IJ - it apparrently goes; if the head isnt flat when you start doing the machining, and you're trying to make it flat from being banana'ed, even slightly, you'll bugger the journals when you put the cam back in, because several of them will be out of true.

Of course i guess line boring them would be an option then, but ideally you don't want to be doing that in the first place!

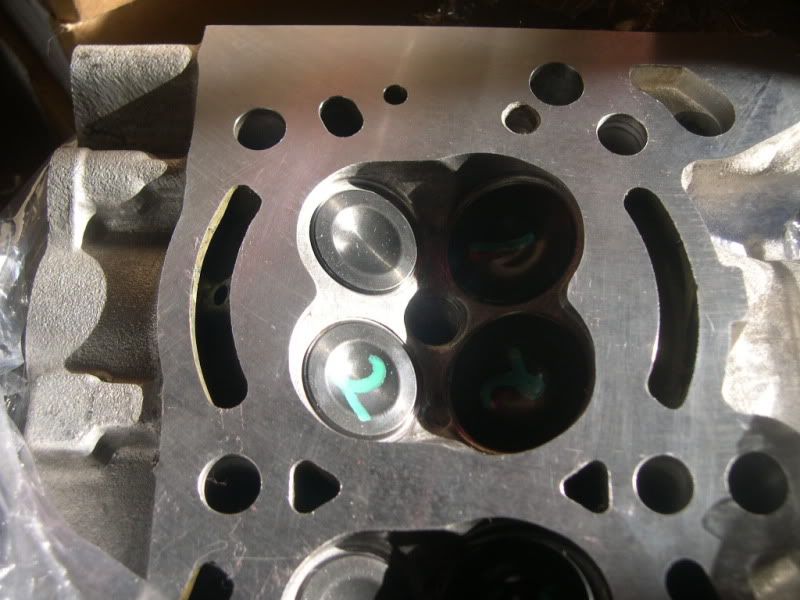

I'll be going to pretty much the only machine shop in the south of england - SERDI:

http://www.serdi.co.uk/

Sorry if these sound like dumb questions, but its better to ask those that KNOW and have done it before, than relying on second hand information that seems dubious.