***SM member 1/4 mi. times list***

- Thread starter Slow66

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Archon;2057410 said:Hi,

ET 12.13 @ 113mph (182kmh)

1JZ-GTE, T56 Magnum, Stock twins, HKS F-Con V-Pro, 430cc, VP113.

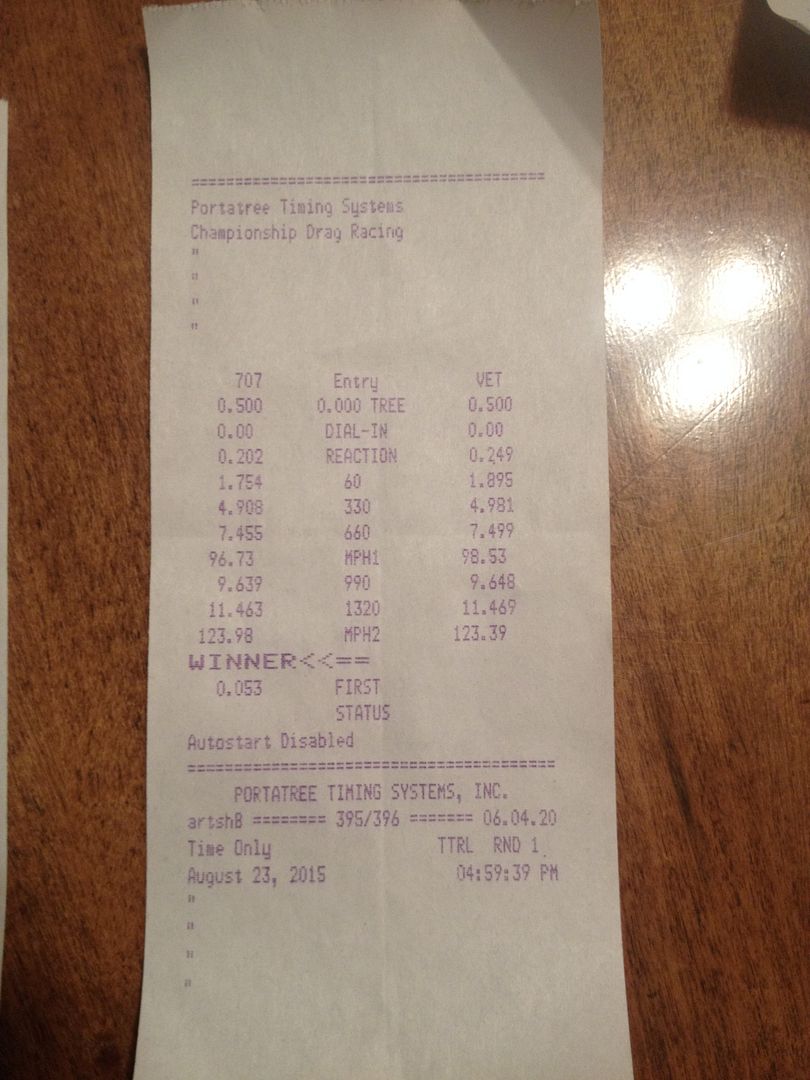

View attachment 76921

View attachment 76922

View attachment 76923

thats a fast time for that mph! whats your best 60ft with those bias ply mt's? you got some balls running those with a radial up front :aigo:

black89t;2057614 said:thats a fast time for that mph! whats your best 60ft with those bias ply mt's? you got some balls running those with a radial up front :aigo:

There is no 60ft checking on this event. My best 60ft was 1.94sec with ET12.43sec at another event. So I think last 60ft was better.

~12sec is not a problem on radial front, but front drag tires a better sure.

This is ET12.43sec run.

No burnout, because this way I havn't enough power for good start. [video]https://youtu.be/XrnPlzDUtvo[/video]

Archon;2057674 said:There is no 60ft checking on this event. My best 60ft was 1.94sec with ET12.43sec at another event. So I think last 60ft was better.

~12sec is not a problem on radial front, but front drag tires a better sure.

This is ET12.43sec run.

No burnout, because this way I havn't enough power for good start. [video]https://youtu.be/XrnPlzDUtvo[/video]

oh dam that sucks.......to run that time with that mph it had to be good prolly in the 1.7 area maybe lower!!! my buddies sti swapped legacy wagon does high 11's with like 112mph cause he launches so hard and shifts really fast. its crazy how much a good 60ft drops your time.

and the radial in front bias in rear seems to be ok if you can drive good and not make to fast of corrections even though its not recommended. ive seen videos where somebody corrects to hard and it loads one side the car to much. then the bias plys squish down too much on one side compared to the other and sends the car into the wall!

Elli;2057987 said:7M-GTE Powerglide 4X4 NP Tranferecase

View attachment 76977

[video]https://m.youtube.com/watch?v=GjqAprOBLOQ[/video]

I have to ask, what IS that car? Adapting a 7m to a 4wd system, that's really cool.

here's my slip from 10/10/15.

mods......

built 7m with wisecos, eagles

fully built/ported head with bc 272's, 1mm over valves, ti retainers

bws366, sp quick spool valve, cast t4 manifold, 3.5" exhaust, tial wg

ffim, 90mm tb, BIG treadstone intercooler, 3" i/c piping, tial bov

fid 1000's, walbro 450, fuel lab afpr, dual fed fuel rail, flex fuel sensor,e85

ms3 pro, sti coils, 26psi

princess motorsports 1pc shaft, act clutch, chromoly flywheel, beech v2 shifter.

18x10 fronts, 265-35's,

15x8 +27 rears with 275-50 nitto 555r's.

Last edited:

Dude you must be ripping those tires off on your launch, to be running that trap speed. Once you get the clutch sorted, and some practice with your 60', I could see low 11's on a good run for you.gsxr141;2060540 said:View attachment 77196

here's my slip from 10/10/15.

mods......

built 7m with wisecos, eagles

fully built/ported head with bc 272's, 1mm over valves, ti retainers

bws366, sp quick spool valve, cast t4 manifold, 3.5" exhaust, tial wg

ffim, 90mm tb, BIG treadstone intercooler, 3" i/c piping, tial bov

fid 1000's, walbro 450, fuel lab afpr, dual fed fuel rail, flex fuel sensor,e85

ms3 pro, sti coils, 26psi

princess motorsports 1pc shaft, act clutch, chromoly flywheel, beech v2 shifter.

18x10 fronts, 265-35's,

15x8 +27 rears with 275-50 nitto 555r's.

As for me, my second time to the track was this past Sunday at LVMS for Supras In Vegas. Ran 3 passes in a borrowed FR-S, all within .100 and 1mph of each other. Best run was a 15.233 at 90.65, not terrible for a 102° day in the Vegas sun. I think elevation is a little over 2000' at that track. Still think it would have run a 15.1xx with another pass, I was starting to get the car figured out.

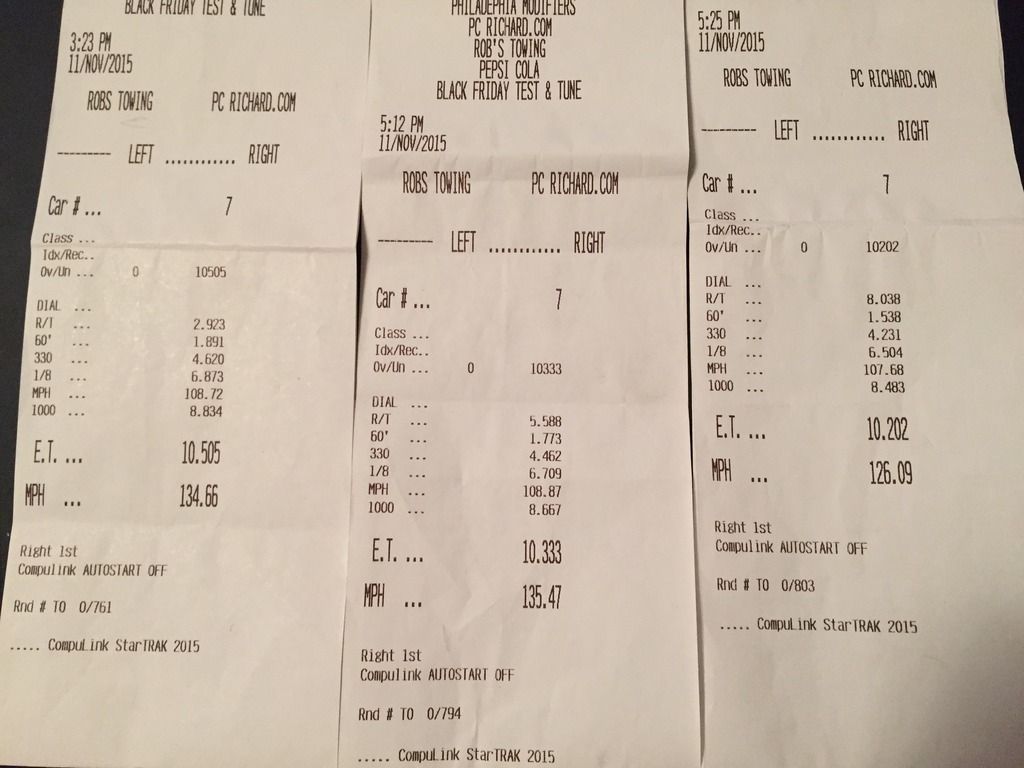

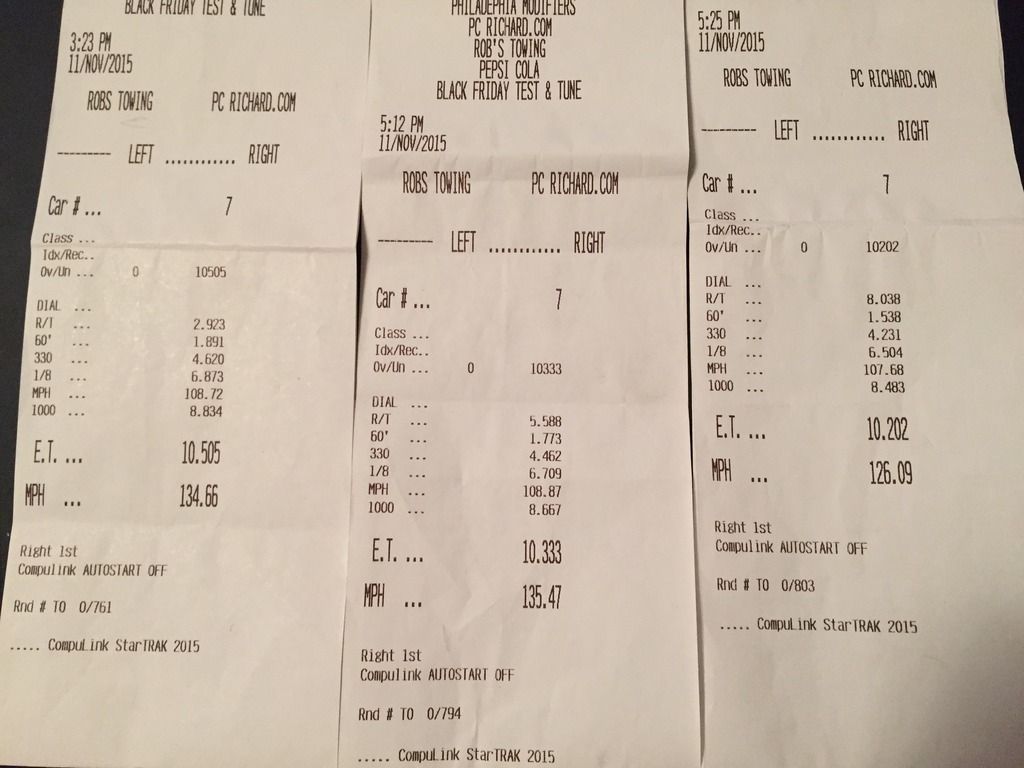

Please add me to the list!

10.202@126!

1989 Supra, 2jz, BC272, 6466, th350, Proefi.

[video=youtube;N_udPzU0FII]http://www.youtube.com/watch?v=N_udPzU0FII[/video]

10.202@126!

1989 Supra, 2jz, BC272, 6466, th350, Proefi.

[video=youtube;N_udPzU0FII]http://www.youtube.com/watch?v=N_udPzU0FII[/video]

Chunks, there is something about the sound of your car man, I like it. Question for you though. Your ET's and 60's are all somewhat close, yet your last pass is around 10mph slower, although it was your best ET by far, across all the traps. Did you let off, or have any other idea on what caused the much lower mph?

To be clear I'm not upset, I'm just a numbers guy, and I find stuff like this interesting.

To be clear I'm not upset, I'm just a numbers guy, and I find stuff like this interesting.

Thanks man! Haha. Intercooler pipe blew off on the last pass around the 1000-1100' mark. Shoulda been 9.9XX! Was pretty upset.

Ahh, that would do it. If I were more handy with a welder (heh, who am I kidding, more like handy at all haha!), I would secure my intercooler pipes like the Group A cars were set up.

They had a threaded bung welded onto each end of the piping, outside of the coupler / clamp areas. Piece of metal plate with holes in it where needed, with a bolt through it, prevented piping blowing out on the driver. Quite simple, and quite ingenious, really.

They had a threaded bung welded onto each end of the piping, outside of the coupler / clamp areas. Piece of metal plate with holes in it where needed, with a bolt through it, prevented piping blowing out on the driver. Quite simple, and quite ingenious, really.

Yea difficult to do when the end of the pipe uses an elbow coupler. It's one of the only ends that doesn't have a bead rolled in it. It blew out twice that day.

I did this homemade trick to bead roll my pipes. Search google images to get ideas. Cheap pair of vise grips and you're good to go.

Good idea to bead roll them if at all possible. As for working with an elbow coupler, attach the connecting strap in a way to act like the bottom of a triangle, from the side you can access. Might have to do both sides, but I think it would work.

Also, constant torque clamps work wonders for high pressure applications, it's pretty much the only type of clamp Cat sells for turbo piping...

Also, constant torque clamps work wonders for high pressure applications, it's pretty much the only type of clamp Cat sells for turbo piping...

Well all my clamps are Turbonetics brand T-Bolt design from summit. Like these http://www.summitracing.com/parts/tnt-30275-300

They usually hold up fine, but i never had my boost up that high before. Im sure if i had rolled a bead into the end of the pipe it wouldnt have come off. But the straight flat pipe just slid right out.

Best way to do it is Van-Jen flanges but they are serious $$$$ and also require the pipes to fit up nearly perfectly. For my purposes, bead rolled pipe and silicone couplers secured with T-Bolt clamps will be fine.

They usually hold up fine, but i never had my boost up that high before. Im sure if i had rolled a bead into the end of the pipe it wouldnt have come off. But the straight flat pipe just slid right out.

Best way to do it is Van-Jen flanges but they are serious $$$$ and also require the pipes to fit up nearly perfectly. For my purposes, bead rolled pipe and silicone couplers secured with T-Bolt clamps will be fine.

yeah you need to bead roll your intercooler pipes. i was getting boost leaks on higher boost till i did that at all joints. harbor freight has a nice bead roller that worked really good on mine. i used some angle iron bolted to the end to keep the rollers from spreading. besides doing that its pretty simple. you had to be running more than 550whp 135 trap speed is like closer to 700whp im pretty sure!

Yea I made 560 at 23psi and was running 30 at the track.

All my pipes have beads except that one end.

All my pipes have beads except that one end.