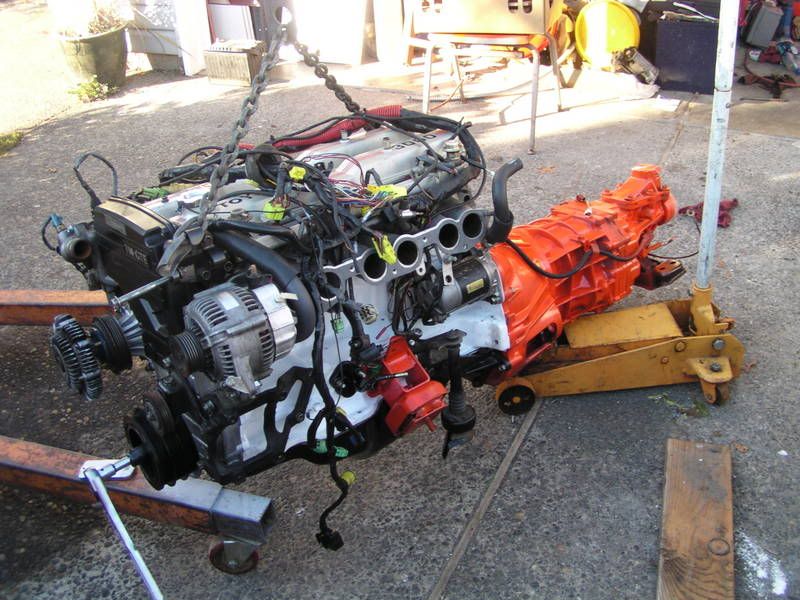

Okay so here's an update!!! Things have been comming along slowely I suppose, atleast its almost there right? So the pictures I will be showing you today is where the motor is at now, explaining what left needs to be done, full view of our mess.. or our beauty? whatever you want it to be.. And LAST of all, Detailed pictures on how to get RID of your Tripod/Cruise control and have a Direct throttle to throttle body connection that

WORKS.

These are high res. pictures scaled down to 640 so be happy.. They were 3265x whatever =P

Okay, so any ways.. Here's the current status of the motor. It's in, it's bolted down in there and every thing, coil packs are mounted below the intake manifold (sorry.. pics are on the other digital camera).. Radiator is in aswell as the turbo and every thing like that.. What needs to be done now is replace a broken knock sensor, install intake manifold and upper IC pipes, ground some connections and fix a broken wire. the car isn't throwing any codes like jim said, so thats good.. Looks like I have a good platform to work with!

Next off is a full shot, yepp.. that's a full shot if you're blind. Just kidding! Here's what the car has looked like infront of our messy house for the last unno weeks! Like my discontinued rims huh? :icon_bigg

Just because this picture turned out cool looking, here's my interior. I know, brown seats, blue accent peices, black dash!? Doesn't fit! I KNOW! lol, thats how I bought the car.. I don't care! :cry:

Okay, last of all for now *until I can upload more pictures or take more*... Here's a step by step of the throttle connection. Btw, you need turbo throttle body linkages, and an N/A throttle cable and some knowledge of how to use a grinder, a drill, and maybe some pliers.

(1) First off, we start with a stock stopper peice from the throttle body. This peice is used JUST for the stopper and springs so the throttle closes and opens perfect and will not throw codes for over opening. The red line is where the peice was cut in later pictures for clearance issues.

(2) Next, this peice i BELIEVE came off of a turbo, DONT quote me! I didn't see where jim pulled it off before he cut into it. But, any ways.. This peice is where the throttle cable will attach to, it has been cut as you can see. (used a grinder..)

(3) Here is peice number one and two put together.. showing how we fit them.

(4) Fourth, here is part number 1 mounted on the throttle body before it was cut for mounting purposes. We took pictures as we were figuring out how to get it to work.

(5) Fifth, Part number one mounted still but with the two stock springs hooked up.

(6) Sixth, this shows part one and two mounted on the throttle body with the springs attached.

(7) Seventh, this is all the peices mounted to the throttle body, after part one was cut for clearance issues. You can see in the picture we bent a peice of metal and cut some holes in it to hold the cable in a stationary position. Don't worry! We will be making a new peice that is longer and places the cable straight with the guide so there isn't any problems, this was purely mock up!

(8) Eighth, this is just a different view of picture 7. Showing the cut part number 1.

(9) Last of all! Another view of the mock up with all of the springs attached.

Hope you all enjoyed reading this, if someone wants to take the initiative to post a "how to do it" for this throttle linkage go ahead you can use my pictures and information, but give me credit for doing this writeup in your thread :icon_bigg