I want to remove the crank case ventalation pipe from the cam covers, possable or not? and if it is what exactly can i do with it, Ie. can i just instal a length of piping with a filter on the end of it or do i need to make some sort of oil catch and drain for it?

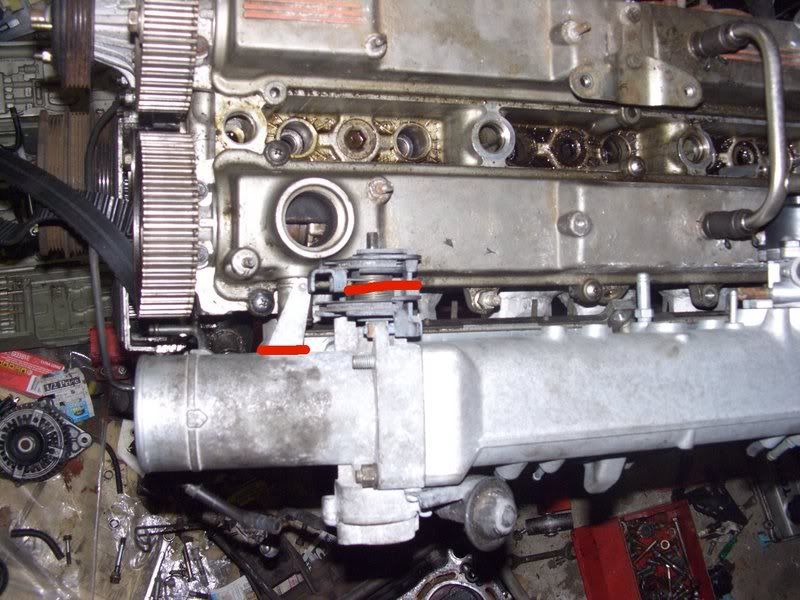

heres some pics of what ive done. if you didnt catch my post on the jz tech.

Front turbo side clicky

Bottom of intake fitment clicky

OMFG IM ON TOP clicky

My issues so far, kick down connection hitting cam cover

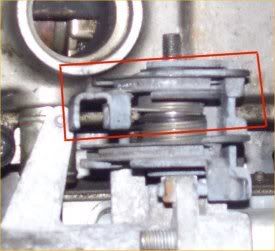

TPS sensor

and possably cold start (havent tested fitting) Okay cold start valve looks like it will be okay. 1 bolt doesnt line up but an easy fix.

Good news tho, with little modifying ports line up

intake stands the same height from top of the ports in the head (ruffly 7inches for both)

Looks a F'k load better then over the head 7m intake.

.Dave

heres some pics of what ive done. if you didnt catch my post on the jz tech.

Front turbo side clicky

Bottom of intake fitment clicky

OMFG IM ON TOP clicky

My issues so far, kick down connection hitting cam cover

TPS sensor

and possably cold start (havent tested fitting) Okay cold start valve looks like it will be okay. 1 bolt doesnt line up but an easy fix.

Good news tho, with little modifying ports line up

intake stands the same height from top of the ports in the head (ruffly 7inches for both)

Looks a F'k load better then over the head 7m intake.

.Dave

Last edited: