limequat;1417974 said:

Cool. How do ensure that you don't blow through with your spot welds?

Canuckrz;1418183 said:

Very very interesting, but do you think those spot welds will be strong enough taking into account how thin the metal on the shock is?

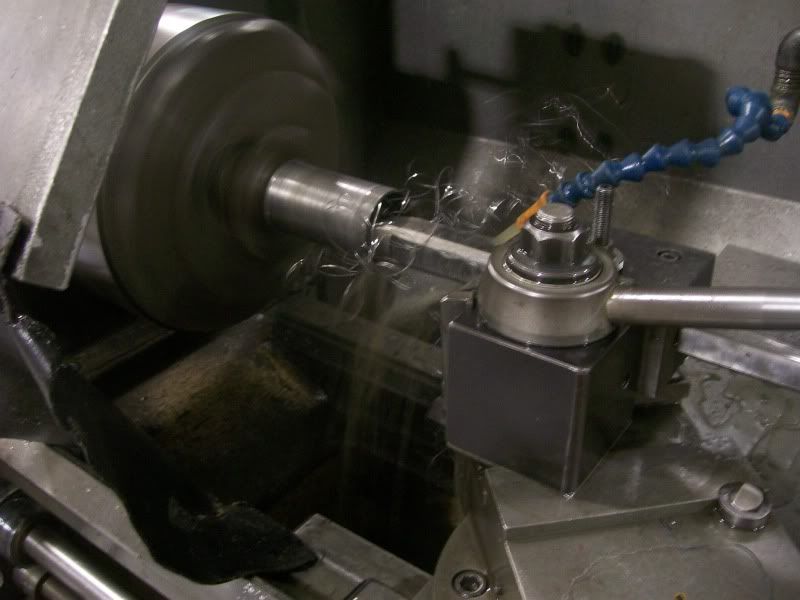

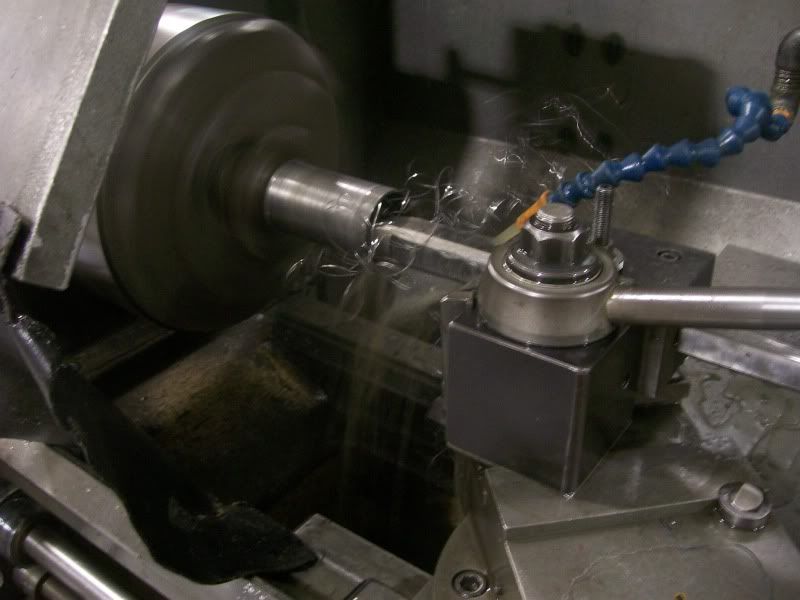

The trick here is keeping heat dissapation in mind in order to make a strong secure weld without overheating or distorting the shock/strut. So I used a piece of tube withe the greatest amout of mass to absorb the heat from this spot type weld. I also used a chamfered hole so that there was good bonding between the tube and the shock at the beginning of the weld, and then dissapate into the sleeve.

kotu100;1417989 said:

*sigh* this is why i miss bein a machinist....

good job, make sure you post up the finished product.

what sleeves are those? what springs are you gonna use with em?

They're QA1 sleeves, and I plan on using the stock springs to start with. I'm still working on the perches. I'll post more pics as I go.

Mk3runner;1418061 said:

Thanks! nice to see another norcal member!

limequat;1418399 said:

I'm sure it's fine. Strut perches are built similarly.

exactly. those spot welds have lots of strength, plus it's sweated on. It's not going annywhere.