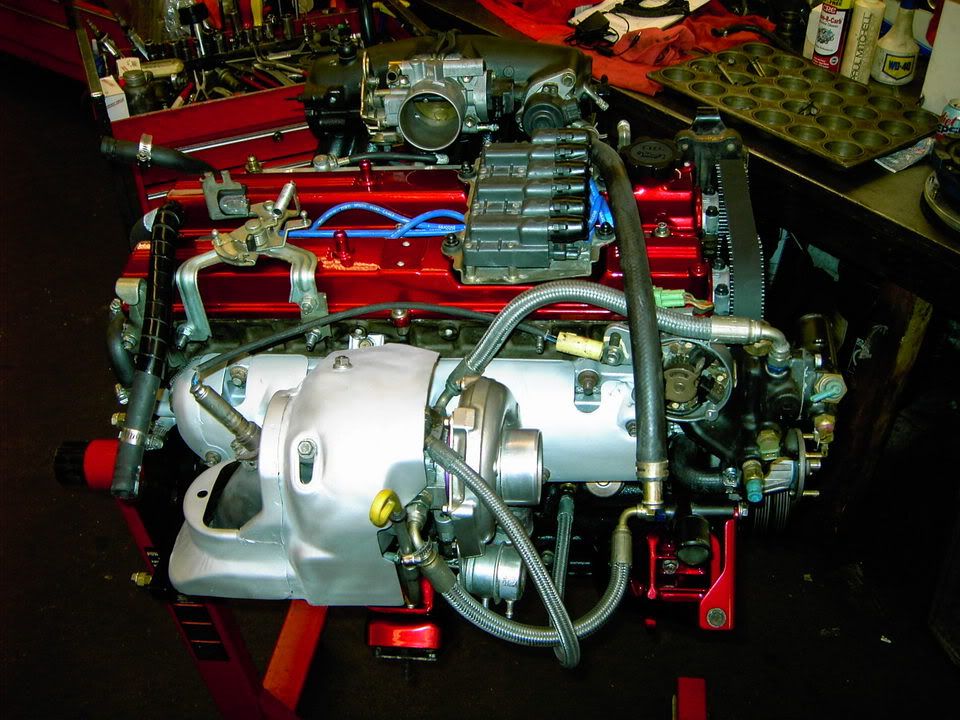

Can't take credit for the muffin pan idea. (The shop who did the machine work, and allowed me to assemble the final motor in the off hours uses many of these pans for every engine that is being worked on.)

They basicly have many motors in various states of rebuilding, and they keep each one seperate in various muffin pans that stick with the engine through the process. (They also have a nice wall of new nuts and bolts, and any ones that are in good shape get recycled as some fastners are very difficult to find, or are pretty dang expensive.) Good example is your exhaust studs. At about a 1.50 each, they are not cheap.