Well, I don't; and ebay didn't tell me it was, Grand Rebuilder's did. I spoke with them on the phone and the rep stated that the cores are rewound with more wire providing higher output than oem (weird thing is the alt is roughly 30% smaller than my factory one). When I asked about other rebuilders selling alt's advertised as 160amp output he stated that Grand Rebuilder's rewire the alt's as large as possible (which apparenlty is 130amp). The higher amperage rebuilt alt's out there must be rated without a load. His 130amp alts are rated under load. Now this may all be a total crock, but $89 shipped for a rebuilt alt is a good deal no matter what it outputs.

I did not "have" to buy the smaller pulley; I simply did. I was told that alternators peak outputs are rated at a fairly high rpm (6500rpm or something). The factory alternator maybe puts out like 10amps at idle. The higher output ones do something like 12-15amps at idle. To combat this, if you go with a smaller than factory pulley, the alternator spins faster at idle producing more output at lower rpm's. The downside is that the alternator spin faster at higher rpm's and therefore can damage the alternator (they begin to self destruct at around 16000rpm's). The way I see it, I won't be in the higher rpm's for prolonged amounts of time and if the alt dies, they're only $89 and 15min to replace.

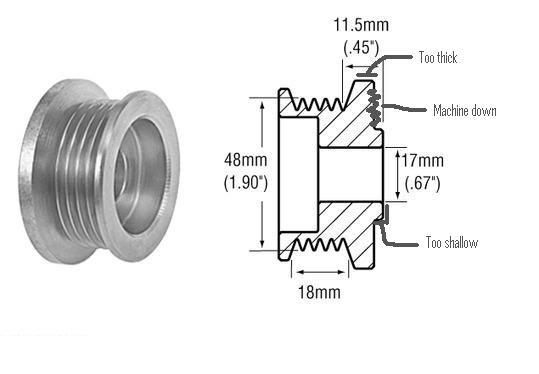

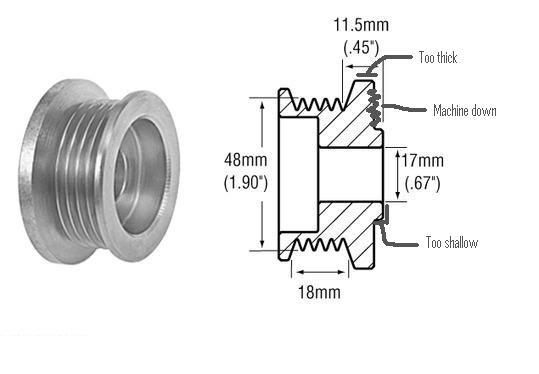

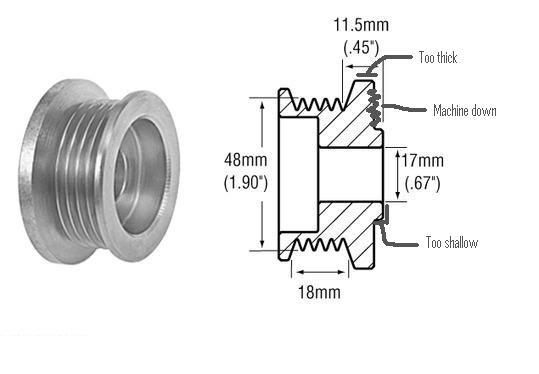

As far as the pulley is concerned, I looked all over the place for a compatible 48mm pulley for our alts. Well, there is none. However, the pulley off of a 81-88 Mercury is damn close. The only issue is the rear lip is too thick pushing the belt forward just a bit (not a big deal), but the contact point of the pulley to alternator is several mm to shallow and therefore the pulley just rests on the cover (not good for performance, but the sparkshow is awesome). Originally I was going to place a washer on the alternator's stud to resolve this, however, then the front of the pulley becomes too shallow for the nut to thread on the bolt and the pulley is now even farther forward then before.

Kills two birds with one stone. Not only increases the depth of the pulley's contact surface, but also reduces the thickness of the rear lip, making the pulley fit the alternator perfectly and placing the belt at the correct angle. Any machine shop with an ounce of skills should be able to knock this out for you in under 30 minutes. I don't have the exact dimensions that need to be shaved off, but if you leave the shop the alternator then they should be able to figure it out.

I am not a technitian, nor have I had a chance to run this alternator. Currently it is just test fit and appears to bolt-up just fine, however, real world output and reliability is unknown.

Don't ask about the alt position. Currently waiting on the lower adjustment bracket from Seth. :biglaugh:

That's all the info I can provide. Hope someone finds this useful.