Holset doesn't specify a restrictor for pressures under 72psi. They do specify a much larger drain than -10AN though, so maybe go with a -3AN feed line, or a .100" restrictor to cut down flow a bit. Not too small though, or you'll seize it..

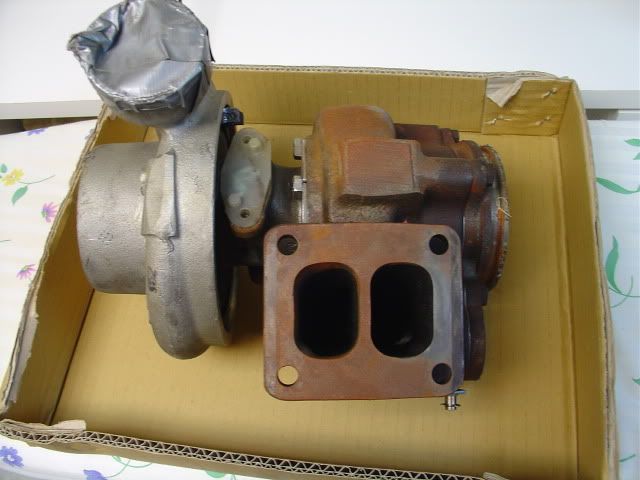

Found this on another forum, it's direct from the Holset HX35 repair manual.

8. Normal oil temperature is 95+/-5°C (203+/-9° F). It should not exceed 120°C (248°F) under any operating condition.

9. Any pre-lube oil must be clean and meet the minimum CD classification.

10. The orientation of turbine housing, bearing housing and compressor cover is fixed according to application. During installation, do not attempt to rotate these components. Inclined turbocharger installation is not recommended. If an installed angle is necessary, oil inlet centreline must be +/- 10 degrees from vertical and rotor centreline +/- 5 degrees from horizontal.

11. Holset permits oil return pipes to decline at an overall angle of not less than 30 degrees below horizontal.All turbocharger applications require a pipe of internal diameter greater than 19 mm which has integrated connectors. To ensure oil returns into the engine under all operating conditions, the return connection into the engine sump must not be submerged and the outlet flange of the turbocharger must be 50 mm above the maximum oil level of the engine sump pan. Crankcase pressure should be limited ideally to 0.8 kPa (0.12 lbf/in2) but 1.4 kPa (0.20 lbf/in2) can be accepted by reference to Holset.

12. Oil pressure of 150 kPa (20 lbf/in2) must show at the oil inlet within 3 - 4 seconds of engine firing to prevent damage to turbocharger bearing system. A flexible supply pipe is recommended.

13. The minimum oil pressure when the engine is on load must be 210 kPa (30 lbf/in2). Maximum permissible operating pressure is 500 kPa (72 lbf/in2) although 600 kPa (88 lbf/in2) is permitted during cold start up. Under idling conditions pressure should not fall below 70 kPa (10 lbf/in2).

14. Recommended oil flows for the turbochargers are 2 litre/min at idle and 3 litre/min above maximum torque speed.