I posted on another forum and I wanted to see what this forum has to say. I've already purchased a bunch of parts but I'm looking for some more input. I'm going to add the few posts I've had over the last few weeks to this one. Thanks

An unconventional start to a build thread, but I have some questions that are going to affect how the build goes so I figured I’d start a thread now with my questions and just continue to fill it with information as I go. Maybe it’ll work out, maybe not. I’ve built many motors in my day but this will be my first 7M and want to get some questions out of the way. After all the reading I’ve been doing over the last couple of years, I will be posting my perspective from what I’ve read/learned and I am looking for input/corrections. Please no jz vs. 7m, no lie, I probably read them all already. I will be posting pics and editing along the way. I’ll get some pics up later today.

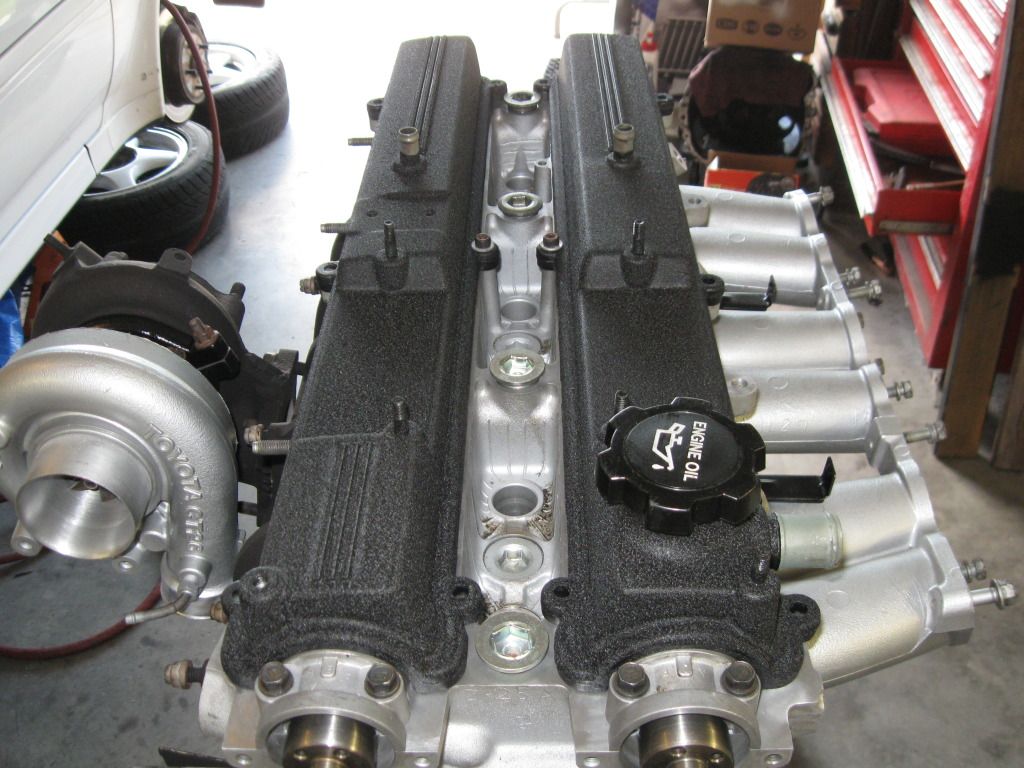

Cliff note story : 3/11/10 Bought car at 190K with 60-1 ct and 3” turbo back, PO replaced BHG at 180K (Composite gasket, ARP’s, Head decked?, Block never removed ), ~last year I’ve been doing BPU’s and maintenance/rebuilding stuff, Rolled 220K and blew HG last weekend, pulled everything out, stretched #6 to the coolant passages and cylinder had water , #1 is also stretched but no water, never overheated, water never made it to the oil , all main/rod bearing surfaces are fine, intake cam has very little scoring on the second journal (the one under the oil cap), all oil/coolant passages in block and head are clean, very clean for 220k, block gutted, head dissembled, brings us to the now. Short and sweet!

I’m looking for just a freshening up, if you will, and will be putting in a MHG properly. I think I’ll be happy at ~400-450whp when finished here so, according to my research, OEM level internals are just fine.

Ok, Bottom to top

Main/Rod Bolts: Are Arp’s necessary for what I’m looking for? I won’t be re-using anything here so new OEM vs. ARP’s. I’m most likely going the ARP route anyway, just for peace of mind, but anyone please fill in the blanks for me.

Bearings: I see Cleveite, ACL, King and OEM as top choices. I still have all the Toyota stamps, but I will be measuring up everything anyways. Input on bearings?

Rods: I read that the OEM rods are fine here for my goals? Any suggestions for machine work?

Oil pump: I haven’t broken it down yet but I will be shimming the relief valve and coating the gears. Is an aftermarket feed line necessary?

Oil pump shaft: Bearing surfaces and clearances are great here so no new bearings but I will be machining off the old fuel pump lobe area and the old distributor gear area as well per sixpack’s method. Sixpack, would you mind posting those pics in here, I looked around, but forget where you posted them before, thanks.

Pistons/Rings: I read plenty on the OEM pistons but nothing really concrete, except to stay away from Probe. Are the stockers OK? What’s the “OEM quality” aftermarket like? NPR?

Gasket: For my goals, what would the best choice be for a MHG? I haven’t measured the surfaces yet, just rough checked with a straight edge, but let’s assume minimal material removal.

Valves: I don’t think I need to do anything here as far as over sizing, I will be lapping them back in though and re shimming of course.

Valve Seals: I’ve read many things hear but what’s best? Fel-Pro? Viton?

Valve Springs: I read that the SBC springs will be a perfect little upgrade here for me. Comp Cams correct? Yea or Nay? Keep the stockers?

Retainers/locks: I read OEM will be just fine here, and up to 264’s. Am I good here?

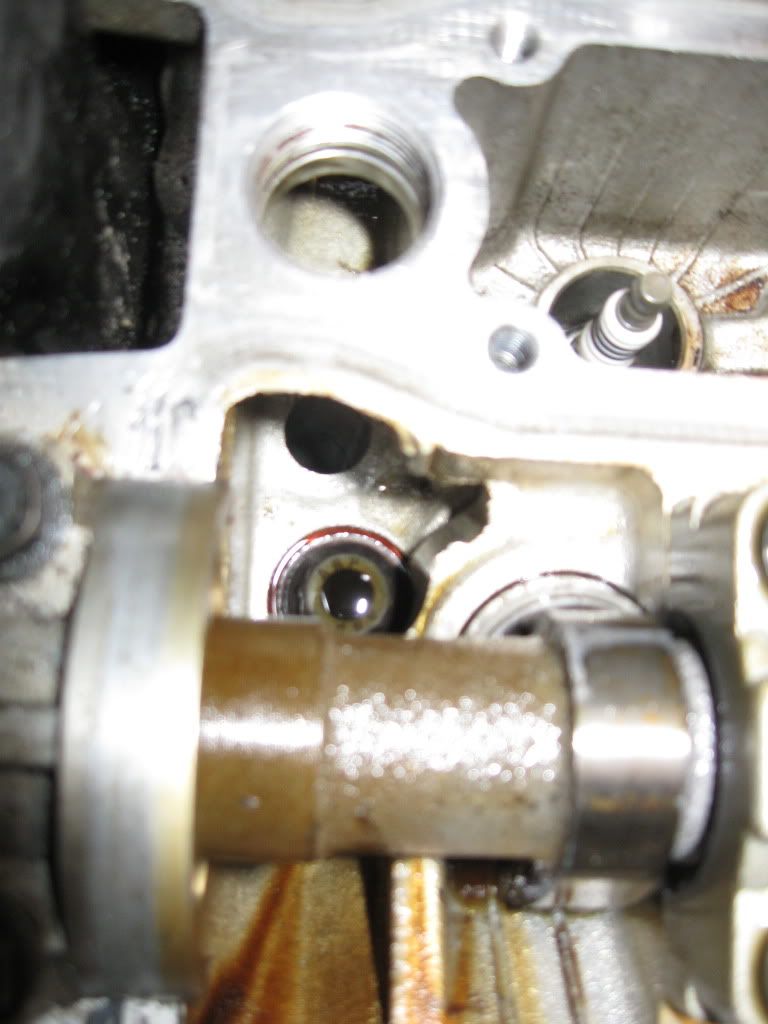

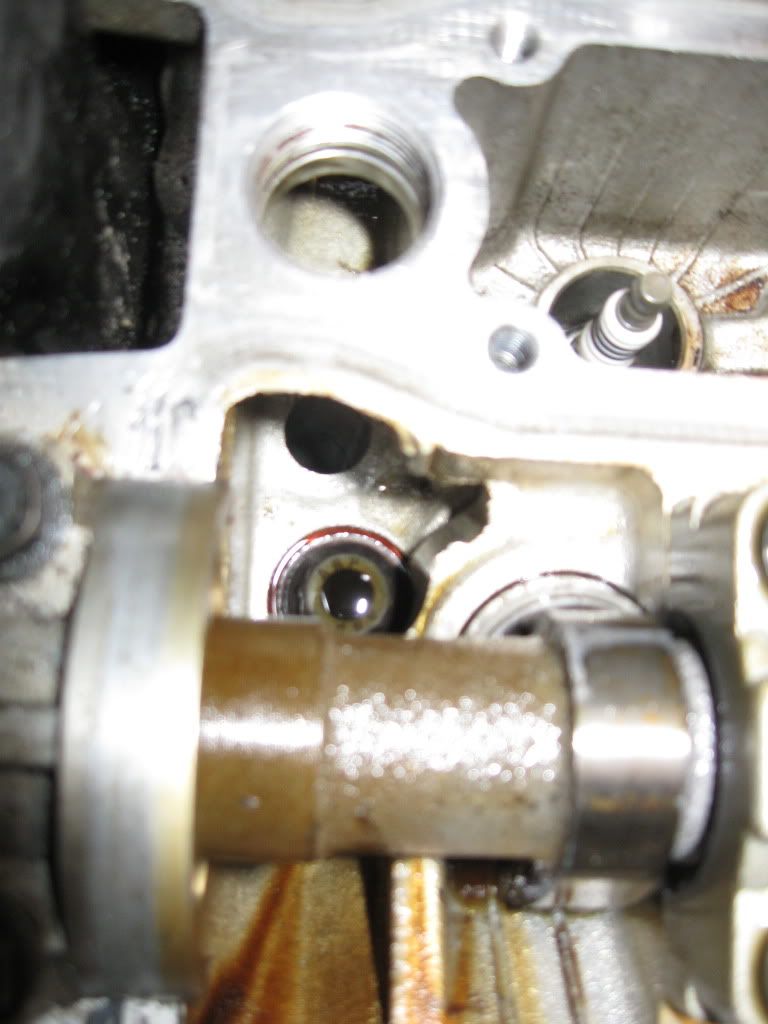

Cams: For my goals OEM should be fine here, right? What would 264’s do for me? As mentioned the intake cam second journal has some scoring but the head and cap are perfect and I remember reading somewhere that this is a common galling problem here, input? It’s not terrible but I’m going to polish it up anyways.

Here are some pics of the car when I got it and now and some cell phone pics of 1&6.

#6

#1

Thanks in advance to all that help out here.

Taking block and head to machine shop

Machinist surprised me and pushed me up the list, had had to take 0.30mm of the block and 0.23mm off the head. Which brings me to my next question, Where is the 7M happy as far as compression ratio? To stay stock I'd be at a 1.8mm gasket, what would a 1.4mm do for me as far as compression?

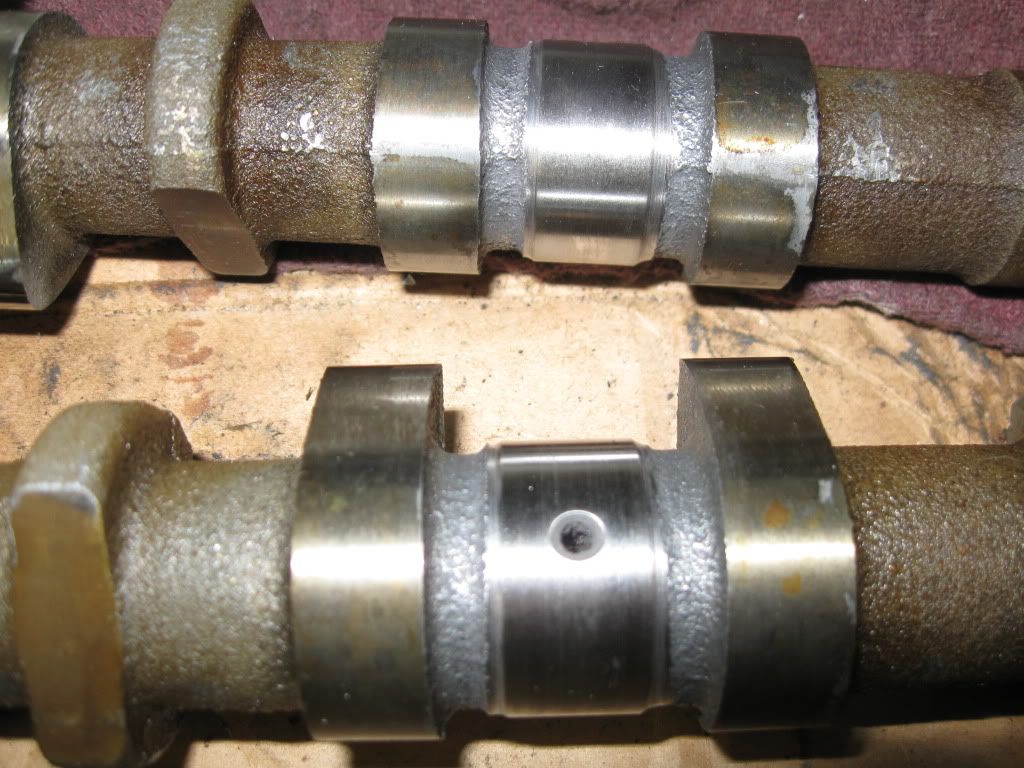

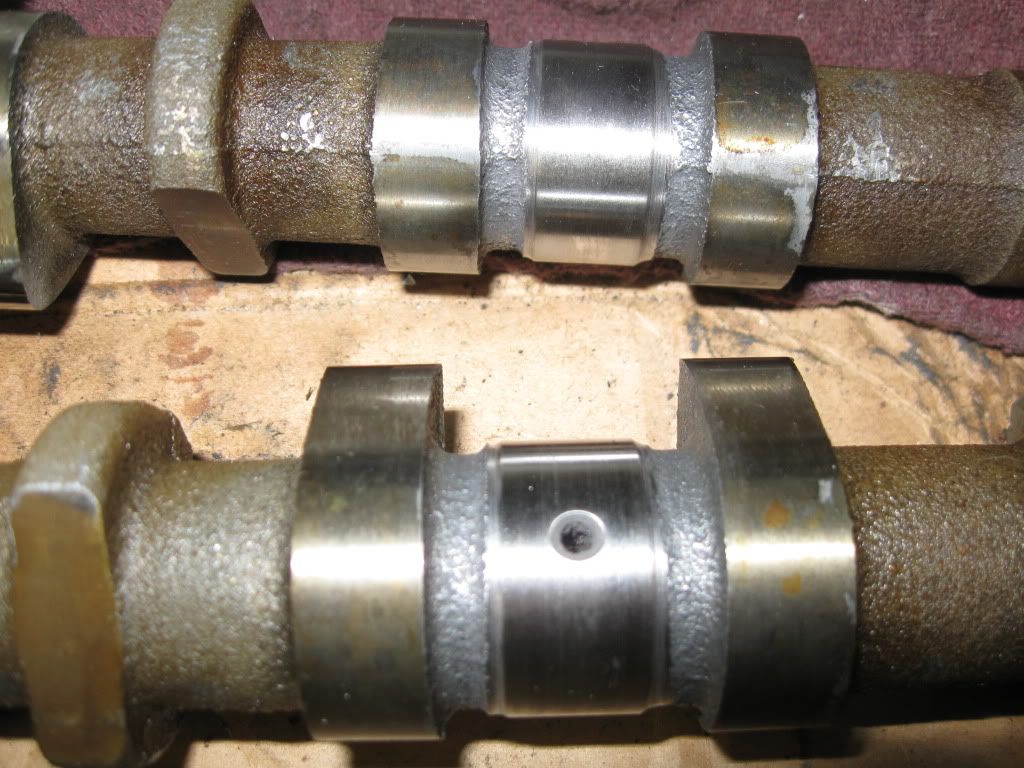

Got the cams all polished up today. I chucked them up in the lathe and just took some scotch-brite strips to them. I think they cleaned up real nice. I had some dragging spots when placed in the head and spun by hand, now its all smooth.

Before

After

Started cleaning all the slag off the head intake ports, its taking time but clean up real nice. There's a huge ridge behind every valve seat on the port side, just cleaning these up must make a difference.

I still need to polish this some more but you get the idea.

I'm reading not to touch the exhaust side, as far as porting, because of the negative result of exhaust velocity between the valve and the turbo. What do you guys think about that? I was thinking of going in and at least clean up the slag so its smoother, think its a good idea or what?

I also need a little insight on happy compression ratio and the 7mgte, if anyone wants to school me?

Today I've been working on getting the head back together, cleaning valves and lapping them back in, springs and get new shim measurements.

An unconventional start to a build thread, but I have some questions that are going to affect how the build goes so I figured I’d start a thread now with my questions and just continue to fill it with information as I go. Maybe it’ll work out, maybe not. I’ve built many motors in my day but this will be my first 7M and want to get some questions out of the way. After all the reading I’ve been doing over the last couple of years, I will be posting my perspective from what I’ve read/learned and I am looking for input/corrections. Please no jz vs. 7m, no lie, I probably read them all already. I will be posting pics and editing along the way. I’ll get some pics up later today.

Cliff note story : 3/11/10 Bought car at 190K with 60-1 ct and 3” turbo back, PO replaced BHG at 180K (Composite gasket, ARP’s, Head decked?, Block never removed ), ~last year I’ve been doing BPU’s and maintenance/rebuilding stuff, Rolled 220K and blew HG last weekend, pulled everything out, stretched #6 to the coolant passages and cylinder had water , #1 is also stretched but no water, never overheated, water never made it to the oil , all main/rod bearing surfaces are fine, intake cam has very little scoring on the second journal (the one under the oil cap), all oil/coolant passages in block and head are clean, very clean for 220k, block gutted, head dissembled, brings us to the now. Short and sweet!

I’m looking for just a freshening up, if you will, and will be putting in a MHG properly. I think I’ll be happy at ~400-450whp when finished here so, according to my research, OEM level internals are just fine.

Ok, Bottom to top

Main/Rod Bolts: Are Arp’s necessary for what I’m looking for? I won’t be re-using anything here so new OEM vs. ARP’s. I’m most likely going the ARP route anyway, just for peace of mind, but anyone please fill in the blanks for me.

Bearings: I see Cleveite, ACL, King and OEM as top choices. I still have all the Toyota stamps, but I will be measuring up everything anyways. Input on bearings?

Rods: I read that the OEM rods are fine here for my goals? Any suggestions for machine work?

Oil pump: I haven’t broken it down yet but I will be shimming the relief valve and coating the gears. Is an aftermarket feed line necessary?

Oil pump shaft: Bearing surfaces and clearances are great here so no new bearings but I will be machining off the old fuel pump lobe area and the old distributor gear area as well per sixpack’s method. Sixpack, would you mind posting those pics in here, I looked around, but forget where you posted them before, thanks.

Pistons/Rings: I read plenty on the OEM pistons but nothing really concrete, except to stay away from Probe. Are the stockers OK? What’s the “OEM quality” aftermarket like? NPR?

Gasket: For my goals, what would the best choice be for a MHG? I haven’t measured the surfaces yet, just rough checked with a straight edge, but let’s assume minimal material removal.

Valves: I don’t think I need to do anything here as far as over sizing, I will be lapping them back in though and re shimming of course.

Valve Seals: I’ve read many things hear but what’s best? Fel-Pro? Viton?

Valve Springs: I read that the SBC springs will be a perfect little upgrade here for me. Comp Cams correct? Yea or Nay? Keep the stockers?

Retainers/locks: I read OEM will be just fine here, and up to 264’s. Am I good here?

Cams: For my goals OEM should be fine here, right? What would 264’s do for me? As mentioned the intake cam second journal has some scoring but the head and cap are perfect and I remember reading somewhere that this is a common galling problem here, input? It’s not terrible but I’m going to polish it up anyways.

Here are some pics of the car when I got it and now and some cell phone pics of 1&6.

#6

#1

Thanks in advance to all that help out here.

Taking block and head to machine shop

Machinist surprised me and pushed me up the list, had had to take 0.30mm of the block and 0.23mm off the head. Which brings me to my next question, Where is the 7M happy as far as compression ratio? To stay stock I'd be at a 1.8mm gasket, what would a 1.4mm do for me as far as compression?

Got the cams all polished up today. I chucked them up in the lathe and just took some scotch-brite strips to them. I think they cleaned up real nice. I had some dragging spots when placed in the head and spun by hand, now its all smooth.

Before

After

Started cleaning all the slag off the head intake ports, its taking time but clean up real nice. There's a huge ridge behind every valve seat on the port side, just cleaning these up must make a difference.

I still need to polish this some more but you get the idea.

I'm reading not to touch the exhaust side, as far as porting, because of the negative result of exhaust velocity between the valve and the turbo. What do you guys think about that? I was thinking of going in and at least clean up the slag so its smoother, think its a good idea or what?

I also need a little insight on happy compression ratio and the 7mgte, if anyone wants to school me?

Today I've been working on getting the head back together, cleaning valves and lapping them back in, springs and get new shim measurements.