I'm putting an oil temp gauge in my Supra and I was wondering if anyone had any suggestions on where to locate the oil temp sender that came with the gauge?

oil temp sending unit

- Thread starter suprabad

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

shaeff said:hey suprabad, long time no see! welcome back.

when i hook up my oil temp gauge, i'm going to drill a hole in the drain plug, and locate it there.(always in the oil)

-shaeff

idk if the threads and stuff are the same but this is available for my car. maybe it would work for supras too

http://www.courtesyparts.com/Merchant2/merchant.mvc?Screen=PROD&Product_Code=11128-RN010&Category_Code=

Goes in between your oil filter and mount and is already pre-drilled for oil temp and oil pressure lines.

shaeff said:hey suprabad, long time no see! welcome back.

when i hook up my oil temp gauge, i'm going to drill a hole in the drain plug, and locate it there.(always in the oil)

-shaeff

Thanks Bud...I've been lurking.

I saved the file of you sliding around in your supra...having followed your build up, it was great to see it run and you driving it.

Question...are you saying drill a hole in the drain-plug and tap threads for the sensor? Come to think of it that kinda makes sense. At least if you screw it up it's just a drain plug and not a hole in you're block or oil pan or.....!

okeee dokeee

Thats what I use for oil temp/pressure, mine doesn't quite look like that (that must be an older one or something) but its the same thing.Bishop92t said:

Goes in between your oil filter and mount and is already pre-drilled for oil temp and oil pressure lines.

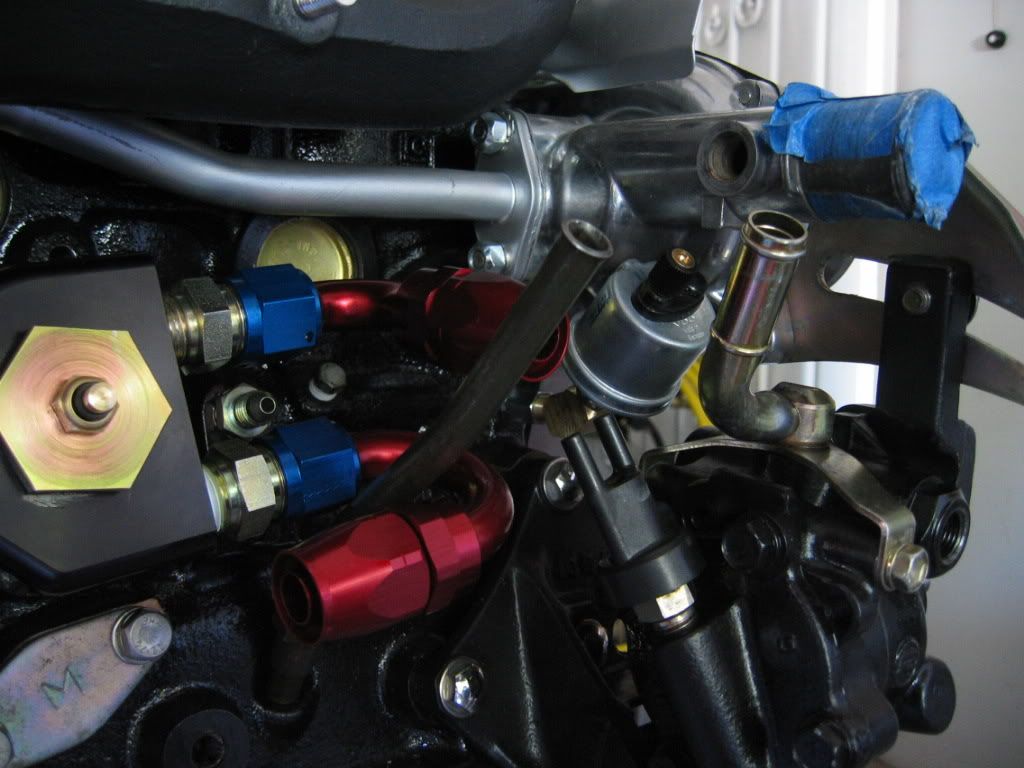

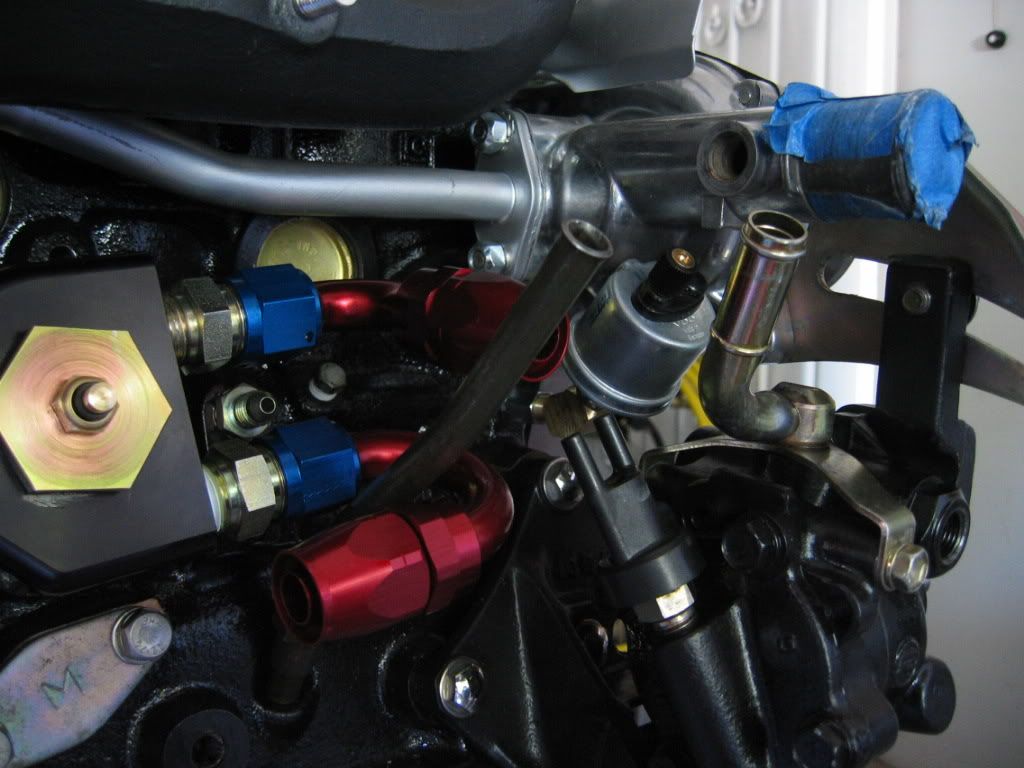

Here's where I put mine. You can see on the left of the picture, I drilled/tapped into the big bolt on the oil filter adapter.

bishop, i've relocated my oil filter to the passenger side tow hook, and am running an 11x8 B&M oil cooler, and 180* B&M thermostat. would i hook that up to the relocation kit near my tow hook? or right off the block. there's not much room off the block, as the lower I/C pipe is right there, and it's a tight fit as it is.

heh, that's pretty neat! damn NISMO making all kinds of nissan stuff!

i sure am. that was my thought! and thanks for the comment.

that was my thought! and thanks for the comment.

racefeind, your setup looks MINT! i want more pics, too!

-shaeff

styin'ser said:idk if the threads and stuff are the same but this is available for my car. maybe it would work for supras too

http://www.courtesyparts.com/Merchan...Category_Code=

heh, that's pretty neat! damn NISMO making all kinds of nissan stuff!

suprabad said:Question...are you saying drill a hole in the drain-plug and tap threads for the sensor? Come to think of it that kinda makes sense. At least if you screw it up it's just a drain plug and not a hole in you're block or oil pan or.....!

okeee dokeee

i sure am.

racefeind, your setup looks MINT! i want more pics, too!

-shaeff

Last edited:

isnms said:what about here?

pic borrowed from GrimJack

Would work if the sensor was short so it didn't block flow in the gallery.

Heres a few pics. All the good stuff is on the inside. The outside looks all stock :naughty: Only running 7psi for now. It is in my mk2 though, not the mk3

theres a few more pics here:

http://smg.photobucket.com/albums/v339/Racefiend/MK2/

theres a few more pics here:

http://smg.photobucket.com/albums/v339/Racefiend/MK2/

Hey Racefiend, that sender setup on the right is bad news. When you have a big sender with a lot of mass and mount it using a brass fitting with a long moment arm you're just asking for a fatigue failure. Seen it happen more than a few times. If I were you I'd replace that fitting with steel or support the sender.

IHI-RHC7 said:Is that electron blue pearl?

It's actually dark cloissone blue metalic. Comes from the mid/late 90's corvette.

Jetjock, interesting point you make. I could see if it was copper that it might cause problems, but brass? I'll see if I can find some steel fittings and replace them next time I'm working in that area just for insurance. It will be hard finding a steel 45 female-female like that one. I assume I should only have to worry about the male-male, though, as that female-female 45 should be thick enough to hold it's own. Thanks for the tip :bigthumb:

OK, I went back and looked again and now I'm confused (lol, happens often). Does that fitting go into the block or is it on a flex line? If on a line forget what I said. If in the block yeah, try and replace it with steel. Brass, like aluminum, has a finite fatige life even if the loading is kept within the elastic region. Steel doesn't. Just a fancy way of saying you can bend steel a little bit forever without fatiguing it but not so with brass or aluminum.

I'm generalizing here because there are lots of alloys of brass and aluminum but what I've stated is generally true. And yes, you only need to worry about the block end (assuming it even goes into the block) as the greatest cyclic loading will be there, on a thread and a small diameter to boot.

I can't tell how much mass the sender has though. For all I know it's a lightweight. It's just the airplane mechanic and engineer in me talking plus I've seen such setups fail before. Some time will pass and and then boom, it'll fatigue fracture. That said it'll "probably" be OK as is but if it were me I wouldn't risk it, especially if that's oil.

I'm generalizing here because there are lots of alloys of brass and aluminum but what I've stated is generally true. And yes, you only need to worry about the block end (assuming it even goes into the block) as the greatest cyclic loading will be there, on a thread and a small diameter to boot.

I can't tell how much mass the sender has though. For all I know it's a lightweight. It's just the airplane mechanic and engineer in me talking plus I've seen such setups fail before. Some time will pass and and then boom, it'll fatigue fracture. That said it'll "probably" be OK as is but if it were me I wouldn't risk it, especially if that's oil.