Im not sure how much power im making but i have a "low mileage" JDM motor/tranny and ive put over 7k miles on it with the mods in my sig and running 9-10 psi. Ive done burnouts and doughnuts, a little drifting(or lack of drifting is more like it) and a few street launches and some interstate racing. Hasnt slipped yet. Of course i havnt been to the drag strip yet either.

stock clutch power capabilities?

- Thread starter suprafanatic

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GrimJack;969730 said:We had 2 guys underneath, one guy one the engine bay, and one guy traded off between sourcing wrenches and working in the cabin.

yeah that makes sense

noone really thinks about it but that guy getting the wrenches for you really helps hehe and lifts

What about the Stage 2 clutch that drift motion offers. Its a stock disk with and upgraded PP? What kind of power is this capable of holding?

Depends on how much you ride the clutch, how far down it's worn, and how hard you shock it when you launch hard.

If it's worn down the disc to the rivets, that will chew up your PP pretty bad. If you ride it all the time, it's going to be cracked, and cracks are bad in a part that spins at high enough velocity to amputate both legs if it ever lets go.

This is why drag racers are required to install a shield after they start getting fast.

Unfortunately, the only way to really know is to pull it and check.

If it's worn down the disc to the rivets, that will chew up your PP pretty bad. If you ride it all the time, it's going to be cracked, and cracks are bad in a part that spins at high enough velocity to amputate both legs if it ever lets go.

This is why drag racers are required to install a shield after they start getting fast.

Unfortunately, the only way to really know is to pull it and check.

i got my clutch installed for 450 out the door.i bought all my own parts tho.suprafanatic;968688 said:haha. ya theres no way i can do this jobwish i could. i also dont have any friends that know how to either. what would the average shop charge?

do it yourself...

I won't let a shop touch my car after the tranny place fucked up. Let's see...

-Brought a lift down on my door and bent the door down a good two inches, and it also buckled the lower part of the door. Ripped the heel pad off the carpet and had grease everywhere.

-They then lied about it and said I was trying to scam them.

-disconnected knock sensors

-clutch linkage failed after 14 miles

-lost my center hanger for my exhaust, causing my stock DP to break at the flex section

-fixed the linkage, broke my knock sensor

-set clutch for a preload and it would slip (fixed myself)

-linkage failed again

-fixed it

-failed again

-Finally did it myself, found that there was only 7 pieces in the throwout bearing assembly when there should be 8. Snap ring machined the retaining lip off the hub. Also lost/stripped half the bolts from tranny to engine.

Install something yourself (ALL THE INFO IS RIGHT THERE IN THE TSRM! Most shops have never touched a setup like ours, where do you think they're looking?) and you'll know it's right.

The stage 2 clutch for DM is basicly the same as mine, the clutch pedal is a BIT harder to push, but it will be very smooth like a stock clutch (that's cause it's a stock disk). It will hold more, but remember the materials in the stock disk do NOT like heat. The puck clutch will grab like a bitch when hot...

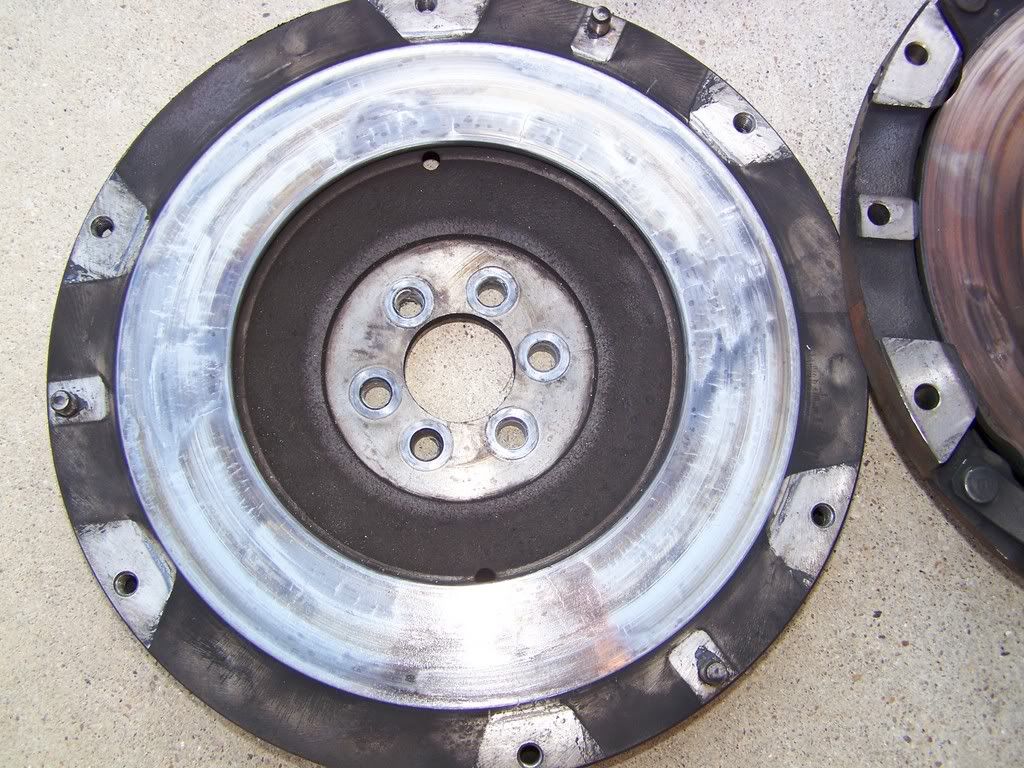

My car had to limp home with it slipping BADLY for a good 10 miles in stop and go traffic, not fun. Hence the heat that the flywheel took. A stock flywheel is great for making a harsh clutch very easy to control, as a lightweight one is easier to overheat and stall as well.

I won't let a shop touch my car after the tranny place fucked up. Let's see...

-Brought a lift down on my door and bent the door down a good two inches, and it also buckled the lower part of the door. Ripped the heel pad off the carpet and had grease everywhere.

-They then lied about it and said I was trying to scam them.

-disconnected knock sensors

-clutch linkage failed after 14 miles

-lost my center hanger for my exhaust, causing my stock DP to break at the flex section

-fixed the linkage, broke my knock sensor

-set clutch for a preload and it would slip (fixed myself)

-linkage failed again

-fixed it

-failed again

-Finally did it myself, found that there was only 7 pieces in the throwout bearing assembly when there should be 8. Snap ring machined the retaining lip off the hub. Also lost/stripped half the bolts from tranny to engine.

Install something yourself (ALL THE INFO IS RIGHT THERE IN THE TSRM! Most shops have never touched a setup like ours, where do you think they're looking?) and you'll know it's right.

The stage 2 clutch for DM is basicly the same as mine, the clutch pedal is a BIT harder to push, but it will be very smooth like a stock clutch (that's cause it's a stock disk). It will hold more, but remember the materials in the stock disk do NOT like heat. The puck clutch will grab like a bitch when hot...

My car had to limp home with it slipping BADLY for a good 10 miles in stop and go traffic, not fun. Hence the heat that the flywheel took. A stock flywheel is great for making a harsh clutch very easy to control, as a lightweight one is easier to overheat and stall as well.