The Fruition of Obsession -- 310,000 mile makeover --

- Thread starter suprarx7nut

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Driven near 200 miles on the new harness. A few minor problems, but nothing huge. I had a short scare with the damn CF sheathing. I had a 12V ignition wire splice exposed while doing initial testing and started to smoke/burn some tape. Cut the Carbon Fiber off the next day. My oil gauge wire for some reason isn't getting a signal, so I made another splice into the ECU wire. I'm getting a code 42 for speed signal to ECU. I'm not sure what's going on. It's a simple wire from the ECU to a body connector. The terminations look ok, but I still get the code every now and then.

My diagnostics dash switch is great. I didn't know you can check codes with the engine running! It's brilliant. If I get a code, I can pull over or just wait for the next stop light. Hit the switch, check the code, hit the switch again. No need to get out, open hood or even turn off the engine!

I'm also loving the look of the new tires. Really makes a difference in the appearance. Now it just needs to be lowered, haha.

I think my next immediate project (aside from finishing up a lot of minor touches and maintenance) will be to convert the A/C to 134. I haven't had good solid A/C for a year now and it bothers me.

WIRING TIDBITS:

FiberGlass Insultherm high temp sheathing for main section which crosses over engine:

Had to de-pin nearly every connector and tape up the wires so the sheath can fit over:

Carbon Fiber. Looks nice when it's perfect, but turns out to be a horrible choice for this project:

Good donor harness on left, New harness middle, old, shitty harness right

EFI Resistor, relocated to where ABS and charcoal normally reside.

Sensors on water neck area. I integrated a custom bracket into the harness with integral grounds. The bracket is mostly hidden within the sheathing.

Grounds in the mounting point of the bracket:

ECU side before final cleanup:

Damn carbon fiber again...

Main section of connectors under the intake plenum:

Another view:

Finally, I corrected my stereo wiring using proper splice crimps, good crimper, heatshrink.

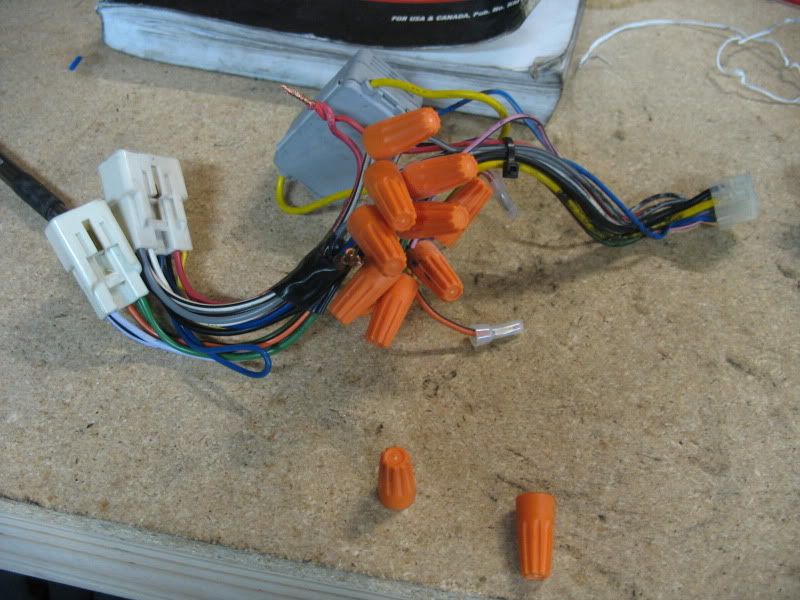

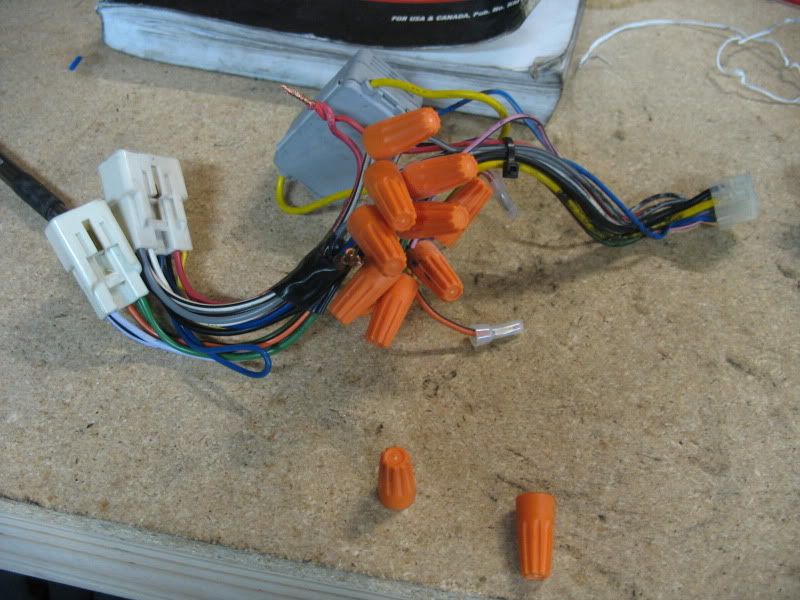

Before:

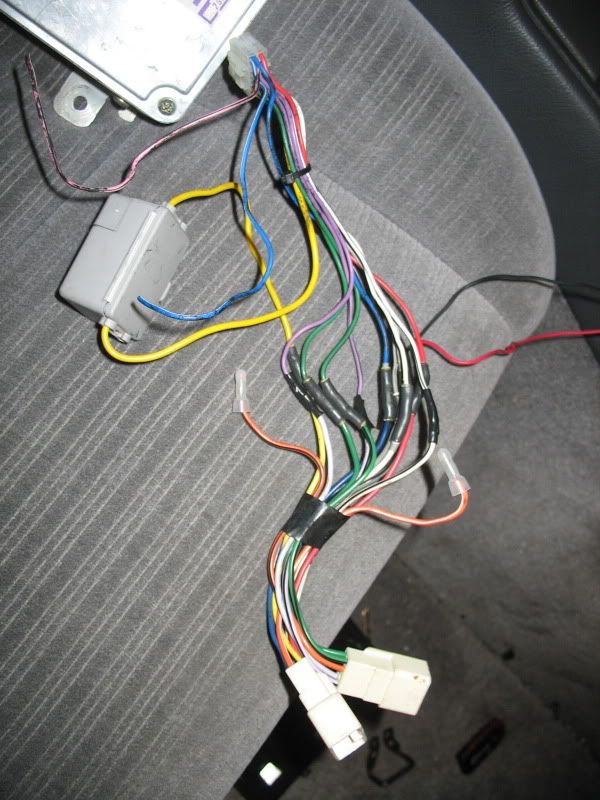

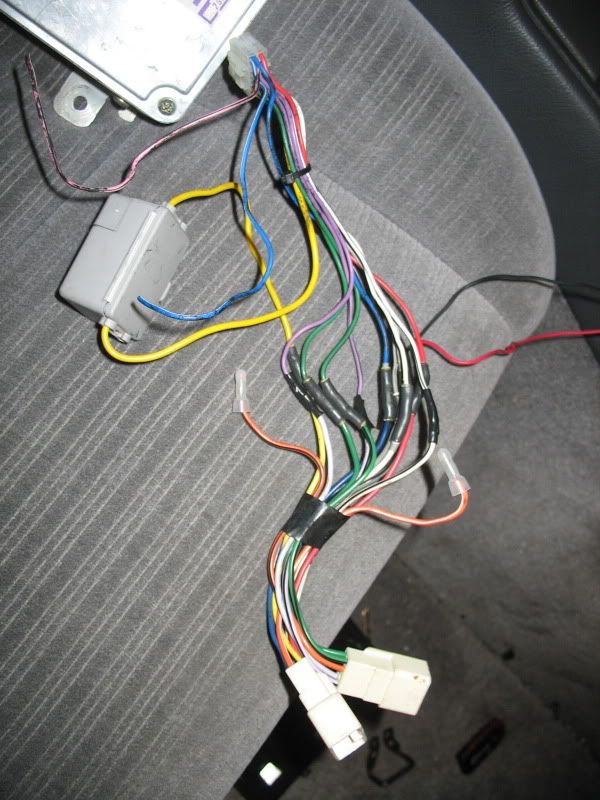

After:

Total Cost of the harness: ~$1000~1200 in parts, more if you include the purchase of special tooling

Wire: $350-400, I used 16 and 12 AWG. Most factory wiring is closer to 18-20 with a few closer to 14 AWG.

Sheathing/heatshrink: ~$300

Terminals: $200+

Connectors: $250+

I could have saved some $$ by not ordering so much extra materials, but it was very difficult to estimate the correct amount.

Total research time: 40-60 hours maybe?

Total labor time: 50-100 maybe?

Calendar time: 5 months.

Worth it? I'd say yes. It was a HELL of a project. I'd rather do multiple engine builds before doing it again though. It's a LOT of work just to get the car to run the way it should have been running.

My diagnostics dash switch is great. I didn't know you can check codes with the engine running! It's brilliant. If I get a code, I can pull over or just wait for the next stop light. Hit the switch, check the code, hit the switch again. No need to get out, open hood or even turn off the engine!

I'm also loving the look of the new tires. Really makes a difference in the appearance. Now it just needs to be lowered, haha.

I think my next immediate project (aside from finishing up a lot of minor touches and maintenance) will be to convert the A/C to 134. I haven't had good solid A/C for a year now and it bothers me.

WIRING TIDBITS:

FiberGlass Insultherm high temp sheathing for main section which crosses over engine:

Had to de-pin nearly every connector and tape up the wires so the sheath can fit over:

Carbon Fiber. Looks nice when it's perfect, but turns out to be a horrible choice for this project:

Good donor harness on left, New harness middle, old, shitty harness right

EFI Resistor, relocated to where ABS and charcoal normally reside.

Sensors on water neck area. I integrated a custom bracket into the harness with integral grounds. The bracket is mostly hidden within the sheathing.

Grounds in the mounting point of the bracket:

ECU side before final cleanup:

Damn carbon fiber again...

Main section of connectors under the intake plenum:

Another view:

Finally, I corrected my stereo wiring using proper splice crimps, good crimper, heatshrink.

Before:

After:

Total Cost of the harness: ~$1000~1200 in parts, more if you include the purchase of special tooling

Wire: $350-400, I used 16 and 12 AWG. Most factory wiring is closer to 18-20 with a few closer to 14 AWG.

Sheathing/heatshrink: ~$300

Terminals: $200+

Connectors: $250+

I could have saved some $$ by not ordering so much extra materials, but it was very difficult to estimate the correct amount.

Total research time: 40-60 hours maybe?

Total labor time: 50-100 maybe?

Calendar time: 5 months.

Worth it? I'd say yes. It was a HELL of a project. I'd rather do multiple engine builds before doing it again though. It's a LOT of work just to get the car to run the way it should have been running.

Last edited:

CyFi6;1835868 said:Nice work man! Post pics of everything on the motor.

Going to the junkyard today to fit a smaller cc in the fender. I'm putting off the final bay pic until that's in place.

Don't want people thinking I'm going to keep it without a cc.

Sent from my ADR6400L using Tapatalk 2

suprarx7nut;1833243 said:RE: EasternBeaver: It's intended to be for motorcycle repair, so I doubt he really cares what car parts it happens to overlap with. There are a couple connectors you can find on there, but not many. If you're looking for one (or ten particular connectors I can tell you who has them. I was unable to find a dozen or so, but I did manage to track down a vendor for most terminals and connectors.

I'll eventually post a good reference sheet, but not now. Too much actual car work to be done!

I've been doing a lot of wiring harness repair recently, and following your thread pretty closely. What are these other vendors you speak of? My local Toyota dealership didn't have any of the knowledge/books needed to find the right housings and terminals. Actually, I'd love to start compiling at list of what type of connector and where you can source them for an entire 7M harness, but that sounds like a winter project...

Any advice you could offer?

emiliorescigno;1852614 said:I've been doing a lot of wiring harness repair recently, and following your thread pretty closely. What are these other vendors you speak of? My local Toyota dealership didn't have any of the knowledge/books needed to find the right housings and terminals. Actually, I'd love to start compiling at list of what type of connector and where you can source them for an entire 7M harness, but that sounds like a winter project...

Any advice you could offer?

I can offer my list of part numbers and such.

View attachment Auto Records - Master.pdfView attachment Auto Records - Connectors.pdf

Let me know if you want the excel file and I can email it. I dont have a great list compiled of all the vendors, but I have all the info saved. Let me know if you're looking for a particular one and I can help out.

Off hand the following were not available anywhere I found.

O2 sensor

TPS (driftmotion has a usable replacement)

M1 connector by the ECU. I replaced with a standard non-sealed MT-90 terminal from Eastern Beaver.

In my attached sheet, (far left column) the green were all available from Toyota. The white were not. The "TODC" terminal I determined to basically be bullshit. The ones they label as TODC are different from each other and I couldn't find a corresponding "TODC" terminal from Tyco, AMP, Sumitomo, or any other vendor. I found many terminals through New United Race Tech. Justin helped me a bit. I ordered about $100 in terminals I didn't need but sometimes you've just gotta use good old trial and error.

Again, if you have specific ones let me know. Unfortunately, I dont have a fully complete master document made up.

Wow - WOW! That is awesome to see all the connectors and Toyota part numbers for each one. For now I'm "refreshing" my harness and connectors that are all on the water neck area of the car. (O2, CPS, AFM, 5 Temp Sensors)

The rest of my harness is in pretty spiffy condition and I would hate to chop it up like so many people seem to do.

Regarding the O2 sensor, my housing is in fine condition but one of the wires is broken, so I'll hopefully be able to skate by with just de-pinning and crimping on new terminals. Thanks again for such awesome info!

The rest of my harness is in pretty spiffy condition and I would hate to chop it up like so many people seem to do.

Regarding the O2 sensor, my housing is in fine condition but one of the wires is broken, so I'll hopefully be able to skate by with just de-pinning and crimping on new terminals. Thanks again for such awesome info!

emiliorescigno;1852659 said:Wow - WOW! That is awesome to see all the connectors and Toyota part numbers for each one. For now I'm "refreshing" my harness and connectors that are all on the water neck area of the car. (O2, CPS, AFM, 5 Temp Sensors)

The rest of my harness is in pretty spiffy condition and I would hate to chop it up like so many people seem to do.

Regarding the O2 sensor, my housing is in fine condition but one of the wires is broken, so I'll hopefully be able to skate by with just de-pinning and crimping on new terminals. Thanks again for such awesome info!

No problem. I wish it was more complete. It's probably 75-90% there, but there are still some gaps.

Good luck finding those TODC terminals for the O2 connector. If you have trouble, send me a pic and I'll check if I ever got any of those. maybe I can give you the link for them through New United Race Tech.

suprarx7nut;1852662 said:Good luck finding those TODC terminals for the O2 connector. If you have trouble, send me a pic and I'll check if I ever got any of those. maybe I can give you the link for them through New United Race Tech.

I've been looking over all this info and getting a little "wish list" together for myself. My only major stumbling block is the terminal that's used for the Radiator Cooling fan switch/Knock sensors. Did you ever find a terminal that works with those connectors? Other than that, I have found just about every piece of information I've been looking for.

The parts guy at my Toyota dealership is going to lose his mind when he sees the list of part #s I'm asking for!

emiliorescigno;1852675 said:I've been looking over all this info and getting a little "wish list" together for myself. My only major stumbling block is the terminal that's used for the Radiator Cooling fan switch/Knock sensors. Did you ever find a terminal that works with those connectors? Other than that, I have found just about every piece of information I've been looking for.

The parts guy at my Toyota dealership is going to lose his mind when he sees the list of part #s I'm asking for!

Here ya go! They call them the "SSC" series from Tyco/Amp

Terminals:

http://www.newunitedracetech.com/shop/ssc-terminals-c-1_15_16.html?zenid=pgagigbp3bkucr1v9v1bh5vfd3

Housings: (one or two are found on the water neck, but I dont recall which ones. Just have to match up the notches)

http://www.newunitedracetech.com/shop/ssc-housings-c-1_15_24.html

I'd strongly, strongly suggest going through Champion Toyota unless your local dealer can REALLY hook you up. Champion was roughly 25-40% cheaper than my local dealers.

Update!

Ordered 50 trim polished and coated CT-26 from Aaron @ Driftmotion. Also ordered the gasket kit for the CT, softline kit from ARZ, new battery tie down, and new hatch struts. Once the turbo gets installed the next big project is the A/C system retrofit to 134!

Ordered 50 trim polished and coated CT-26 from Aaron @ Driftmotion. Also ordered the gasket kit for the CT, softline kit from ARZ, new battery tie down, and new hatch struts. Once the turbo gets installed the next big project is the A/C system retrofit to 134!

50 trim arrived today. Old Ct removed, softline prepped on new turbo. Good stuff.

Old:

I got 2 copper washers and 1 steel washer. :dunno: AND I got an extra AN-adapter fitting. I assume I just need to use one crush washer. I guess Aaron was just feeling generous, lol.

The old turbo has a large amount of front to back axial play. Approx 1mm. Spec is 0.13mm so it's DEFINITELY in need of rebuild.

Old:

I got 2 copper washers and 1 steel washer. :dunno: AND I got an extra AN-adapter fitting. I assume I just need to use one crush washer. I guess Aaron was just feeling generous, lol.

The old turbo has a large amount of front to back axial play. Approx 1mm. Spec is 0.13mm so it's DEFINITELY in need of rebuild.

Hey nice job!! Lovethe build! On your wiring harness I see that you split it. Did you route it on the hot side through the passenger wheel well? I just got through splitting mine with the intent of going the above mentioned route. If you did do you have pics? I also went one step further in routing the cold side as if i had a JZGTE swap by cutting a hole on the drivers side and running that part of the harness inside the car instead of going across the rear of the firewall (well...haven't cut the hole yet). Anyway....thats my plan to sorta clean up my by and your harness is almost exactly what im plan on doing. So any pics of how you ran the harness would be nice.

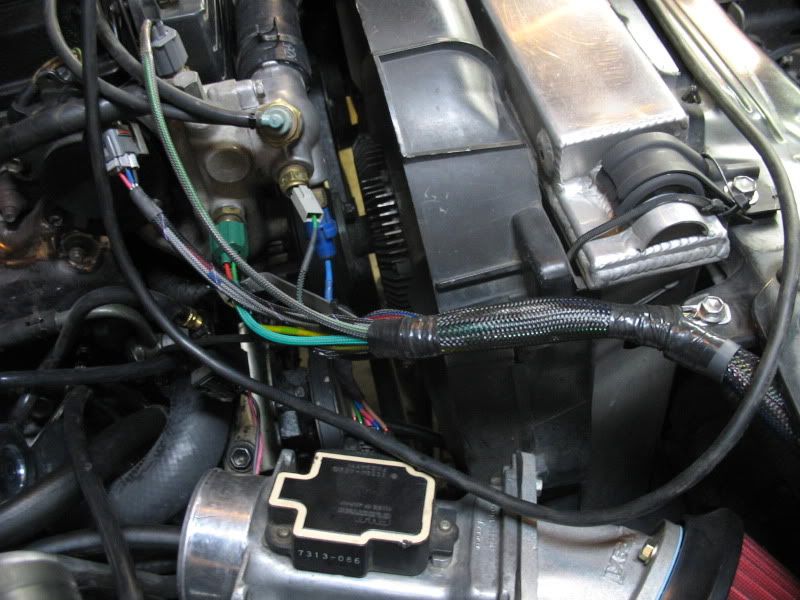

I didn't hide the harness at all. It runs, exposed along the factory routing on the intake side and along the fender corner on the exhaust side. The part going over the engine and nearest the turbo have high heat, coated fiberglass sheathing to help protect it from the heat.

I'm all about function. I didn't want to do a "wire tuck" if it meant anything would be significantly more difficult to access. I just moved a couple components and routed the wire wherever made sense.

I just realized I didn't post completed pictures, lol. Once I get the turbo installed I'll post an updated engine bay pic.

I'm all about function. I didn't want to do a "wire tuck" if it meant anything would be significantly more difficult to access. I just moved a couple components and routed the wire wherever made sense.

I just realized I didn't post completed pictures, lol. Once I get the turbo installed I'll post an updated engine bay pic.

Ok. I wish my split harness came out lookin that nice. I might redo it down the line since i see that it can look nice even if i am trying to wire tuck it. Again......great build. I have enjoyed this build alot.

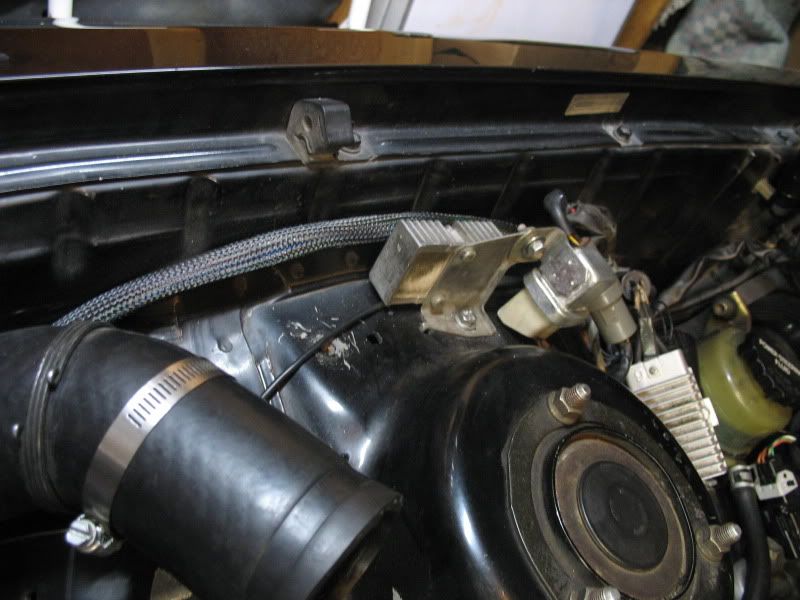

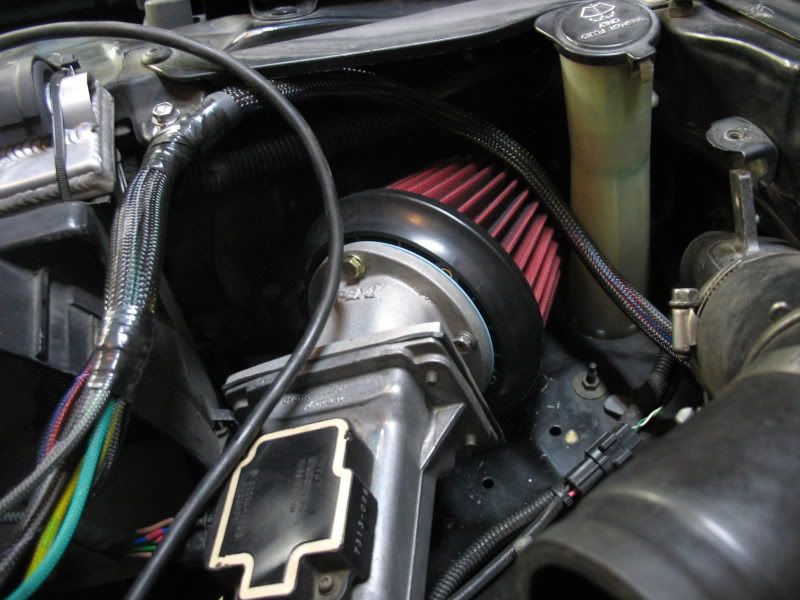

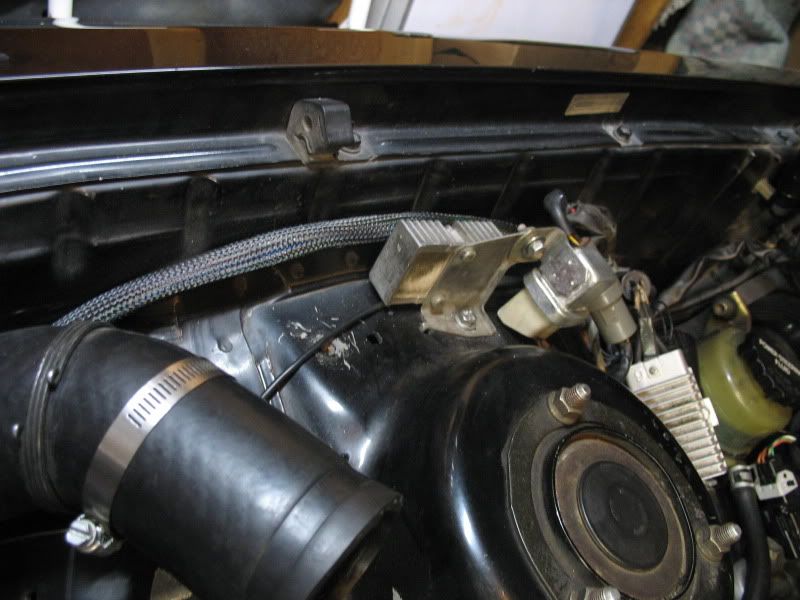

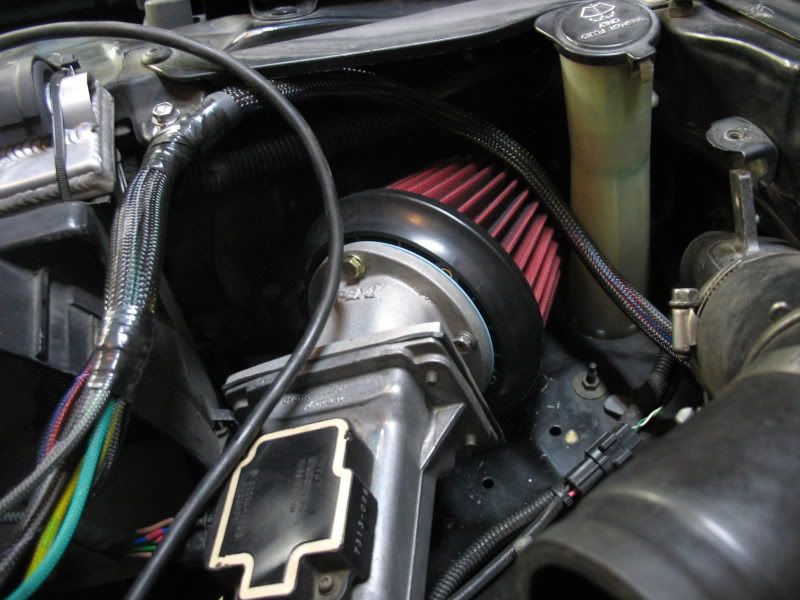

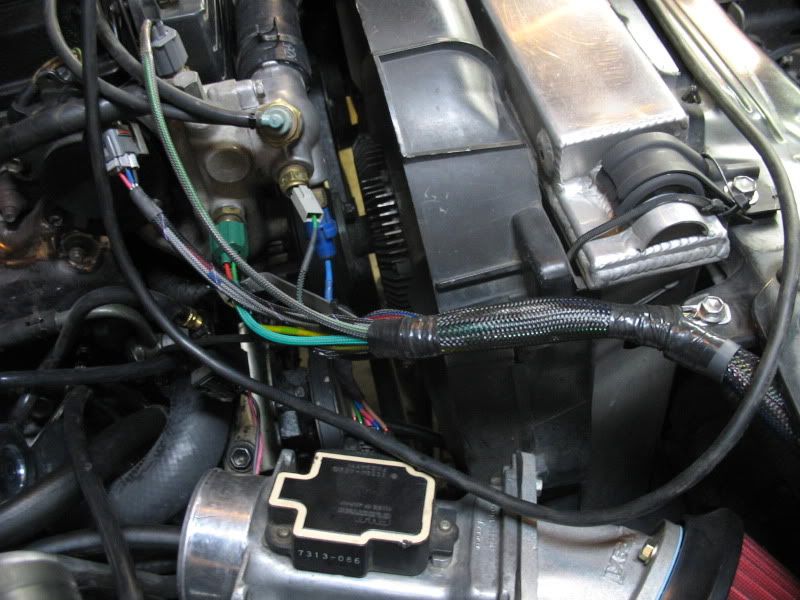

Update pictures. Turbo installed, but haven't started her back up yet.

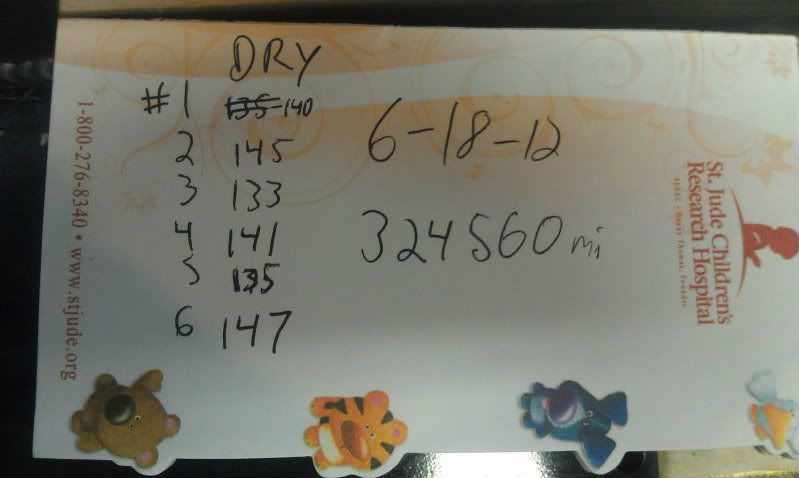

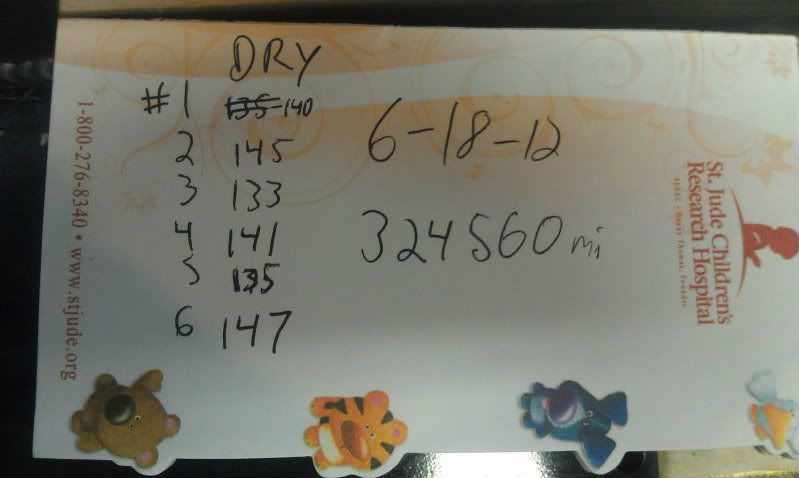

Compression test from a month ago

Polished the roof. Eliminated the clear coat fade with the Mother's powerball. I'd HIGHLY recommend that or a Porter Cable Random Orbital buffer for polishing work. Made it nice and easy.

Stupid hood still looks like shit. I haven't polished it yet because I'm so discouraged by the huge paint chips...

DM Goodies

50 trim Goodness

Absolutely beautiful flanges and AN lines

Wiring harness/Engine bay shots. I still need a goddamn Charcoal Canister. I CANNOT find a smaller compatible one. IF ANYONE HAS A JDM CC I'LL PAY MORE THAN ITS WORTH!!!

Compression test from a month ago

Polished the roof. Eliminated the clear coat fade with the Mother's powerball. I'd HIGHLY recommend that or a Porter Cable Random Orbital buffer for polishing work. Made it nice and easy.

Stupid hood still looks like shit. I haven't polished it yet because I'm so discouraged by the huge paint chips...

DM Goodies

50 trim Goodness

Absolutely beautiful flanges and AN lines

Wiring harness/Engine bay shots. I still need a goddamn Charcoal Canister. I CANNOT find a smaller compatible one. IF ANYONE HAS A JDM CC I'LL PAY MORE THAN ITS WORTH!!!

Just finished retrofitting my AC system. Blows nice and cold.

New compressor

New expansion valve

New drier

New o-rings throughout

680 grams of R134 with UV dye in one bottle

~150-160 ml ester oil

New valve cores

New compressor

New expansion valve

New drier

New o-rings throughout

680 grams of R134 with UV dye in one bottle

~150-160 ml ester oil

New valve cores

1. A/C is absolutely awesome, and every Supra should have it.

2. What were the reasons you went for a 50 trim in favor of a 57 trim?

2. What were the reasons you went for a 50 trim in favor of a 57 trim?

emiliorescigno;1865722 said:1. A/C is absolutely awesome, and every Supra should have it.

2. What were the reasons you went for a 50 trim in favor of a 57 trim?

I only plan on ~350whp max. The 50 trim should be plenty capable of that and will have the least amount of lag and the lowest boost threshold. Sure the 57 trim is the same price, but why get if I'm never going to use it? My whole car is designed to hold ~350 whp at most. Clutch, HG, trans, turbo, injectors, IC, tires are all sized for that power level so if I ever decide to go up in power, it will be a huge change in the car. For now, everything gets sized to ~350 whp.