So most of you guys know my story last year, about my diff and steering centering. Well I finally settled my steering rack centering and got a full alignment and tire balancing and the car is going straight now. However, since I thought the car is ok now, I opened up the throttle and went up to 70mph, and found that the car vibrates at anything over 60mph. The vibration seems to be coming from underneath and the rear, and I can feel it through the doors too.

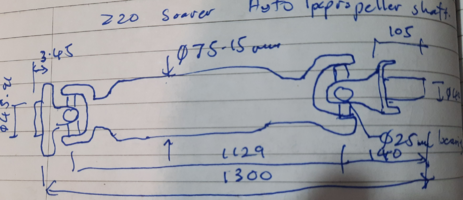

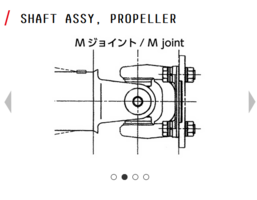

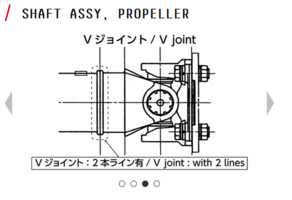

My first suspicion is the propeller shaft. It was rebuilt by some idiot who calls himself a pro. Why do I suspect the prop shaft? Well because he rebuilt it with new U joints with grease zerks, yet I do not see any additional weights welded to the tubings, which mkes me suspect that the centering might be slightly off and balancing was not done.

Has anyone encountered a similar issue like mine ?

There is a week long holiday next week, I found some else nearby who says he can center and balance the prop shaft, but he will only open shop end of next week. Gonna send the prop shaft to him to check it out.

My first suspicion is the propeller shaft. It was rebuilt by some idiot who calls himself a pro. Why do I suspect the prop shaft? Well because he rebuilt it with new U joints with grease zerks, yet I do not see any additional weights welded to the tubings, which mkes me suspect that the centering might be slightly off and balancing was not done.

Has anyone encountered a similar issue like mine ?

There is a week long holiday next week, I found some else nearby who says he can center and balance the prop shaft, but he will only open shop end of next week. Gonna send the prop shaft to him to check it out.