able to plug the CPS in the right way, set perfectly to 0* TDC. Upon putting everything back together....ladies and gentlemen - IT LIVES AGAIN!

[video=youtube;wMvOj0KqA2k]http://www.youtube.com/watch?v=wMvOj0KqA2k[/video]

I am SUPREMELY happy! Of course, i still need to sort out the timing properly, with a timing light, and tighten the turbo elbow. but for today, i think that's enough - i'll do that all tomorrow when i do the ps fluid reservoir fill, oil and filter change, and i have to get some more distilled water to top up the rad, i don't think 6 1/2 litres is enough!

Just need to sort out the valve clearances, and an air filter adapter so i can chuck on a cone filter

You're not going to use Toyota ( red ) coolant? I read up on a few things saying Toyota uses their additives to help the water pump not corrode and die fast. Anyhow I am glad to hear this is going well!

It's a new water pump for one, and secondly, although i have two 5 litre bottles of it in the UK in a Friends Garage, it's stupid money here - upwards of $20 a bottle. Same as oil & transmission fluid :/

It'll have to wait til August i'm afraid - there's little in the way of extra funds - surely generic anti-freeze can't be THAT bad?

Kai;1736238 said:It'll have to wait til August i'm afraid - there's little in the way of extra funds - surely generic anti-freeze can't be THAT bad?

No, it's not. Just be sure to completely rinse the system. Toyota Red reacts badly with some other coolants.

I'll do what i usually do - unplug the rad, shove a hose in the top and leave it til the stuff coming out the bottom is clear.

Supracentral;1736234 said:It's expensive here too Kai, I use it.

Yeah is it here. I pay $18.00 I believe, at one dealership I was charged more. Toyota will sell one US gallon not premixed. So you get 2 Gallons out of it. Honda on the other hand only sells you their coolant in a 50/50 mix which is total BS.

Small update - got the thing up to temperature again, and set the static timing to 10' BTDC with my timing light. Unfortunately, the idle is jumping around from 750 to 950rpm, which is a little annoying, although I *think* most of it is due to there being a missing vacuum line from the power steering pump to the pipe running from the AFM to the turbo. I might have the original line around here somewhere, else I may have to order another one...sigh :/

The coolant temperature sensor is giving me cause for concern too, as it doesn't seem to want to show anything. Could just be a bad connection though, i'll try it again tomorrow. I want a dry day again, its soaking wet under the car, and I want to swap out the run-up oil for some 10w40 break in oil.

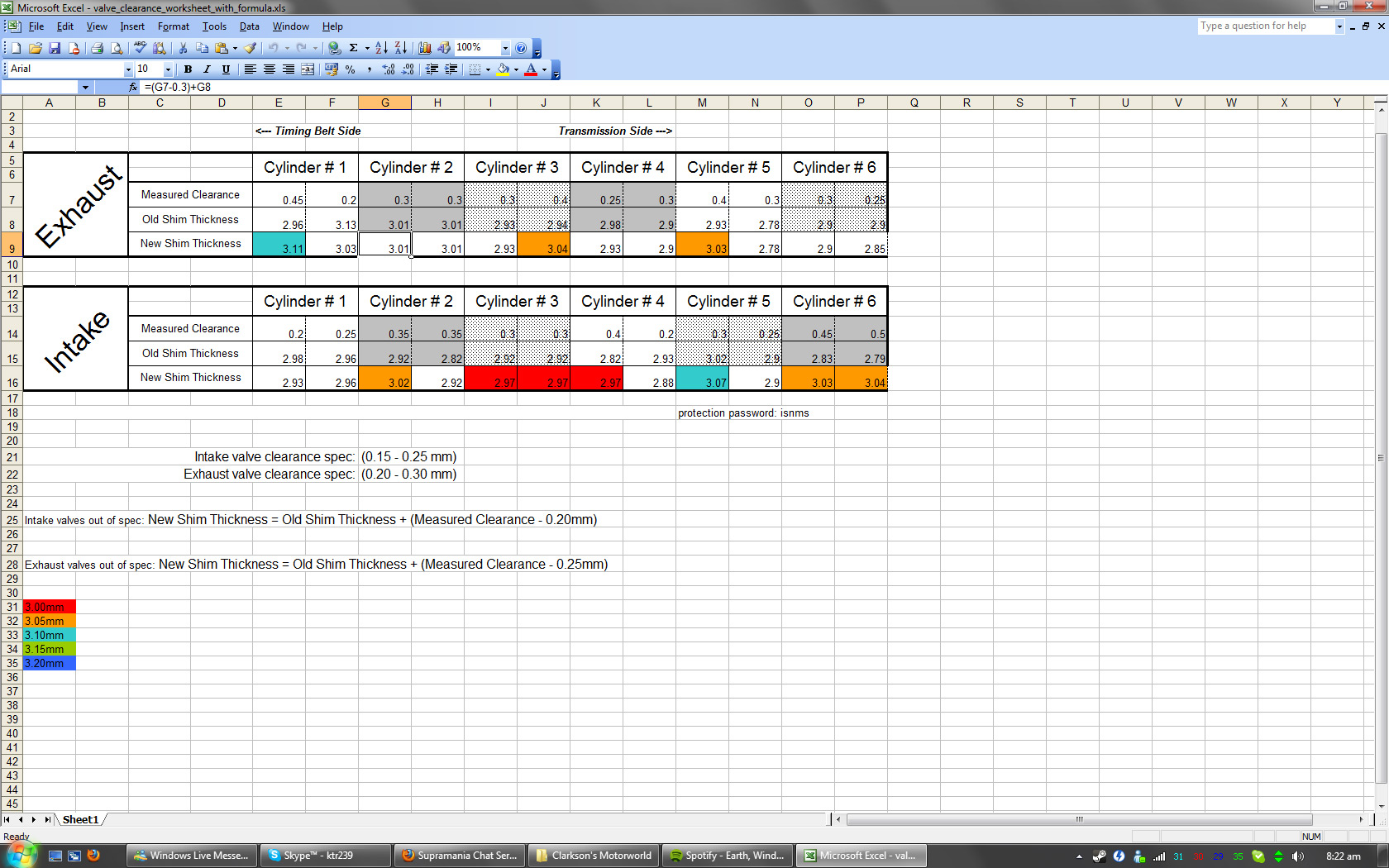

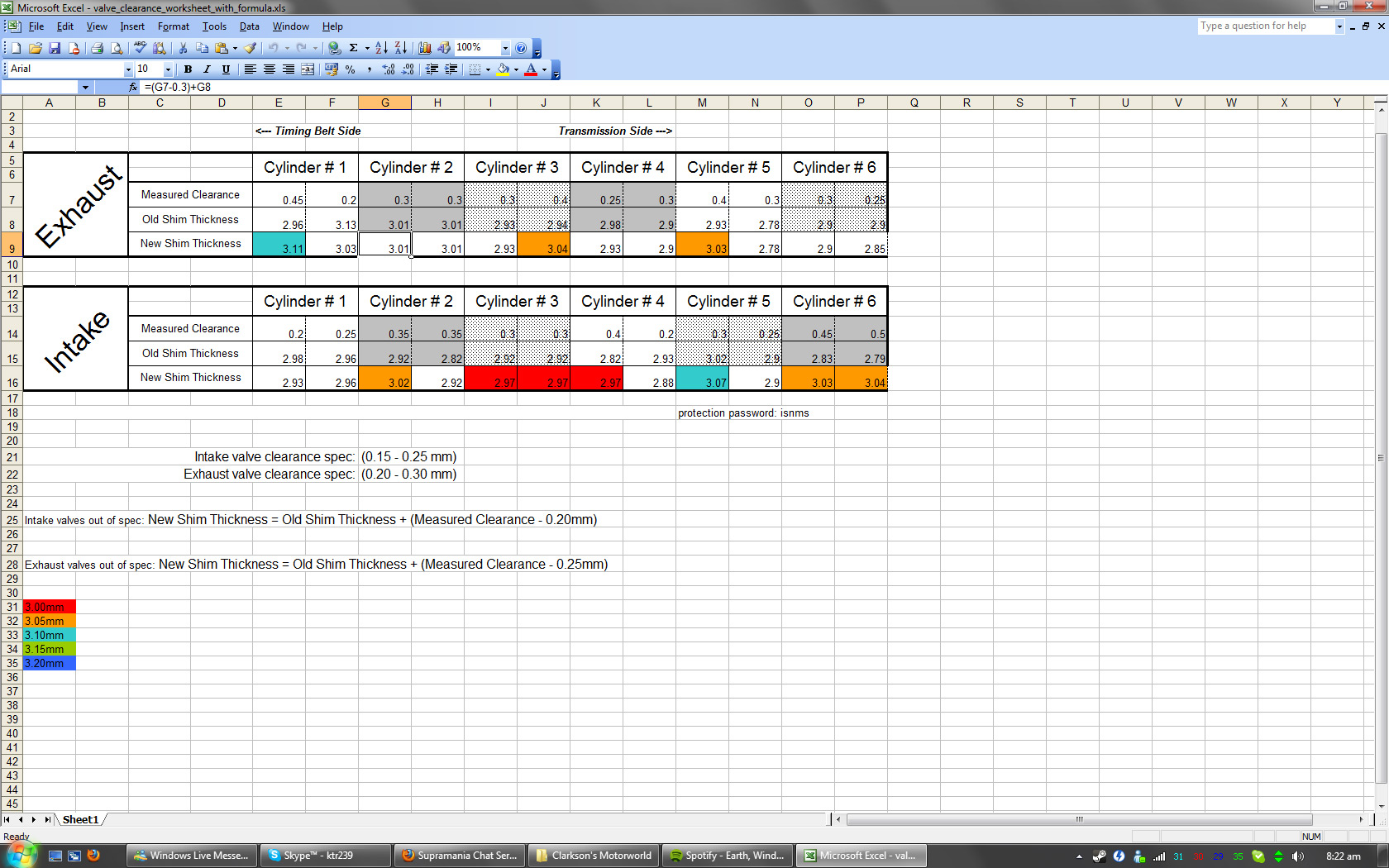

Thanks also to my lovely fiancee, who told me she's going to order me 4 of the 9 valve shims I need - toyota charges £10 a pop for them, but as she lives on guernsey, where there's no VAT, they're £7.50 each instead

The top end really *IS* clattery - here, have a look at the valve clearances I had to put it together with:

Cylinder #6 on the intake side is the worst!

The coolant temperature sensor is giving me cause for concern too, as it doesn't seem to want to show anything. Could just be a bad connection though, i'll try it again tomorrow. I want a dry day again, its soaking wet under the car, and I want to swap out the run-up oil for some 10w40 break in oil.

Thanks also to my lovely fiancee, who told me she's going to order me 4 of the 9 valve shims I need - toyota charges £10 a pop for them, but as she lives on guernsey, where there's no VAT, they're £7.50 each instead

The top end really *IS* clattery - here, have a look at the valve clearances I had to put it together with:

Cylinder #6 on the intake side is the worst!

Ladies and Gentlemen....the BITCH IS BACK!

Got the old power steering fluid reservoir re-installed as the there was no way of mounting the N/A one for the moment. The coolant temperature gauge (arguably the most important one) doesn't work, either. Which is annoying. Means i have to take the dashboard out all over again >_<

I have an exhaust leak somewhere as well, which means i only see about 6psi of boost, but it goes like stink. Brakes needed some 'creative cleaning' (ie, taking it down the road at 100mph+ and slamming on the anchors!), but i'll need new pads at the very least - these ones are almost dead.

Got the old power steering fluid reservoir re-installed as the there was no way of mounting the N/A one for the moment. The coolant temperature gauge (arguably the most important one) doesn't work, either. Which is annoying. Means i have to take the dashboard out all over again >_<

I have an exhaust leak somewhere as well, which means i only see about 6psi of boost, but it goes like stink. Brakes needed some 'creative cleaning' (ie, taking it down the road at 100mph+ and slamming on the anchors!), but i'll need new pads at the very least - these ones are almost dead.

You probably already did this, but make sure your temp sensor plug at the water elbow is on securely before you rip out the cluster.

It'd be nice it that's all you needed to do.

It'd be nice it that's all you needed to do.

It's been over two years since i updated this thread, and i still have the car, although since my move to the UK, it's been kinda languishing in France. It still starts & drives, but still needs the valve clearances to be sorted and for it to be fitted with an AFPR. It'll take me a few months until i can get it trailered back to the UK to properly work on it, so in the meantime, i bought a spare 7M-GTE from my friend stuey (supradupra on here, the guy with the fantastic JZA70 GT Limited). Got basically everything i need, barring a CT26 - even comes with the often missing turbo stays!

Here it is, sitting in a garage, on an rubber backed carpet (don't want it rotting away on the damp concrete!):

Now that my financial situation is vastly improved, and more stable than before, i've made the decision to do a proper engine build, from the block up, rather than just a top end rebuild - which i'm still not entirely happy with. It'll take a long time - at least two years, to get all the parts together, but i'm taking a leaf out of JDMMA70's book - don't rush the build, don't skimp on parts or machine work, do it slowly as i can afford it.

The chassis will need work doing to it as well, although now i'm back in the UK, getting friends round to give me a hand will be much, much easier. Even the fact i have a CHOICE of machine shops within 20 miles of me is a damned luxury, compared to rural france. Welding will be required on the front drivers side strut tower, something i hadn't noticed before - and the rear drivers side outer arch section will need some work doing to it. Not happy about the emergency patch welds on the inner arches either, will have to sort those out as well - just hand me a MIG welder and i'll be off for a week :

:

So - how does the engine stand at the moment? Well, in the process of stripping it down and determining it's condition. Head has been skimmed by 0.019" (0.48mm) in the past, and has a good finish on it. Was used with an HKS Bead type headgasket - something i gather is like finding rocking horse poo now. The only slight concern, is the fact a lot of the exhaust studs were replaced with helicoils (engine BHG'ed in the distant past), and another stud chewed up the head when i was stripping it down. I do have another two heads on potential standby, thanks to JDMMA70's texas contacts. Gasket has very little use on it as well, and it's in good condition, so i'll be more than happy to re-use it once i've stripped off all the viton. Took the head through the local jetwash, too, and it came up a treat - barely any varnish, it's been well maintained, this engine.

The rotating assembly still spins freely, despite not having been run for a few years, the bores are mostly clear of rust, although theres a little bit of surface rust and pitting on cylinder #2, nothing too bad.

So, what's the plan, overall? Well - i like the phrase 'go big, or go home'. But it's not going to be a mega-hp build, but aiming for a comfortable 450rwhp, which is about right, for the chassis - i don't want the back end stepping out on me, and in almost constantly damp/drizzly england, grip is not something that is abundant for 6 months of the year. I'm being absolutely meticulous with this -everything that comes off is labelled, bagged and tagged.

Machine Work:-

Cylinder Head Checked for Surface Hardness - if it's annealed, keep the shims, bin it. ** TOP PRIORITY **

If it checks out okay, then;

Drill out & Helicoil Exhaust Stud #6 with 7/16 kit from DM.

Thoroughly clean, remove all traces of viton from head surface with Acetone

Check & Machine valve seats per TSRM spec

Polish & de-burr camshaft lobes, check for minimum height.

Port & polish the head (do that myself with a dremel, die grinder etc)

Port & polish the inlet & exhaust manifolds, give the exhaust manifold a thermal coating (any recommendations?)

Get block magnafluxed to check for fracturing

Clean Block thoroughly, remove rotating assy. & have bores checked for ovalling & crosshatch, if possible, avoid boring, just re-hone.

Have the block surfaced to remove no more than 0.15mm material, preferably to an RA of 30 or better.

Get crankshaft checked for oval journals, polish regardless. Plastigage clearances with stock rods & bearings, replace with new.

Balance whole rotating assembly.

Components:-

Full Toyota OEM Engine Gasket Set

Plastigauge - lots of it!

Permatex Assembly Lube

ARP Head Stud Kit

ARP Main Stud Kit

ARP Rod Stud Kit

ACL Duraglide bearings & thrust washers

Eagle Rods

CP Pistons

Ferrea 6000 series Intake & Exhaust valves - stock size

Ferrea 6000 series valve springs & collets

Titan Motorsports Adjustable Cam Gears (210N’s)

Sound Performance SP5557 CEA Turbocharger - bolts to stock manifold.

Aeromotive AFPR Kit

RC 550CC Injectors

AEM v2 Engine Management from Driftmotion

AEM 3.5bar MAP sensor & IAT

IS300 Coil Packs x 3

That's about it for now - how about you guys? Opinions/thoughts?

Here it is, sitting in a garage, on an rubber backed carpet (don't want it rotting away on the damp concrete!):

Now that my financial situation is vastly improved, and more stable than before, i've made the decision to do a proper engine build, from the block up, rather than just a top end rebuild - which i'm still not entirely happy with. It'll take a long time - at least two years, to get all the parts together, but i'm taking a leaf out of JDMMA70's book - don't rush the build, don't skimp on parts or machine work, do it slowly as i can afford it.

The chassis will need work doing to it as well, although now i'm back in the UK, getting friends round to give me a hand will be much, much easier. Even the fact i have a CHOICE of machine shops within 20 miles of me is a damned luxury, compared to rural france. Welding will be required on the front drivers side strut tower, something i hadn't noticed before - and the rear drivers side outer arch section will need some work doing to it. Not happy about the emergency patch welds on the inner arches either, will have to sort those out as well - just hand me a MIG welder and i'll be off for a week

So - how does the engine stand at the moment? Well, in the process of stripping it down and determining it's condition. Head has been skimmed by 0.019" (0.48mm) in the past, and has a good finish on it. Was used with an HKS Bead type headgasket - something i gather is like finding rocking horse poo now. The only slight concern, is the fact a lot of the exhaust studs were replaced with helicoils (engine BHG'ed in the distant past), and another stud chewed up the head when i was stripping it down. I do have another two heads on potential standby, thanks to JDMMA70's texas contacts. Gasket has very little use on it as well, and it's in good condition, so i'll be more than happy to re-use it once i've stripped off all the viton. Took the head through the local jetwash, too, and it came up a treat - barely any varnish, it's been well maintained, this engine.

The rotating assembly still spins freely, despite not having been run for a few years, the bores are mostly clear of rust, although theres a little bit of surface rust and pitting on cylinder #2, nothing too bad.

So, what's the plan, overall? Well - i like the phrase 'go big, or go home'. But it's not going to be a mega-hp build, but aiming for a comfortable 450rwhp, which is about right, for the chassis - i don't want the back end stepping out on me, and in almost constantly damp/drizzly england, grip is not something that is abundant for 6 months of the year. I'm being absolutely meticulous with this -everything that comes off is labelled, bagged and tagged.

Machine Work:-

Cylinder Head Checked for Surface Hardness - if it's annealed, keep the shims, bin it. ** TOP PRIORITY **

If it checks out okay, then;

Drill out & Helicoil Exhaust Stud #6 with 7/16 kit from DM.

Thoroughly clean, remove all traces of viton from head surface with Acetone

Check & Machine valve seats per TSRM spec

Polish & de-burr camshaft lobes, check for minimum height.

Port & polish the head (do that myself with a dremel, die grinder etc)

Port & polish the inlet & exhaust manifolds, give the exhaust manifold a thermal coating (any recommendations?)

Get block magnafluxed to check for fracturing

Clean Block thoroughly, remove rotating assy. & have bores checked for ovalling & crosshatch, if possible, avoid boring, just re-hone.

Have the block surfaced to remove no more than 0.15mm material, preferably to an RA of 30 or better.

Get crankshaft checked for oval journals, polish regardless. Plastigage clearances with stock rods & bearings, replace with new.

Balance whole rotating assembly.

Components:-

Full Toyota OEM Engine Gasket Set

Plastigauge - lots of it!

Permatex Assembly Lube

ARP Head Stud Kit

ARP Main Stud Kit

ARP Rod Stud Kit

ACL Duraglide bearings & thrust washers

Eagle Rods

CP Pistons

Ferrea 6000 series Intake & Exhaust valves - stock size

Ferrea 6000 series valve springs & collets

Titan Motorsports Adjustable Cam Gears (210N’s)

Sound Performance SP5557 CEA Turbocharger - bolts to stock manifold.

Aeromotive AFPR Kit

RC 550CC Injectors

AEM v2 Engine Management from Driftmotion

AEM 3.5bar MAP sensor & IAT

IS300 Coil Packs x 3

That's about it for now - how about you guys? Opinions/thoughts?