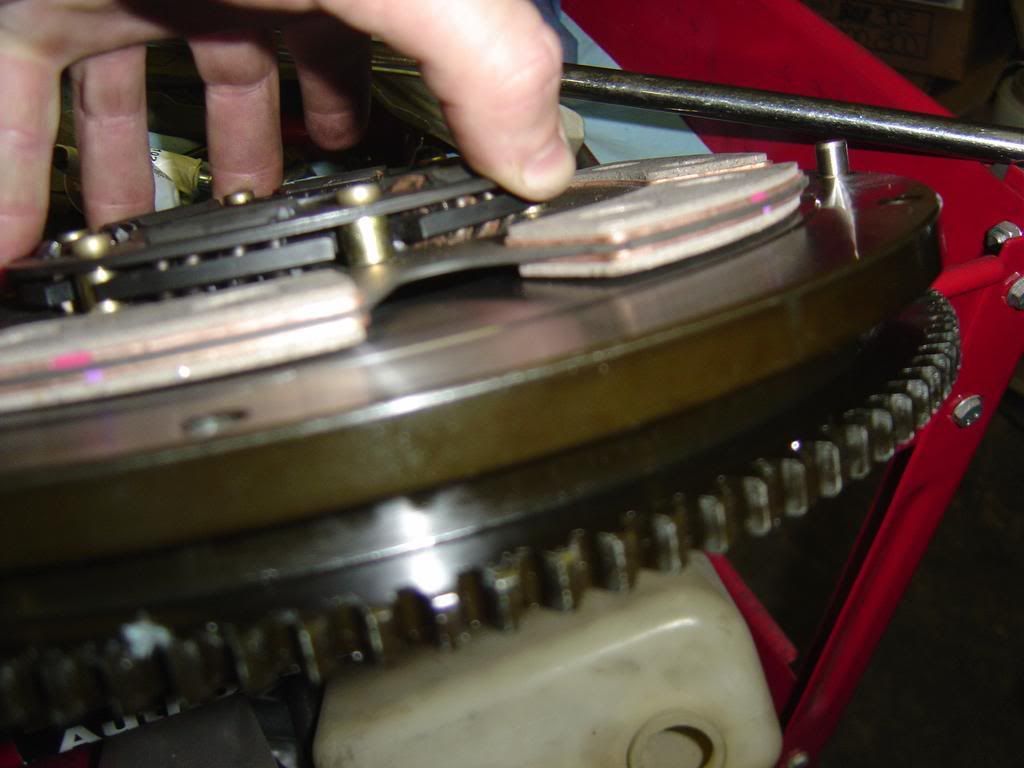

The friction discs were fine other than some possible debris damage from the broken strap and heat effects from slippage.

The pressure plate diaphragm has dowel pins and straps(springs) that keep it in place while allowing it to move forward and backward. It seems like spec is balancing the pressure plate as a whole and not the actual diaphragm. If the diaphragm is out of balance it will be pushing around inside the "balanced" pressure plate. This eventually breaks the dowel pins specifically if the engine is revved high with the clutch disengaged. The clutch would work fine during break in and with gradual throttle increases to wide open. But once I tried to "use" the clutch for burnouts, powershifts and such, it would slip frequently on the power and eventually break the dowel pin(s) and strap(s). After this, the diaphragm was dislocated and severely off balance. Imagine a sledge hammer attatched to one side of the flywheel, you could see the car shake from 50ft away.

In this thread below are pictures of mine on pg2, on pg1 are another guy's that broke a strap.

http://www.supramania.com/forums/showthread.php?t=6046

Before this would happen with the clutch, my car was so smooth that I could roll up to a stop with the windows up and all accessories off and have to check my gauges to make sure it was still running. The rotating assembly was fully balanced by the assembler.

And to clarify, I had the flywheel resurfaced and all that. Take a look at my pics again and notice the tilt of the remaining strap rivets and dowel pins, that is a building error.