I was just wondering after reading that post on here of that kid paying 10,000 for one. LOLmk3forme said:oh I dont know. a grand or so.:biglaugh: Let me know im in for that price

Ways to cure 7M oiling issues

- Thread starter williamb82

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heres what I did.

I made a -10 alunimum hard line with a flare at one end and a half inch comnpression fitting at the other end. I dilled the stock (BSP) compression fitting out to match 1/2 NPT pipe size. I didnt want to risk getting chips in my already built motor or possibly cracking the block like "Adjuster" did.

heres a photo of the pipe.

I cut the compression ring off of the stock tube and drilled out the stock nut so the bigger aluminum hard line would fit in it and compress the 1/2 inch compression ring

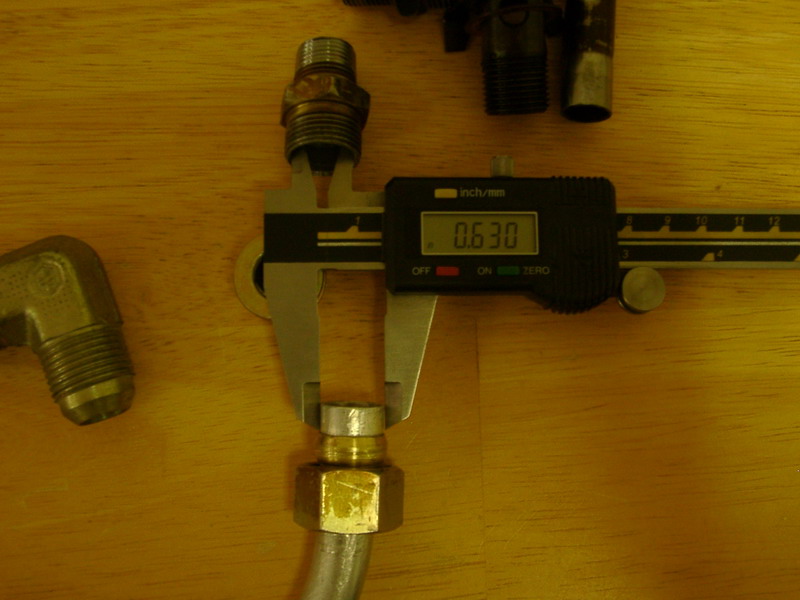

heres a photo of all the measurements starting with the stock measurements.

^^^this would prove to be the smallest diameter in the whole stock plumbing^^^

^^^killing 2 measurments with 1 photo^^^

Notice above the stock compression fitting is the smallest diameter. These holes for the Banjo bolt would seem to be another limiting factor but there are 4 holes at .27 diameter this equals .2288 in sq area, it could be argued that the flow thru the banjo fitting is the real limiting factor but the inside diameter of the pipe at .444 dia has an area of .1548 sq in.

Here are all the numbers for the parts I modified.

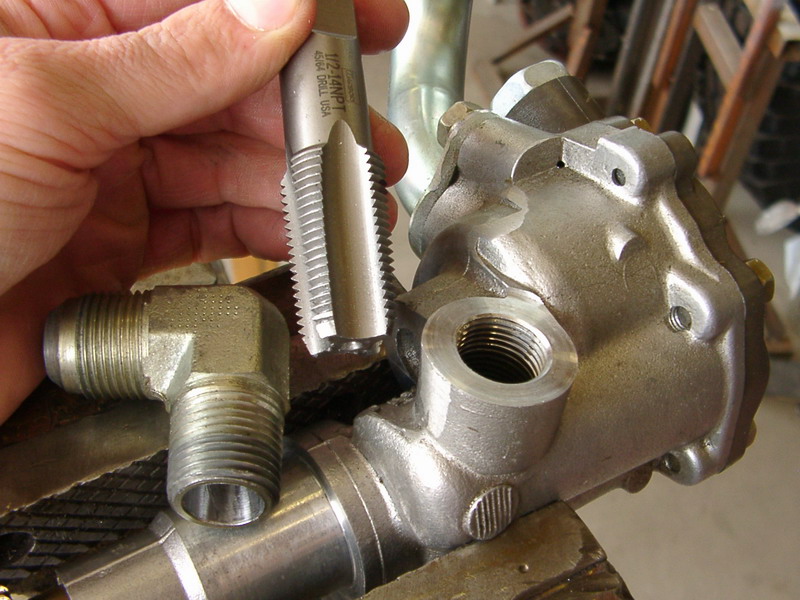

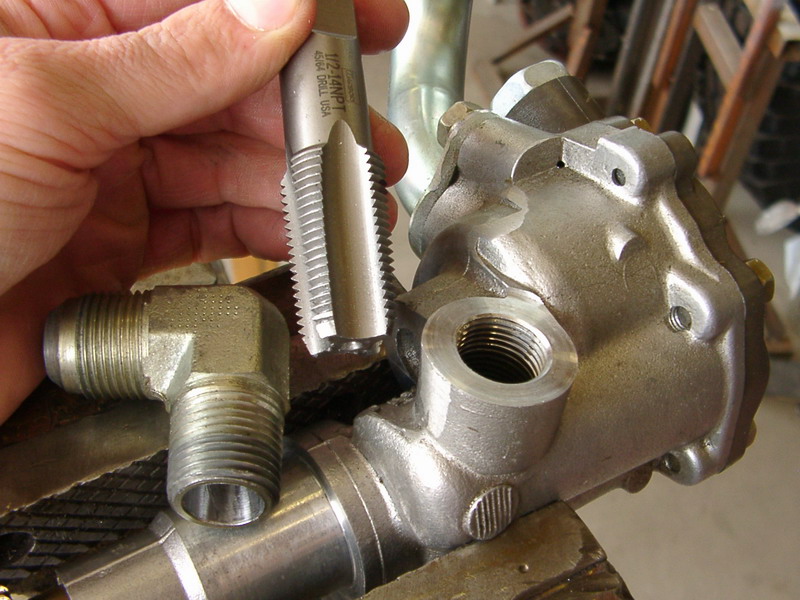

This is the diameter of the fitting I drilled out.

Killed another 2 birds with 1 photo

This .504 dimension above appears to be the minimum diameter now, this diameter has a sq area of .1995 inches for a difference of .0447 sq in. The numbers dont appear to be so big but it works out to a 29% increase in square area between the pump and the filter.

Following are some more photos for comparison sake.

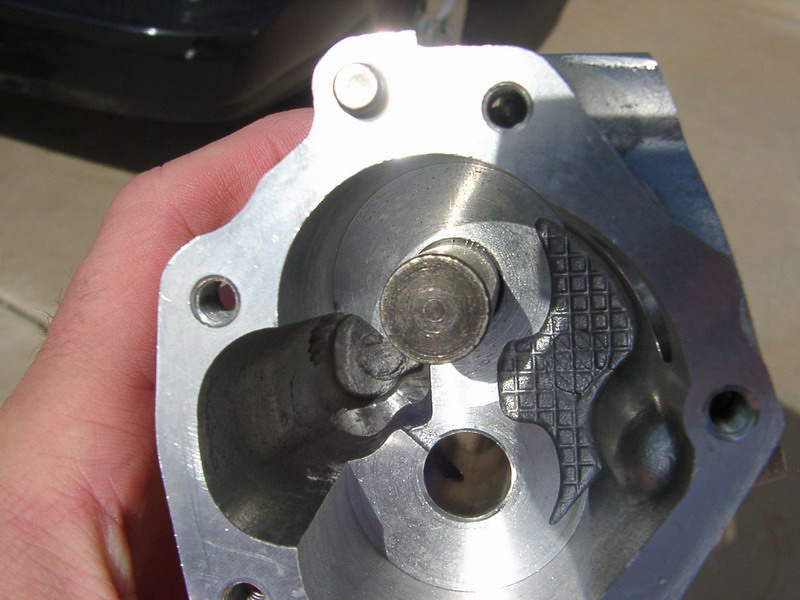

I disassembled the new oil pump I washed and degreased it thuroghly

I was very surprised to find this.... see below

^^^do you see what I see^^^ This is a new Toyota pump purchased from the dealership.

I got them out with a pick, but they were so small I lost a few.

I had to measure them for posterity.

I made a -10 alunimum hard line with a flare at one end and a half inch comnpression fitting at the other end. I dilled the stock (BSP) compression fitting out to match 1/2 NPT pipe size. I didnt want to risk getting chips in my already built motor or possibly cracking the block like "Adjuster" did.

heres a photo of the pipe.

I cut the compression ring off of the stock tube and drilled out the stock nut so the bigger aluminum hard line would fit in it and compress the 1/2 inch compression ring

heres a photo of all the measurements starting with the stock measurements.

^^^this would prove to be the smallest diameter in the whole stock plumbing^^^

^^^killing 2 measurments with 1 photo^^^

Notice above the stock compression fitting is the smallest diameter. These holes for the Banjo bolt would seem to be another limiting factor but there are 4 holes at .27 diameter this equals .2288 in sq area, it could be argued that the flow thru the banjo fitting is the real limiting factor but the inside diameter of the pipe at .444 dia has an area of .1548 sq in.

Here are all the numbers for the parts I modified.

This is the diameter of the fitting I drilled out.

Killed another 2 birds with 1 photo

This .504 dimension above appears to be the minimum diameter now, this diameter has a sq area of .1995 inches for a difference of .0447 sq in. The numbers dont appear to be so big but it works out to a 29% increase in square area between the pump and the filter.

Following are some more photos for comparison sake.

I disassembled the new oil pump I washed and degreased it thuroghly

I was very surprised to find this.... see below

^^^do you see what I see^^^ This is a new Toyota pump purchased from the dealership.

I got them out with a pick, but they were so small I lost a few.

I had to measure them for posterity.

Last edited:

Heres all the numbers again in one place

Smallest diameter in the stock system .444 dia has an area of .1548 sq in.

New smallest diameter in my design .504 dia has an area of .1995 sq in.

Difference of .0447 sq in. This equals a 29% increase.

After thuroghly diving into the stock lubrication system I am amazed more 7M's dont suffer the dreaded rod knock fate. From the stupid oil pump bypass spring to the spring pressure of the oil squiters to the oil cooler itself I am blown away they would think this is sufficent.

Im sure it has been covered before but I wanted to state it again in as few words as possible.

The stock oil cooler is a piss poor excuse for an oil cooler. The way it is designed is, if there is an over pressure between the pump and the filter some oil is bled out into the cooler and returned to the oil pan, so basically your oil gets cooled when your oil bypasses the filter and barely cools the engine at all. When your oil is the hottest and thinest it will never see the oil cooler.

It should also be mentioned that an off the shelf (joe blow consumer AN fitting, as opposed to an actual military spec AN fitting) -10 AN fitting will never have the same inside diameter as each other. I had a box full of -10 AN fittings and they all had a little different inside diameter some even had a smaller inside diameter than .46 inches. The ones I did use (coming out of the oil pump) I had to drill out to get them over .5 inch inside diameter. Just thought I should share that.

Last edited:

all I can say is wow ARZ! Your talents obviously go farther than brakes! That is beautiful work. Well thought out! Im PM'ing you.

woohoo 7 of those oil squirter bolts w/springs left in the us. and I just took 6 of them  for a lovely 50 bucks.

for a lovely 50 bucks.

QWIKSTRIKE

475rwhp459torq an climbin

Arz so far has the best design.A pipe of hard metal rather than braided hose is so much more comforting.Also more of a fail safe design:biglaugh:

Last edited:

I agree. I would feel much less concern with a hard pipe vs a hose, braided or not. Also Arz I was wondering what is the ID of the new 90 coming out of the oil pump. I didnt see a measurement on that. Looks like it might be smaller than everything else. Hard to tell for sure by pics though.

Last edited:

Yea I did have a photo of that but for some reason I didnt post it. I will tonight. But if you remember I did say that some AN fittings were smaller than .5 inch inside dia, that was one of them, notice in the photo below I drilled that out to a little bigger, it was still bigger than the .504 found in the stock fitting I drilled out.

EDIT: here you go is this what your looking for?

EDIT: here you go is this what your looking for?

Last edited:

Also Andy I was wondering. Im sure aluminum is probaby cheaper and lighter but couldnt you also use copper tubing? I think the walls would be a bit thicker and make bending into shape a bit more of a challenge. Is there any issues with oil and copper? Maybe it wouldnt be a good idea to add another type of metal to everything in our motors now? It seems alot of the round gaskets on banjo bolts and such are copper. I dunno, just a thought.

JustAnotherVictim

Supramania Contributor

I lost my engine due to rod knock. I know it was more my fault than anything. So, I am rebuilding and I would really like to prevent oil starvation in my new engine because I will be road racing it.

I have ordered a new oil pump. Should I also get the oil squirter bolts? Can someone confirm the part number for these?

I've been looking for something that can be easily done to improve oil pickup. I've heard about people dropping the oil pump pickup maybe 1/4 to 1/2 an inch. One guy said that he just bent the pipe to lower it. Does anyone have an experience doing this? What would I need to do?

I have ordered a new oil pump. Should I also get the oil squirter bolts? Can someone confirm the part number for these?

I've been looking for something that can be easily done to improve oil pickup. I've heard about people dropping the oil pump pickup maybe 1/4 to 1/2 an inch. One guy said that he just bent the pipe to lower it. Does anyone have an experience doing this? What would I need to do?

Yea Im looking into having them made out of Stainless. Yea I know copper reacts with fuel and they do use it for the seals on fuel lines and banjo fittings but I dont want to use it as a conduit. That would be kinda ghetto. Copper is for houseold plumbing not Hotrod plumbing.

I will keep you posted.

Im working on it as we speak. I have the models at my machinist. I have designed a complete BOLT ON system. I hate the buy this then buy that design. It will obviously look a little different but you wont have to tap anything you will just bolt on my custom parts and you too will see about a 30% increase in area also.JustAnotherVictim said:A kit maybe Andy??

I will keep you posted.

Oh Andy I hope you come up with something soon. I can't wait much longer. Any ideas at all on price and availability?

Turbo. Targa. Life.

SupraMania Shirt Slinger!

Any time frame on this possible kit Andy? I dont mean to sound inpatient but im inpatient.:naughty: Also any idea on price. My budget is already shot so im trying to guage what I can and cant get by with. Thanks

Sorry but no, all of my contacts were on holiday today.

Im sorry but I dont have a price either but I cant quote anything until I get quotes back from the CNC tube bending guy.

Even if they are high I will still make the tubes myself. I found some stainless tubing and my buddy had dies so I was able to make some test parts and am waiting on quotes from the CNC bender guy before I comit to doing them myself.

Im sorry but I dont have a price either but I cant quote anything until I get quotes back from the CNC tube bending guy.

Even if they are high I will still make the tubes myself. I found some stainless tubing and my buddy had dies so I was able to make some test parts and am waiting on quotes from the CNC bender guy before I comit to doing them myself.